Introduction

The Pallet Four-way Shuttle is an intelligent handling device that can travel both longitudinally and horizontally. It is capable of in-situ track shifts, automated handling, intelligent monitoring and traffic dynamics management. With high flexibility, it is best used to handle goods on high-density shelves. It can move in between shelves and be adjusted flexibly. With capabilities like four-way movement, instant track switching, automated transport, and intelligent monitoring, this shuttle enables both horizontal and vertical movement within shelving, achieving maximum storage density when paired with lifts.

Key Specifications:

1.Direction Change Time: 2-4 seconds

2.Full-Load Speed: 1.2 m/s

3.Rated Load: 1500 kg

4.Positioning Accuracy: ±2 mm

Designed for high-volume, single-category industries—such as food, beverages, chemicals, and tobacco—our shuttle system boosts warehouse efficiency and streamlines distribution.

Key Technologies of Pallet Four-way Shuttle.

1. Travel Positioning Technology:

Servo-controlled positioning

Precise laser sensor positioning

Storage location confirmation through barcode scanning/RFID (RFID is recommended for cold storage)

Photoelectric sensors for pallet identification

2. Safety Technology:

Automatic obstacle detection by using six radars, identifying obstacles and stopping immediately

Automatic detection of goods in the target storage location

Multi-shuttle avoidance technology

3. Power Battery Technology:

Lithium iron phosphate battery

Intelligent power supply control

Ambient temperature: –25 ℃ to 45 ℃

Power supply: 48 V, 40 Ah, charging for 1 to 2 h, and working for 7 to 8 h

4. Automatic Charging Technology:

Real-time monitoring of the battery

Automatically moving to the charging area for charging when the battery capacity is lower than the minimum battery level

Six-sided fireproof charging pile

Key Safety Configuration.

1.Six Safety Radars: Monitor main and sub-tracks for stable operation.

2.Emergency Stop & Charging: Quick response and recharge capabilities.

3.Anti-collision Blocks: Physical safeguards against collisions.

4.LED Strip Lights: Enhance visibility for safe navigation.

Fault Recovery Mechanism of Pallet Four-way Shuttle.

In general, there are two scenarios, as shown below.

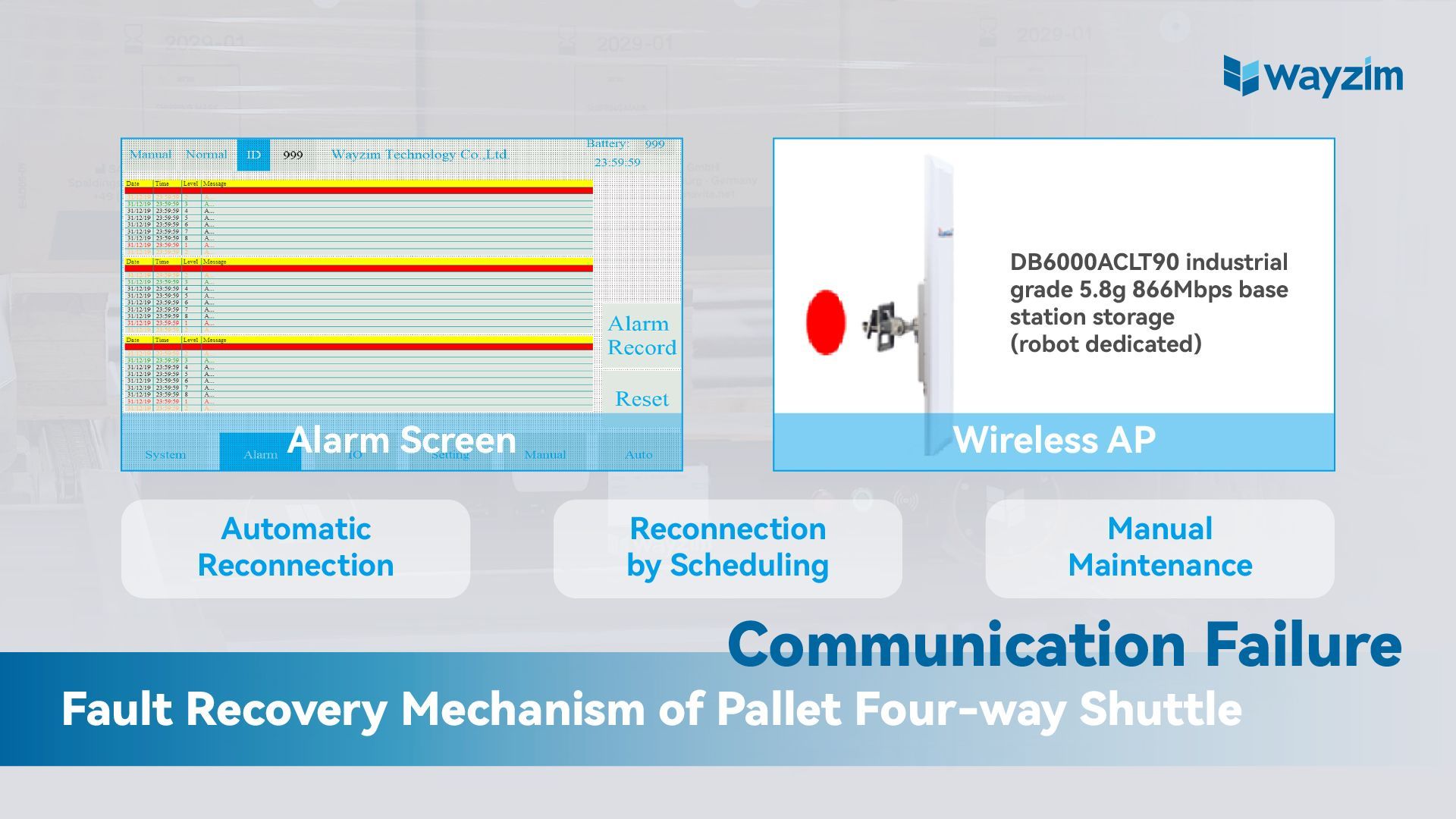

When Communication Failure:

Automatic Reconnection: Our Pallet Four-way Shuttle automatically attempts to reestablish communication in case of failures, ensuring minimal disruption to operations.

Manual Reconnection and Maintenance: For instances requiring manual intervention, our system allows for reconnection through the scheduling system and manual restarts using a remote terminal tablet.

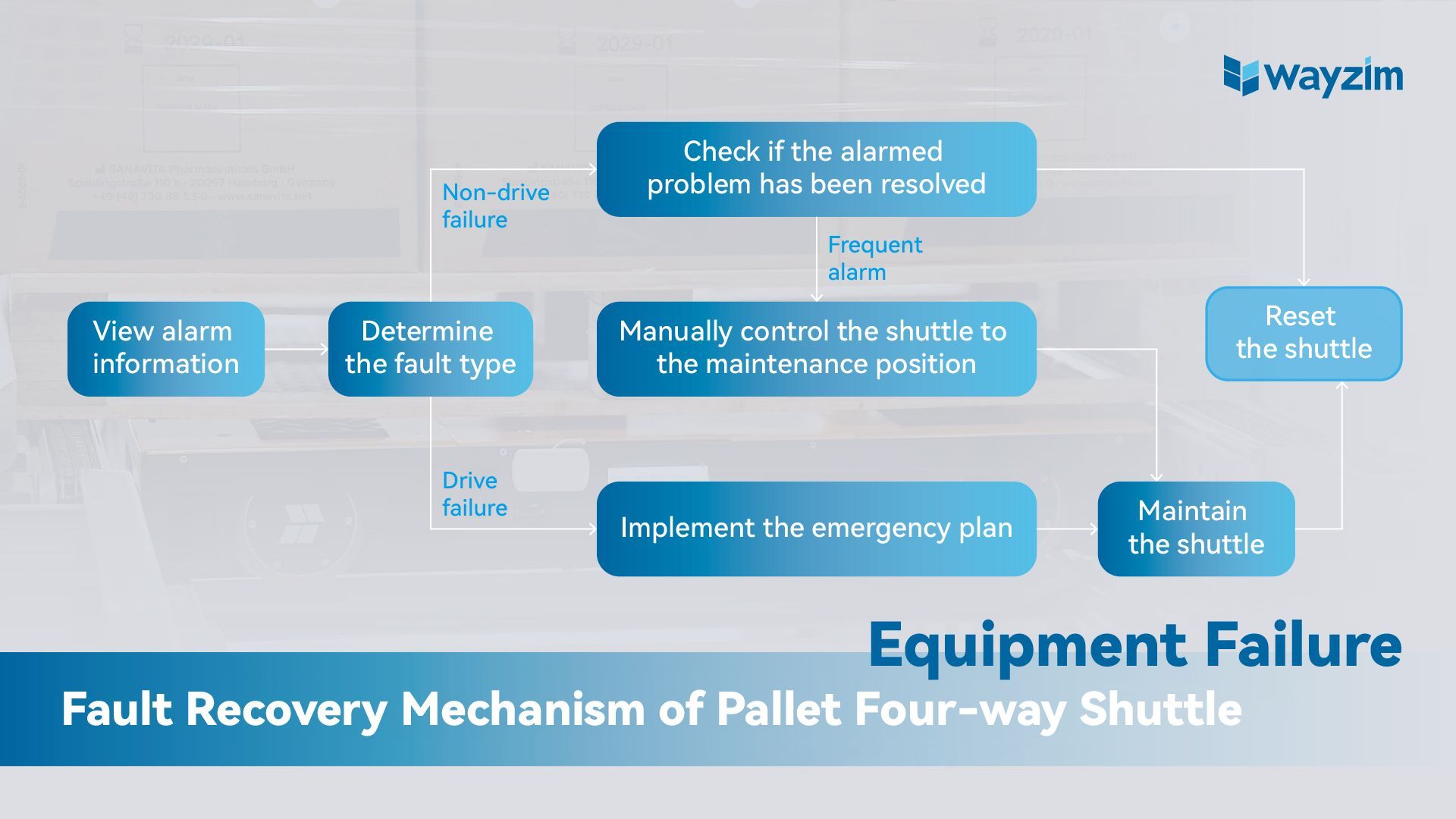

When Equipment Failure:

Fault Identification and Emergency Protocols: Upon an alarm, our system quickly identifies the fault type (non-drive or drive failure) and implements emergency plans to control the shuttle to the maintenance position.

Maintenance and Reset: Frequent alarms trigger maintenance protocols to address recurring issues. Once resolved, the shuttle can be reset and returned to operation.

Pallet Four-Way Shuttle in Medical Logistics.

Pallet Four-Way Shuttle is powering the transformation of a major East China medical device warehouse, bringing high flexibility, accuracy, and safety to a challenging environment. The system supports multi-directional movement with ≤ ±2 mm positioning accuracy, allowing instant direction changes.

In this space-sensitive project, we implemented a 125 pure mechanical shuttle, achieving low-profile storage just 300 mm from the ground while maintaining stringent cleanliness.

Key highlights:

1.3DMS Digital Twin System for real-time operational monitoring, with fast troubleshooting.

2.Fireproof charging piles with protective wall enclosures, containing potential fires on all six sides.

3. Storage capabilities: 3,000+ pallet positions, storing 50,000+ boxes, with throughput reaching 60 pallets/hour.

This solution directly addresses the client’s key challenges: rising business volumes, limited warehouse space, increasing SKUs, high-speed order requirements, and accuracy issues with manual picking. Wayzim’s automated system ensures high efficiency, minimised errors, and secure, scalable storage.