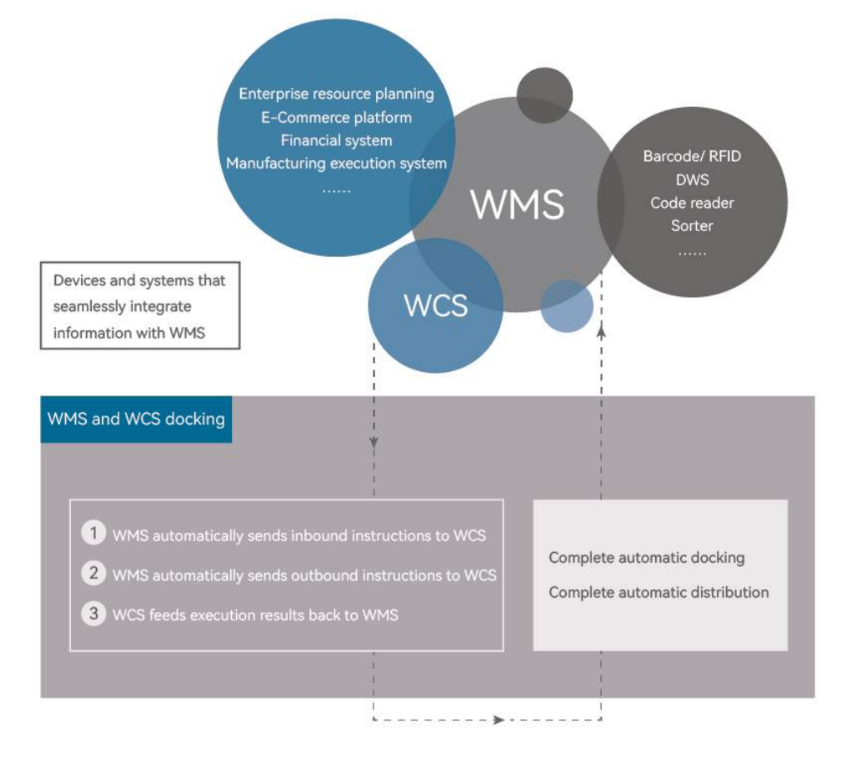

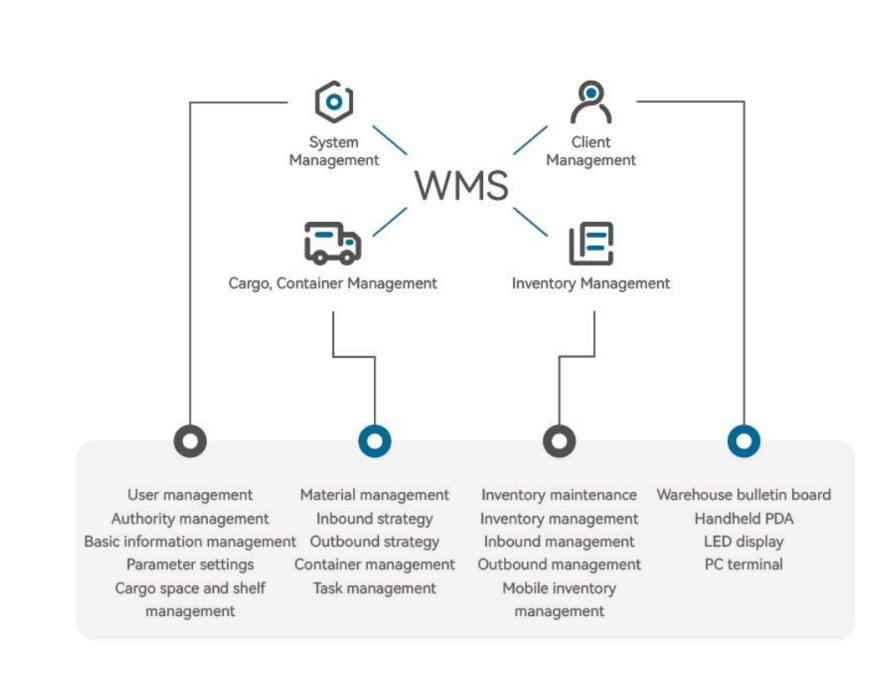

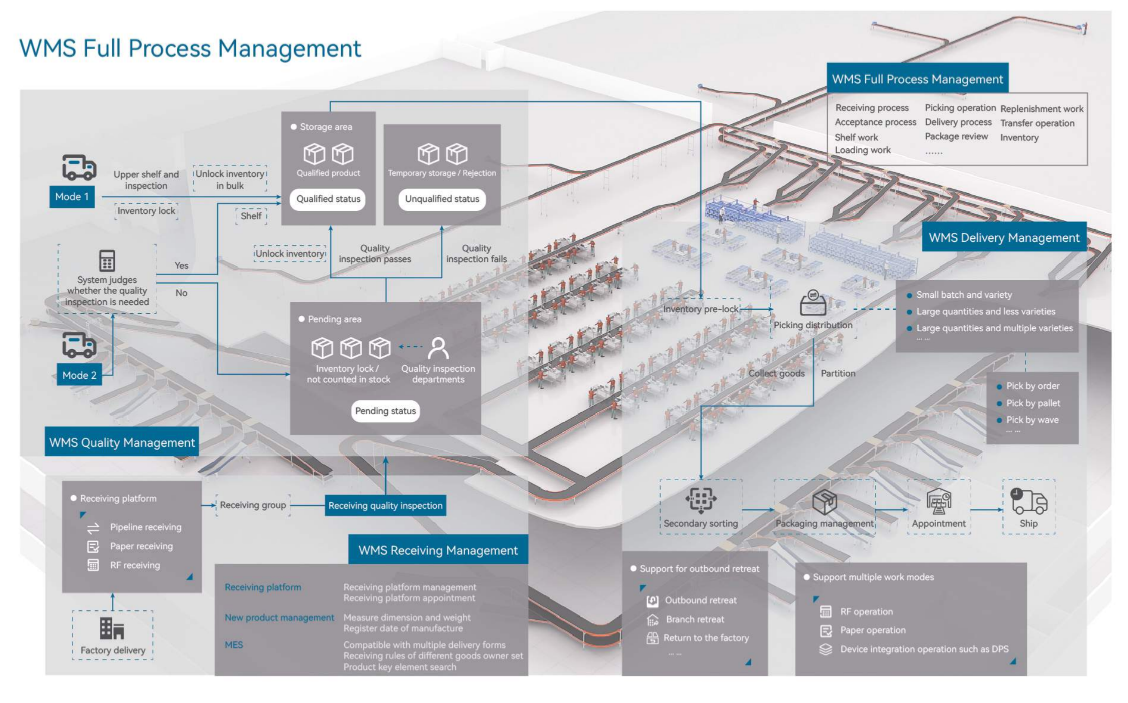

Warehouse Management System (WMS) is a software information system for fine management of warehouse goods, storage location, and quantity which is connected to ERP (Enterprise Resource Planning Management System), MES (Manufacturing Execution System), and WCS (Warehouse Control System). It is the extension and supplement of the warehouse management module in ERP and the source of WCS tasks. Through various business policies and intelligent algorithms, different tasks are issued to WCS.

Wayzim WMS supports dynamic allocation strategies for various storage locations, supporting various outbound strategies such as FIFO, LIFO, designated vendor priority, and is able to support the customisation of corresponding strategies to meet the demands of customers for various business management of intelligent warehouses.

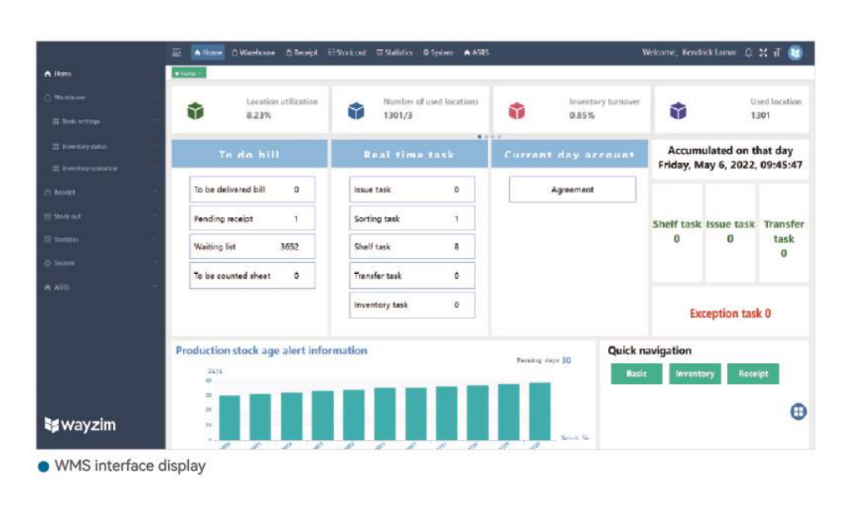

Warehouse Management System – Full Process Management

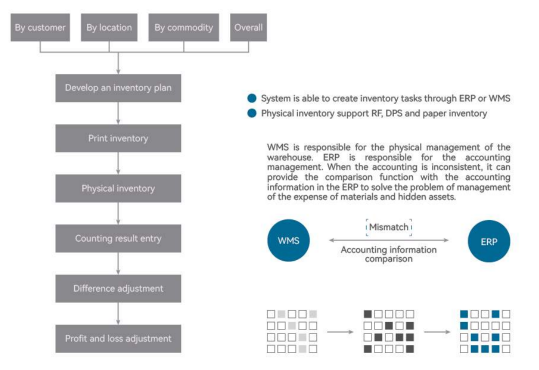

Warehouse Management System – Inventory Management

*WMS is responsible for the physical management of the warehouse. ERP is responsible for accounting management. When the accounting is inconsistent, it can provide a comparison function with the accounting information in the ERP to solve the problem of managing the expense of materials and hidden assets.

| Inventory | Make complete inventory Cycle inventory |

| Cycle Count | Location cycle inventory Commodity cycle inventory Customer cycle inventory |

| Reduce inventory lockdown measures | Small-grained multi-frequency inventory, location inventory mainly Virtual location hedges – Inventory adjustment |

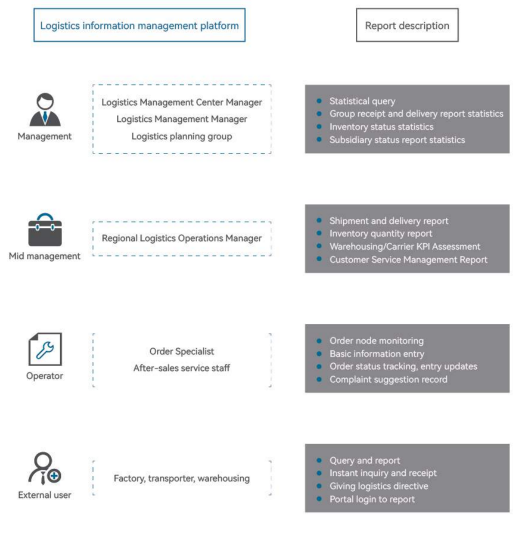

Warehouse Management System – Reporting System

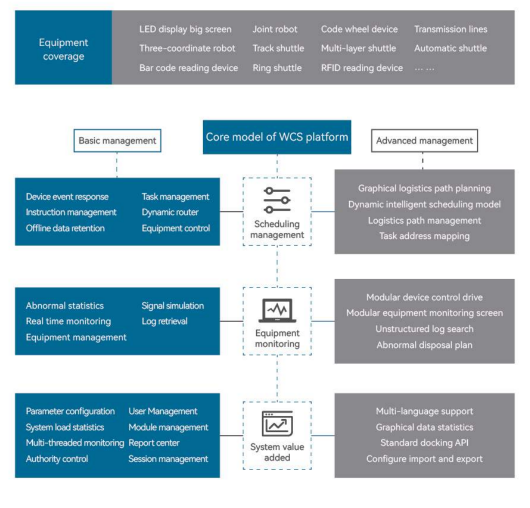

Warehouse Control System

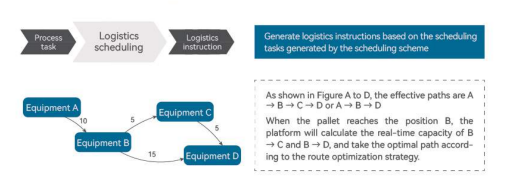

WCS is a device management system for scheduling management and control of all automation devices in smart storage. After receiving the command, the WCS automatically generates a scheduling plan and sends execution instructions to the relevant devices step by step until the task is completed. It can also monitor and display the status and location of all devices in real time and alert for abnormal information.

WCS Scheduling Plan

- After all the devices are registered, it is able to calculate the capacity among the device based on the actual situation.

- After all the physical capacity is gathered, the platform calculates all the access paths.

- When the pallet reaches the bifurcation, the capacity of the path is obtained, and the optimal path is calculated in real time according to the configured path strategy to complete dynamic routing scheduling.