The dawn of the industrial age introduced us to the concepts of mechanisation and automation, changing the landscape of manufacturing and distribution forever. Among these technological advancements, automated conveyor systems have emerged as a cornerstone of modern industry, revolutionising the way materials and goods are moved within manufacturing facilities, warehouses, and distribution centres. This article delves into the evolution, benefits, and critical aspects of automated conveyor systems, providing insights into how these systems enhance operational efficiency, safety, and productivity across various sectors.

The Backbone of Industrial Automation

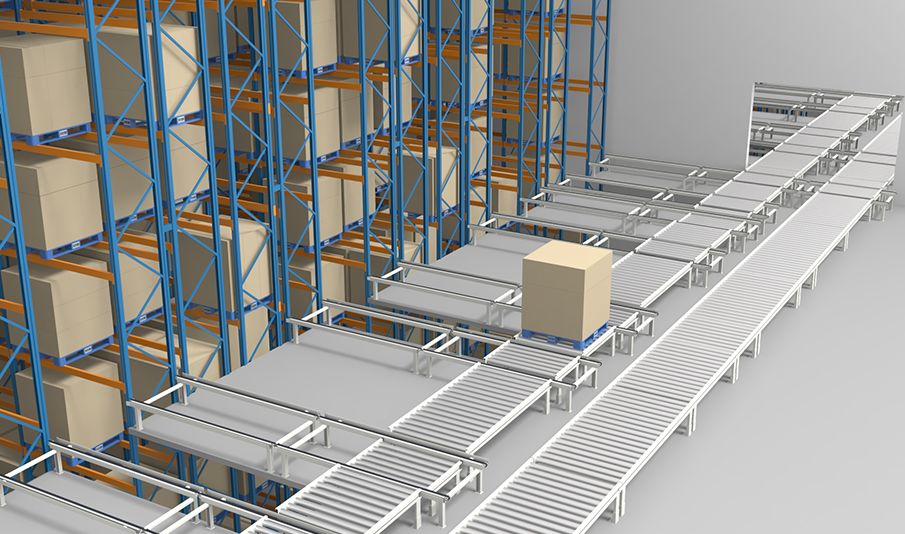

Automated conveyor systems, a pivotal component of material handling processes, facilitate the seamless movement of products and materials from one point to another within a confined space. These systems are designed to minimise manual handling, thereby reducing labor costs and enhancing safety. They vary widely in design, from belt conveyors to roller systems, and cater to diverse industries including manufacturing, retail, food and beverage, and pharmaceuticals. Specifically, within the realm of warehouse automation, these systems play a critical role in optimising the flow of goods, ensuring that items are stored, retrieved, and transported with unprecedented efficiency.

Enhancing Efficiency and Productivity

One of the primary advantages of automated conveyor systems is their ability to significantly boost efficiency and productivity. By automating the movement of materials, businesses can ensure a continuous flow of operations, minimising downtime and eliminating bottlenecks. This continuous flow allows for faster processing times, increasing the overall output of a facility. The integration of automated sortation systems within conveyor setups further enhances this efficiency, accurately sorting products at high speeds to significantly improve order fulfillment rates and accuracy.

RELATED: Exploring the Efficiency of Automatic Conveyor Systems

Safety and Ergonomics

Safety is paramount in any industrial setting. Automated conveyor systems reduce the need for manual lifting and carrying, thereby minimising the risk of workplace injuries. This not only protects employees but also reduces the potential for costly downtime and compensation claims. Furthermore, ergonomic design principles can be integrated into conveyor systems, making operations safer and more comfortable for workers.

Scalability and Flexibility

Scalability and flexibility are crucial features of modern automated conveyor systems. As businesses grow and their operations evolve, conveyor systems can be adapted and expanded to meet changing needs. This adaptability ensures that investments in conveyor technology remain viable in the long term, supporting business growth and diversification.

Sustainability and Environmental Impact

In today’s eco-conscious world, sustainability is a significant concern for businesses across all sectors. Automated conveyor systems contribute to greener operations by optimising energy use and reducing waste. Efficient material handling processes mean less energy consumption and lower carbon footprints, aligning with the global push towards environmental sustainability.

RELATED: Automated Conveyor Systems: Revolutionising Industrial Efficiency

FAQs on Automated Conveyor Systems

- What are the main types of automated conveyor systems?

Automated conveyor systems come in various forms, including belt conveyors, roller conveyors, and overhead conveyors, each designed to meet specific operational needs and material handling requirements. - How do automated conveyor systems improve workplace safety?

By reducing the need for manual handling, automated conveyor systems minimise the risk of injuries associated with lifting and moving heavy materials. This leads to a safer working environment and can help reduce the incidence of musculoskeletal disorders. - Can automated conveyor systems be customised for specific industry needs?

Yes, automated conveyor systems can be highly customised to fit the unique needs of different industries. Whether it’s adjusting the speed, the material of the conveyor belt, or integrating with other automated systems, customisation ensures that the conveyor system enhances operational efficiency. - What is the impact of automated conveyor systems on operational costs?

Automated conveyor systems can significantly reduce operational costs by minimising manual labor, reducing waste, and increasing the efficiency of material handling processes. The initial investment is often offset by the long-term savings in labor and enhanced productivity.

By integrating automated conveyor systems into their operations, businesses can achieve significant gains in efficiency, safety, and productivity. These systems are not just a testament to human ingenuity but a vital component of modern industrial operations, driving progress and innovation across sectors. As technology continues to evolve, so too will the capabilities and applications of automated conveyor systems, further solidifying their role in the industrial landscape.

Discover the future of Warehouse Automation with SmartlogitecX, brought to you by the technological prowess of WayZim Technologies. We’re leading a logistics revolution in Australia and New Zealand. Choose SmartlogitecX for a blend of local insight and global innovation.

Transform your warehouse operations with our specialised technology. Interested in advancing your logistics? Contact our SmartlogitecX sales team for a solution tailored to your needs