In the dynamic realm of warehouse automation, SmartlogitecX turntables, a significant automated conveyor system, play a crucial role in facilitating the smooth transfer and rotation of goods, enhancing productivity, and streamlining material flow. These versatile systems seamlessly integrate with various warehouse operations, enabling the precise movement of items between conveyor lines, accumulation zones, and workstations. Turntables are widely employed in various industries, including retail, manufacturing, and logistics, to optimise material handling processes and improve overall efficiency.

Key Features and Advantages of Turntables

Turntables offer a range of advantages that make them a compelling choice for warehouse automation.

Efficient Material Transfer

Turntables enable the seamless transfer of items between conveyor lines, accumulation zones, and workstations, eliminating the need for manual lifting and carrying, reducing labor costs, and improving operational efficiency.

Flexible Rotation and Positioning

Turntables provide precise rotation capabilities, allowing items to be positioned at desired angles for efficient picking, packing, and inspection tasks.

Space Optimisation

Turntables can be installed in tight spaces, maximising valuable warehouse floor space while ensuring efficient material flow.

Adaptability to Various Applications

Turntables can accommodate a wide range of item sizes, shapes, and weights, making them adaptable to various material handling applications.

Durability and Low Maintenance

Turntables are designed for durability and require minimal maintenance, ensuring long-lasting operation and reducing downtime.

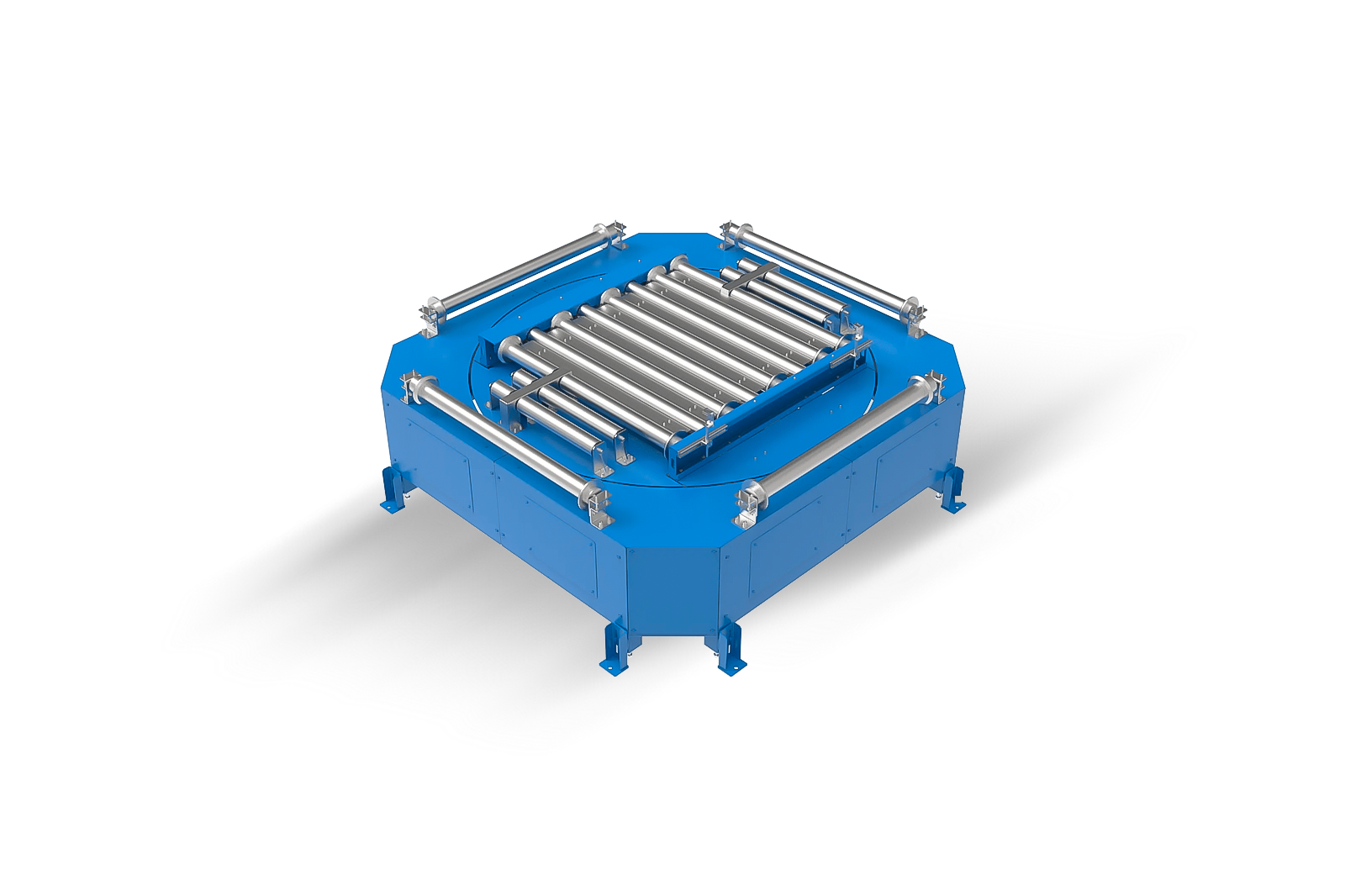

Components of a Turntable

A turntable typically consists of the following components:

Rotating Platform:

The rotating platform forms the main surface for item placement and rotation. It is constructed with durable materials to withstand regular use and heavy loads.

Drive System:

The drive system, such as an electric motor or hydraulic drive, provides the power for rotation. It is controlled by a sophisticated control system to ensure precise and controlled movement.

Sensors and Control Systems:

Sensors detect the presence and position of items on the turntable, while control systems orchestrate the rotation process and ensure accurate positioning.

Safety Features:

Turntables incorporate safety features, such as emergency stop buttons and safety guards, to prevent accidents and injuries.

Schedule a Call with SmartLogitecX

Applications and Use Cases of Turntables

Turntables are widely used in various industries and applications, including:

Retail Warehouses

Turntables are extensively employed in retail warehouses to facilitate the picking, packing, and inspection of items. They enable efficient movement of goods between picking lines, packing stations, and quality control areas.

Manufacturing Facilities

Turntables play a crucial role in manufacturing facilities by enabling the rotation and positioning of components, parts, and finished goods within production lines and assembly stations. They streamline production processes and enhance overall efficiency.

Logistics and Distribution Centres

Turntables are essential in logistics and distribution centres for transferring goods between conveyor lines, sorting areas, and shipping docks. They optimize material flow and expedite order fulfillment.

Postal and Courier Services

Turntables are utilised in postal and courier services to rotate and position packages for sorting, labeling, and shipping. They streamline sorting processes and improve delivery times.

Future Trends in Turntable Technology

The future of turntable technology is poised for significant advancements, driven by the demand for increased automation, efficiency, and flexibility in warehouse operations.

Key trends include:

Integration with Warehouse Management Systems (WMS)

Turntables will become more tightly integrated with WMS, enabling real-time data exchange, order fulfillment optimisation, and predictive maintenance capabilities.

Enhanced Robotics and Automation

Turntables will incorporate advanced robotics and automation technologies to further improve rotation precision, speed, and adaptability to changing item sizes and configurations.

Data Analytics and Predictive Maintenance

Turntables will leverage data analytics and machine learning to predict maintenance needs, optimise turntable performance, and prevent downtime, ensuring continuous operation and optimal system utilisation.

Turntables represent a valuable tool in the modern warehouse and distribution centre, streamlining material handling operations, enhancing productivity, and reducing labor costs. As technology advances, turntables will become even more sophisticated and efficient, further revolutionising the way goods are moved and processed throughout the supply chain.

Discover the future of Warehouse Automation with SmartlogitecX, brought to you by the technological prowess of WayZim Technologies. We’re leading a logistics revolution in Australia and New Zealand. Choose SmartlogitecX for a blend of local insight and global innovation. Transform your warehouse operations with our specialised technology. Interested in advancing your logistics? Contact our SmartlogitecX sales team for a solution tailored to your needs.