Automated warehouses are becoming increasingly common in Australia as businesses look to improve efficiency and reduce costs. An automated warehouse utilises various technologies such as robotics, automated storage and retrieval systems (ASRS), conveyor systems, and warehouse management software to automate warehouse processes.

What are the Benefits of Automated Warehouses?

There are several key benefits that automated warehouses offer compared to traditional manual warehouses:

- Improved accuracy and reduced errors

Automated systems are designed to repeatedly perform tasks in the exact same way, eliminating many of the errors associated with manual processes. This improves inventory accuracy and order fulfillment. - Increased productivity

Automated systems can work around the clock without breaks, increasing throughput and workflow. This allows businesses to fulfill more orders with less staff. - Reduced labor costs

By reducing the need for manual labor, automated warehouses require less staffing for many tasks. This significantly lowers labor costs. - Enhanced scalability

Automated systems allow warehouses to easily scale operations up or down to meet changing demand. Additional storage, robots, or conveyors can be added as needed. - Better inventory control

Automated warehouses utilise warehouse management systems that provide real-time inventory tracking and coordination. This improves visibility and control over stock. - Improved space utilisation

Automated storage and retrieval systems can store inventory in tighter configurations, maximising storage density. This allows more inventory to fit into a smaller footprint. - A safer work environment

Automating dangerous or repetitive tasks leads to fewer workplace injuries and incidents. Work becomes more ergonomic.

Types of Automated Warehouse Technologies

There are a variety of technologies that enable warehouse automation, including:

Automated storage and retrieval systems (ASRS)

Computer-controlled systems that automatically place and retrieve loads from defined storage locations. High-density storage is enabled.

Automated guided vehicles (AGVs)

Driverless vehicles that follow guidance systems on the warehouse floor transport materials. Often used for horizontal transport between workstations.

Robotic pickers

Robots equipped with suction cups, grippers, or other technology can pick items from shelves and convey them to the next stage of operations.

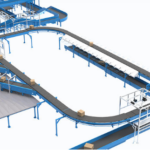

Conveyor systems

Motorised conveyors that move materials between processes, reducing manual material handling.

Warehouse management system (WMS)

Software that tracks inventory and coordinates automated warehouse processes for optimised workflow.

Warehouse execution system (WES)

Software that controls automated systems and equipment on the warehouse floor to execute optimised tasks.

Warehouse control system (WCS)

Low-level software that directly interfaces automated components to instruct physical movements and processes.

Which Australian Companies are using Automated Warehouses?

Many large Australian retailers and logistics companies are turning to automation to drive efficiency in their warehouses and fulfillment centres, including:

Coles

Coles has heavily invested in automated fulfillment centres that utilise robotic pickers and automated storage systems. Their state-of-the-art facilities in Queensland and NSW service online orders.

Woolworths

Woolworths is rolling out robotic warehouses across Australia, including a $215 million semi-automated distribution centre in Melbourne. Automation provides significant boosts in productivity.

Australia Post

Major sorting and fulfillment centres for Australia Post leverage conveyor systems, automated storage units, and address reading technology for faster processing.

Toll Group

Toll Group operates over 40 automated and semi-automated warehouses, supporting customers across industries. Technologies include pick-to-light, put-to-light, and voice guidance.

Linfox

This third-party logistics company provides customised automated warehouse solutions for customers. Technologies include automated guided vehicles, automated cranes, and integrated warehouse control.

DB Schenker

Schenker’s logistics sites feature advanced automated warehouses with automated storage and retrieval systems, speeding order processing.

The Future of Automation in Warehouses

Experts forecast strong, continued growth in spending on warehouse automation in Australia. As the technology matures and costs decline, more small and midsize operations will adopt automation. We are also likely to see an increasing deployment of robotics, machine learning, and AI to enable warehouses to become even smarter and more efficient. For any business with warehousing and distribution needs, it’s worth exploring how intelligent automation solutions could take their operations to the next level.

Join forces with SmartlogitecX, backed by the technological strength of WayZim Technologies, and lead the charge in Warehouse Automation in Australia and New Zealand. We are more than a service; we are your strategic partner in redefining logistics. Opt for SmartlogitecX to harness the full potential of advanced technology, crafted with an understanding of the local market. Connect with our sales team to begin your journey towards an automated, efficient future.

FAQ

1. What are the main benefits of automated warehouses?

The main benefits of automated warehouses include improved accuracy, increased throughput and productivity, lower labor costs, better inventory control and space utilisation, and an enhanced safety environment.

2. How can automated technologies improve warehouse inventory management?

Automated warehousing technologies, like warehouse management systems, provide real-time inventory tracking across all systems. This gives complete visibility and coordination of stock, leading to improved inventory control.

3. What types of warehouses are best suited for automation?

Large warehouses with significant order volumes, frequent repeatable processes, and extensive inventory benefit the most from automation. High-density storage environments are also prime candidates for automated storage and retrieval systems.

4. What are some key automated technologies used in warehouses?

Top automated technologies include automated storage and retrieval systems (ASRS), automated guided vehicles (AGVs), robotic pickers, conveyors, warehouse management systems (WMS), warehouse execution systems (WES), and warehouse control systems (WCS).

5. What skills are needed to work in an automated warehouse?

Working in an automated warehouse requires skills like using warehouse management and execution systems, basic robotics operation and maintenance, analytical and problem-solving abilities, comfort learning new technologies, and attention to detail.