Introduction

In this article, we will explore the Narrow Belt Sorter, a cutting-edge solution designed for efficient and versatile parcel handling in modern logistics environments. We’ll dive into its innovative design, key components, and the unique advantages it offers over traditional sorting systems. From its ability to handle a wide range of parcel types and sizes to its low operating noise and space-efficient configuration, the Narrow Belt Sorter presents a compelling option for facilities seeking to enhance their sorting capabilities. Join us as we examine how this technology can optimise your operations and deliver exceptional performance.

Narrow Belt Sorter

The Narrow Belt Sorter is an advanced line sorting system designed for efficient parcel handling. It features bi-directional rotating carriers, which serve as both the load and sorting units. These carriers are strategically arranged on a dedicated main drive line that continuously circulates, ensuring accurate and timely sorting of parcels.

The system’s vertical circulating layout and compact structure are key design elements that set it apart. The reduced pitch between sorting carriers allow for the simultaneous sorting of both large and small parcels, offering a greater flexibility compared to traditional systems. This means that parcel sizes are not confined to a narrow range; instead, the sorter can accommodate a wide variety of parcel types and sizes simultaneously, enhancing overall operational efficiency.

The mechanical design of the sorter can be customised to meet the specific requirements of the application and site layout. This includes adjusting the length of the conveyor track, the number of carriers, barcode readers, and unloading outlets. The conveyor track is designed as a straight line, with its total length tailored to fit the layout of each facility. The number of carriers is determined by the length of the conveyor track, while the unloading outlets are strategically placed on both sides of the track in alternating directions. The width and number of unloading outlets are configured based on parcel sizes and operational needs.

Throughput and Suitable product types

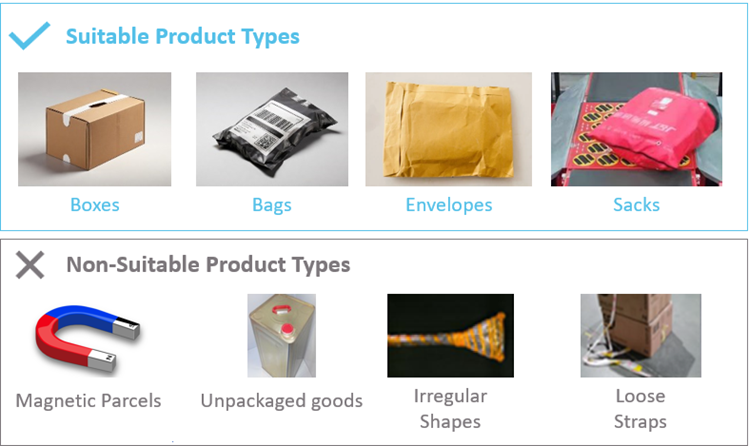

The Narrow Belt Sorter’s innovative narrow carrier design allows it to transport a wide variety of parcel types and sizes simultaneously, making it a highly versatile sorting solution.

The sorter can efficiently handle parcels as small as 150 x 150 x 30 mm (L x W x H) and as large as 1,300 x 1,100 x 1,100 (L x W x H), accommodating product weights ranging from as light as 0.2kg to as heavy as 60kg. This broad capacity makes it suitable for sorting not just cartons, but also bags, envelopes, sacks and many other product types.

With a maximum throughput of 9,000 parcels per hour (PPH), the Narrow Belt Sorter delivers high performance in diverse operational settings. Its ability to manage such a wide range of product types and sizes makes it extremely adaptable to various sorting scenarios, whether in e-commerce fulfilment centres, distribution warehouses, or logistics hubs. The flexibility and efficiency of this sorter make it an invaluable asset in environments where the ability to quickly and accurately sort a diverse array of parcels is critical.

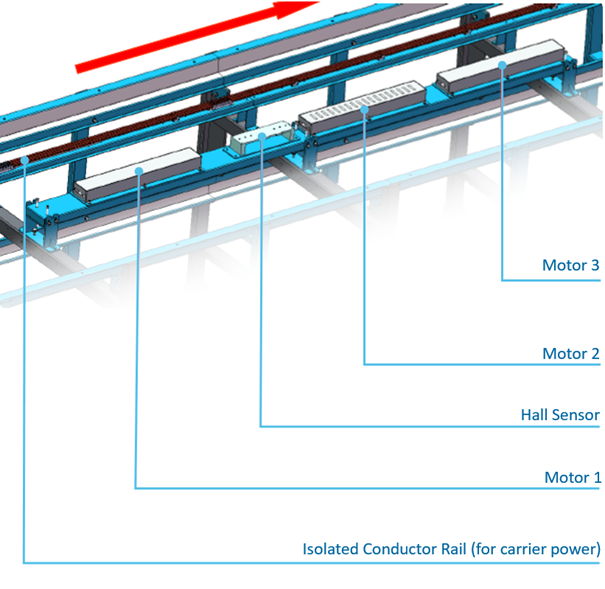

Main Drive

The primary drive mechanism of the Narrow Belt Sorter is a permanent magnet linear motor, which is integrated with Hall sensors to precisely control the speed and movement of the main sorting line. This advanced combination ensures that the system operates with high efficiency, accuracy, and reliability, making it a superior choice for modern parcel sorting needs.

The integration of Hall sensors with the permanent magnet linear motor allows for real-time feedback and adjustment of the sorter’s speed and movement. This precise control not only enhances the overall performance of the sorter but also contributes to smoother and more consistent operation, reducing the likelihood of errors or delays in the sorting process.

One of the key benefits of utilising a permanent magnet linear motor is its high efficiency, which results in lower energy consumption and operational costs. Additionally, the motor’s design with fewer moving parts significantly reduces the need for maintenance, leading to increased uptime and lower maintenance expenses.

The linear motor also contributes to a quieter working environment, with noise levels at the head and tail of the equipment kept at or below 75dB(A), and at or below 70dB(A) in the mid-section. This quiet operation is particularly advantageous in facilities where noise reduction is a priority.

Overall, the use of a permanent magnet linear motor in the Narrow Belt Sorter provides numerous operational benefits, including improved precision, efficiency, and durability, while also offering a quieter and more reliable sorting solution.

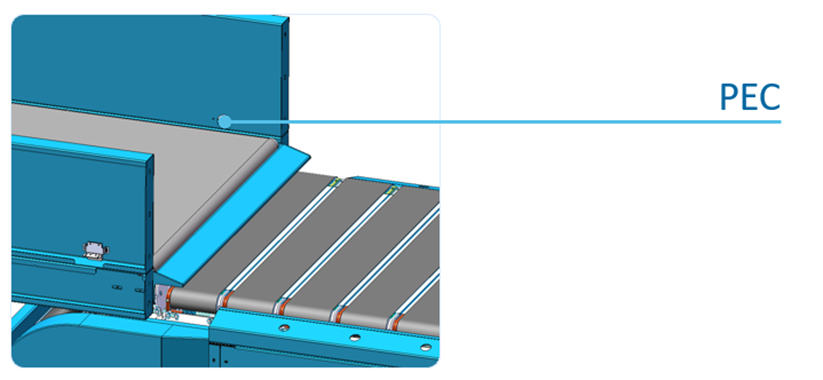

Parcel Induct onto Sorter (Top Loading)

Parcels are inducted onto the Narrow Belt Sorter through a top-loading mechanism, where a conveyor positioned slightly above the sorter gently deposits parcels onto the moving carriers. This top-loading design offers an efficient and space-saving method for inducting parcels onto the sorter while ensuring gentle handling to prevent damage.

Top-loading is particularly advantageous for its ease of use and compact design, making it an ideal solution for facilities with limited space. Additionally, the gentle handling provided by this method minimises the risk of parcel damage during the loading process, further enhancing the reliability of the sorting system.

For even greater efficiency, an optional Volume Scanner can be installed at the induction point. This scanner determines the exact position of the parcel along the width of the conveyor, and this data is relayed to the Narrow Belt Sorter, By providing precise information about the parcel’s dimensions and orientation, the system can achieve more accurate and efficient transfer to its final destination, further improving the overall sorting performance.

In summary, the top-loading mechanism, enhanced by advanced sensing technology, provides a streamlined and reliable method for parcel induction, ensuring smooth and accurate sorting with minimal space requirements. The addition of a Volume Scanner can further optimise the process, making the Narrow Belt Sorter an exceptionally efficient solution for a wide range of parcel types and sizes.

Carrier Design

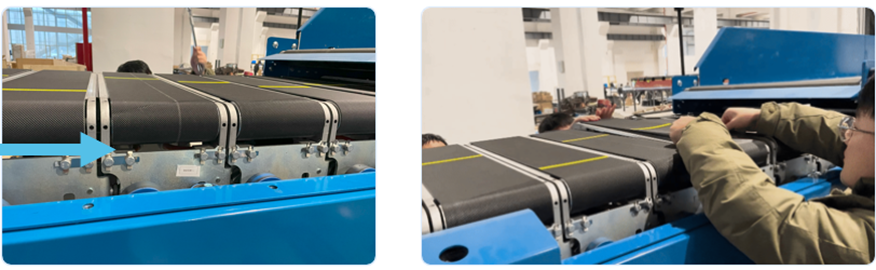

The carrier serves as the core component of the system, functioning as an independent module responsible for transporting parcels to their designated outlets. During the unloading process, the carrier’s belt rotates to smoothly transfer parcels from the carrier to the specified outlet.

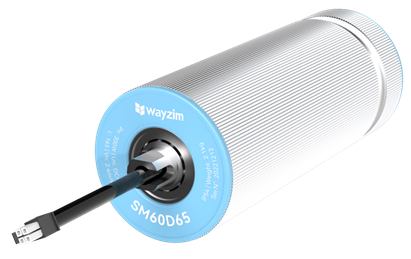

The carrier design of the Narrow Belt Sorter is both efficient and straightforward, centered around a 48V drum motor that serves as the primary driving force for the belt. This 48V drum motor, specifically the SM60 model, is manufactured in-house at Wayzim. It is rated at 300W and is capable of producing up to 4 N.m of toque, providing the necessary power for reliable parcel transportation.

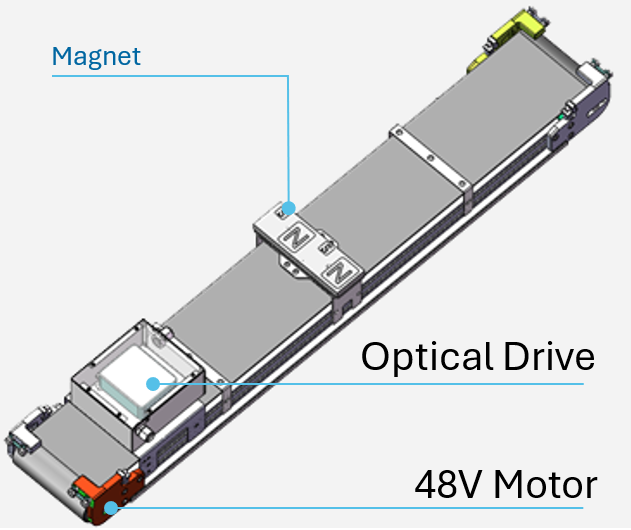

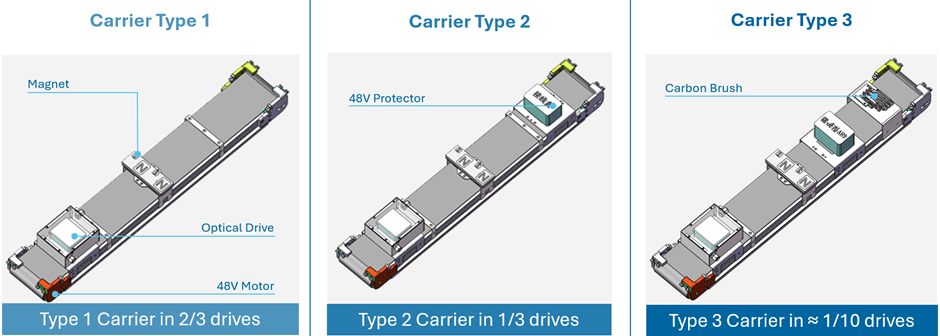

Each carrier is equipped with its own motor, which is connected to a motor driver mounted directly on the carrier. This motor driver includes a built-in infrared receiver, allowing it to receive and execute sorting instructions transmitted via infrared communication. Additionally, a permanent magnet is mounted on each carrier, serving as part of the moving element in the permanent magnet linear motor system. The electromagnetic coils, which are the stationary components of the motor, are mounted on the carrier frame, ensuring smooth and efficient operation.

To manage power distribution effectively, the system employs a clever design where one in every three carriers, known as Type 2 carrier, is equipped with a 48V power distribution unit. This unit not only powers its own carrier but also distributes power to the two adjacent carriers, optimising the electrical layout.

Furthermore, approximately one in every ten carriers (type 3 carrier) is equipped with a carbon brush. This carbon brush plays a critical role by collecting power from an isolated conductor rail that runs along the length of the sorter. The collected power is then distributed to the other carriers, ensuring a consistent and reliable power supply throughout the system.

This integrated design, featuring in-house manufactured components and efficient power distribution, enhances the reliability and performance of the Narrow Belt Sorter, making it a robust solution for high-demand sorting environments.

Faster Discharge

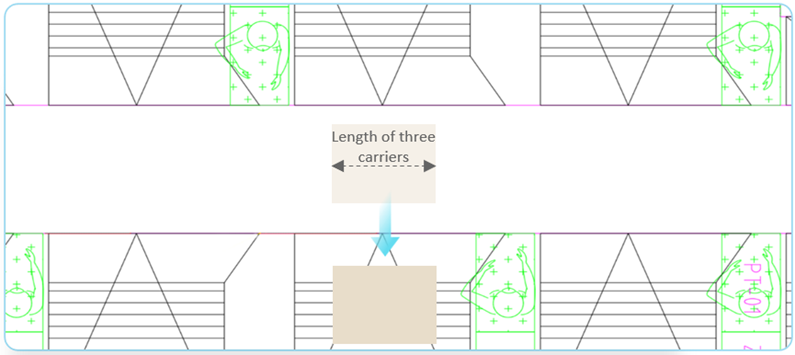

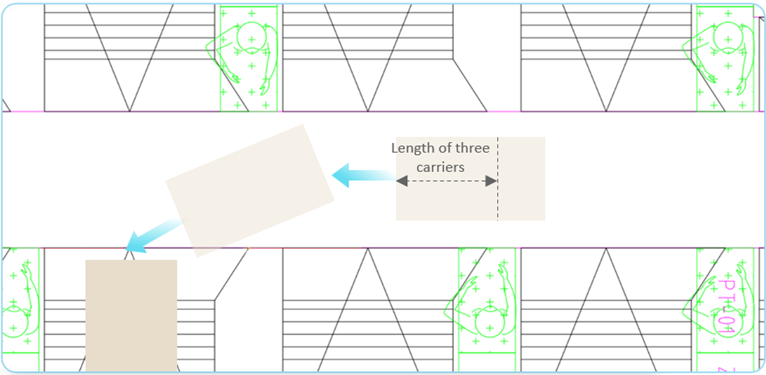

The Narrow Belt Sorter employs two distinct methods for parcel discharge, tailored to the size of the parcel to ensure efficient and accurate sorting.

For parcels that do not exceed the length of three carriers, all the carriers holding the parcel discharge simultaneously as a group. This synchronised release diverts the parcel at a 90-degree angle relative to the chutes, ensuring smooth and precise transfer.

For larger parcels that exceed the length of three carriers, the system utilises a sequential discharge method. In this case, the carriers are driven one after the other, allowing the long parcel to be discharged at an angle into the chute. This angled release is designed to prevent potential snagging or jamming, ensuring that larger parcels are sorted efficiently and without error.

By utilising these two discharge methods, the system is capable of handling a wide range of parcel sizes with optimal accuracy and speed, reducing the likelihood of sorting errors and increasing overall operational efficiency.

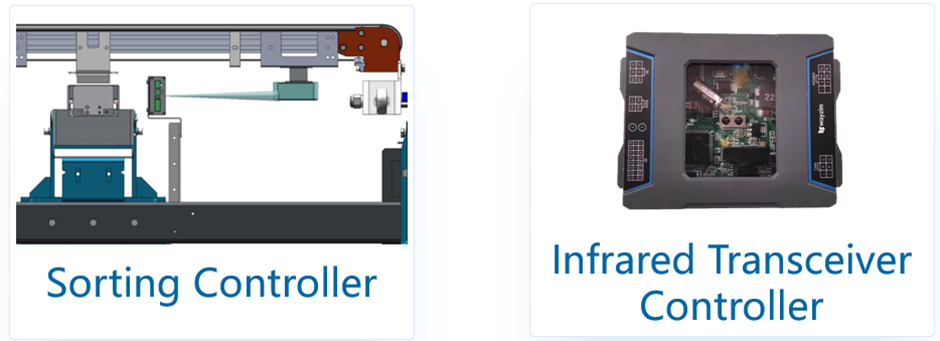

Communication with Carriers

Sorting instructions for the Narrow Belt Sorter are transmitted to each carrier using infrared communication technology. An infrared controller, mounted within the sorters frame, sends sorting signals to each carrier as it passes by. These signals are essential for diverting the parcels to their correct destinations.

Each carrier is equipped with an infrared receiver integrated into its motor driver unit. This receiver picks up the sorting signals sent by the controller, ensuring that each carrier receives the precise instructions needed for accurate parcel sorting. As a carrier approaches its destination, the motor driver unit activates the belt, smoothly transferring the parcel to the correct location.

This use of infrared communication provides several key benefits; it ensures reliable and interference-free transmission of sorting instructions, allows for real-time adjustments during operation, and contributes to the overall efficiency and accuracy of the sorting process. By employing this technology, the Narrow Belt Sorter is able to handle a high volume of parcels with precision, reducing sorting errors and improving throughput.

Maintenance

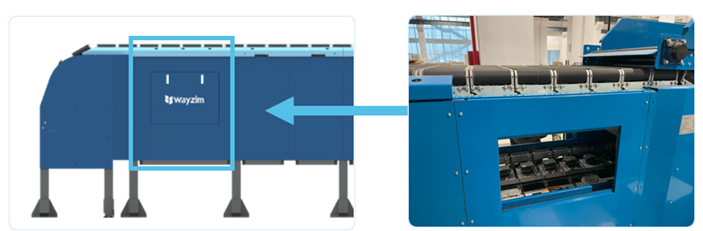

Simple and quick maintenance is one of the standout features of the Narrow Belt Sorter. The system is designed for fast carrier replacement within minutes, ensuring minimal downtime and maintaining operational efficiency. The replacement process involves the following straightforward steps:

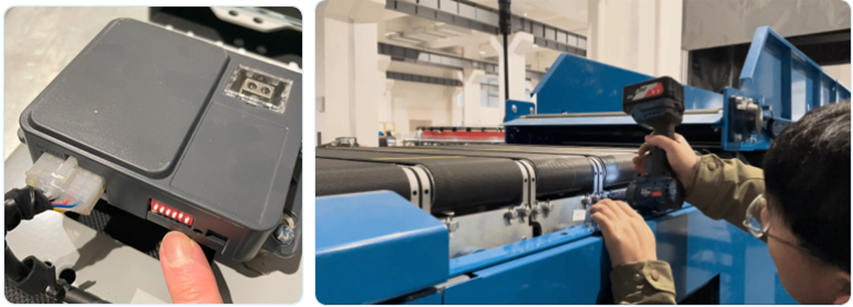

- Activate Maintenance Mode: Begin by activating the maintenance mode, which will automatically move the faulty carrier above one of the two maintenance hatches located at either end of the sorter.

2. Remove the Faulty Carrier: Loosen the eight bolts securing the carrier, disconnect the cable connections, and carefully lift the carrier to remove it from the system.

3. Prepare and Install the Replacement Carrier: Set the dip switch on the replacement carrier to match the settings of the faulty carrier. Install the spare carrier by plugging in the connectors and securing the eight carrier bolts.

4. Complete the Replacement: Once the new carrier is installed, the replacement process is complete. The faulty carrier can be repaired at a convenient time and stored as a spare for future use.

This streamlined maintenance procedure ensures that carrier replacement is both fast and efficient, minimising disruptions to the sorting process and maintaining high system availability.

Warranty

All of Wayzim’s Narrow Belt Sorters are accompanied by a comprehensive one-year warranty as standard, which encompasses the provision of replacement parts and associated installation services. This warranty ensures that any defective or malfunctioning components will be promptly addressed, thereby guaranteeing optimal performance and longevity of the equipment.

Manufacturing and Lead Times

Thanks to the extensive scale and advanced capabilities of Wayzim’s manufacturing facility in Anhui, we are able to produce Narrow Belt Sorters to the highest standards with remarkably short lead times. From the moment an order is placed, we can complete the manufacturing process and prepare the Narrow Belt Sorter for shipment within just six weeks.

Why Choose the Narrow Belt Sorter ? Here are some of the key benefits

- Versatile Parcel Handling: Accommodates a wide variety of parcel types and sizes simultaneously on a single sorter.

- Low Operating Noise: Designed for quiet operation, minimising noise pollution in the facility.

- High Reliability: Utilises purely electric components, eliminating the need for compressed air and reducing the potential for mechanical failures.

- Space-Efficient Design: Configurable to fit within most facility layouts, optimising available space.

- High Throughput: Capable of processing up to 9,000 parcels per hour (PPH), ensuring rapid and efficient sorting.

- Cost-Effective Maintenance: Engineered for ease of maintenance, reducing downtime and associated costs.

- Proven Performance: Backed by extensive field installations, demonstrating consistent and reliable operation.

- Cost-Effective Alternative: Offers a more economical solution compared to traditional shoe sorters.

- Rapid Delivery: Short lead time of just 6 weeks from order to manufacture and ready for shipping, enabling quick deployment.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the sales team for your customised automation solution.