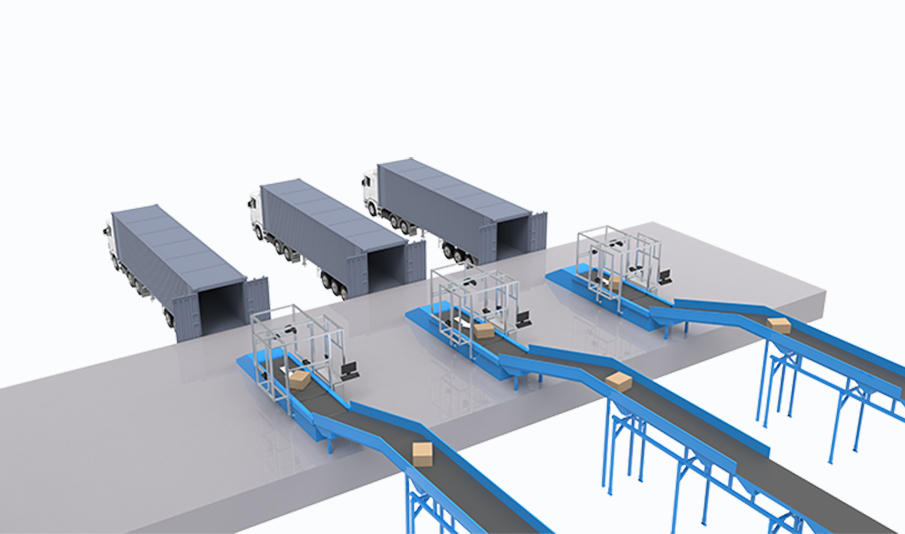

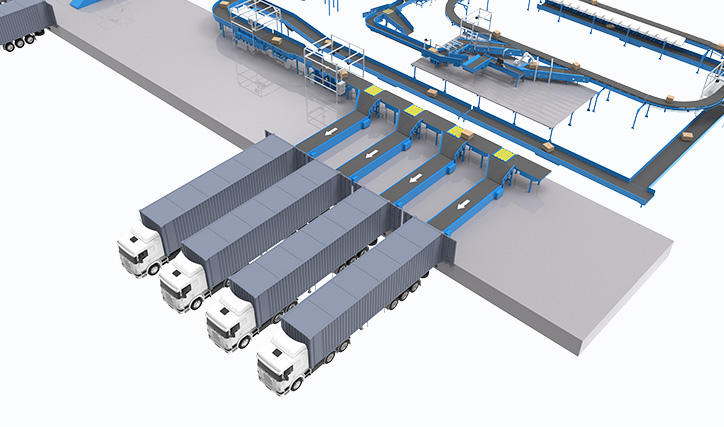

Solution for Large Parcel Unloading Area

It is composed of telescoping belt conveyors, high-speed belt conveyors, 2D bulk flow singulators, DWS detection equipment, RFID identification equipment, and sorting execution modules. With an improved control system, the solution achieves automated sorting of parcels from unloading to loading.

Multi-carrier collaboration

Multi-carrier collaboration to flexibly meet peak sorting demands and challenges with sorting efficiencies up to 6000 pcs/h

Modular design

Lightweight design and modular thinking can be dynamically optimized according to the site and cargo type.

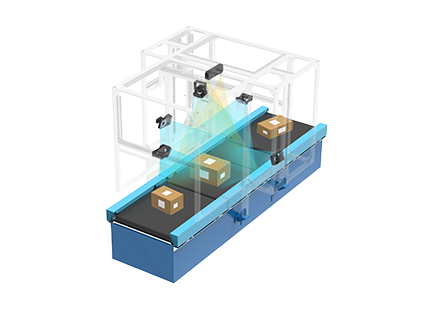

Accurate sorting

Singulator controls spacing, six-sided scan camera makes all-around detection and the parcel trajectory is traced in real time, with accuracy rate more than 99%.

Standard flow

Automated logistics equipment combined with advanced IoT technology is used to build a standardized automated sorting system.

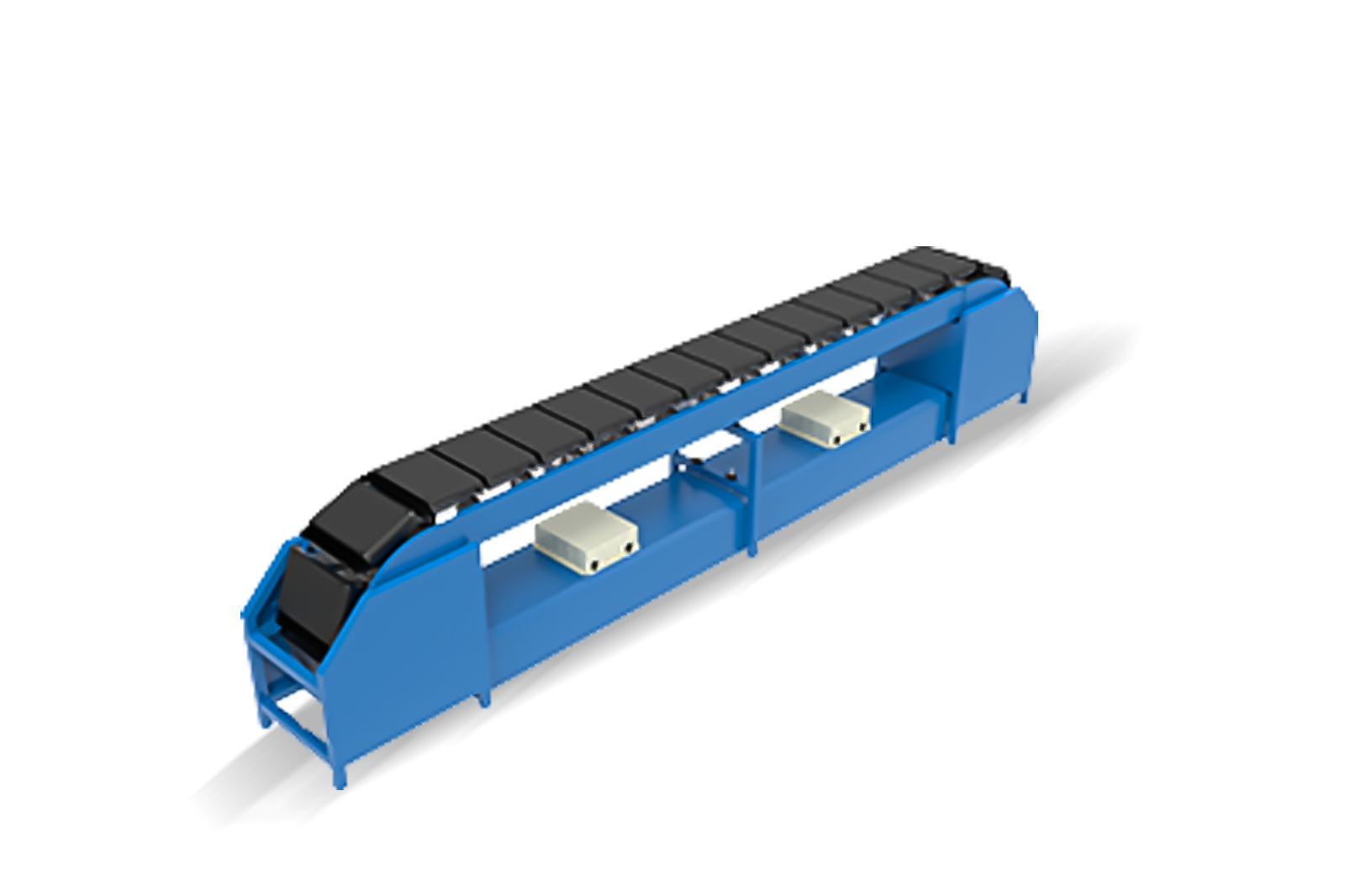

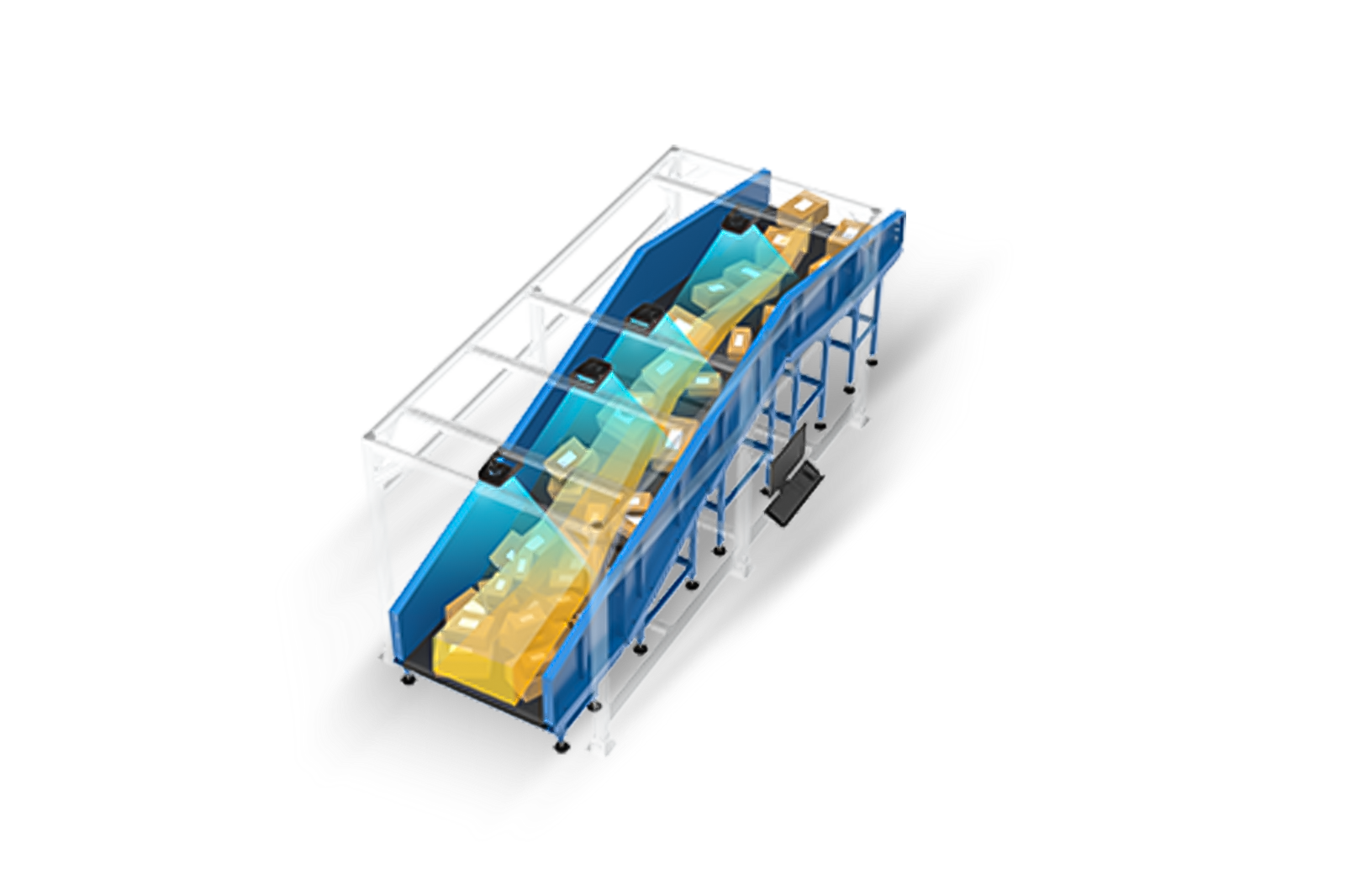

Solution for Large Parcel Loading Area

It is composed of troughed belt conveyors, automated baggage storage and retrieval belt conveyors, 2D singulation modules, centering modules, gapping belt conveyors, 6-sided scanning camera modules, RFID electronic channel doors, pivot wheel modules, outlet chutes, and telescoping conveyors.

Low hardware costs

Good cost control can be achieved with standard equipment control of IoT and PLC.

High sorting efficiency

Maximize the conveyor line capacity by matching parcel size options and individual machines.

Flexible sorting

In the sorting process, there is no mechanical tapping or other forceful sorting behavior to avoid parcel damage to the maximum extent.

Unmanned factory

The sorting center basically realizes unmanned sorting operation, and combined with the site unloading system, it can realize the whole-process parcel tracking.

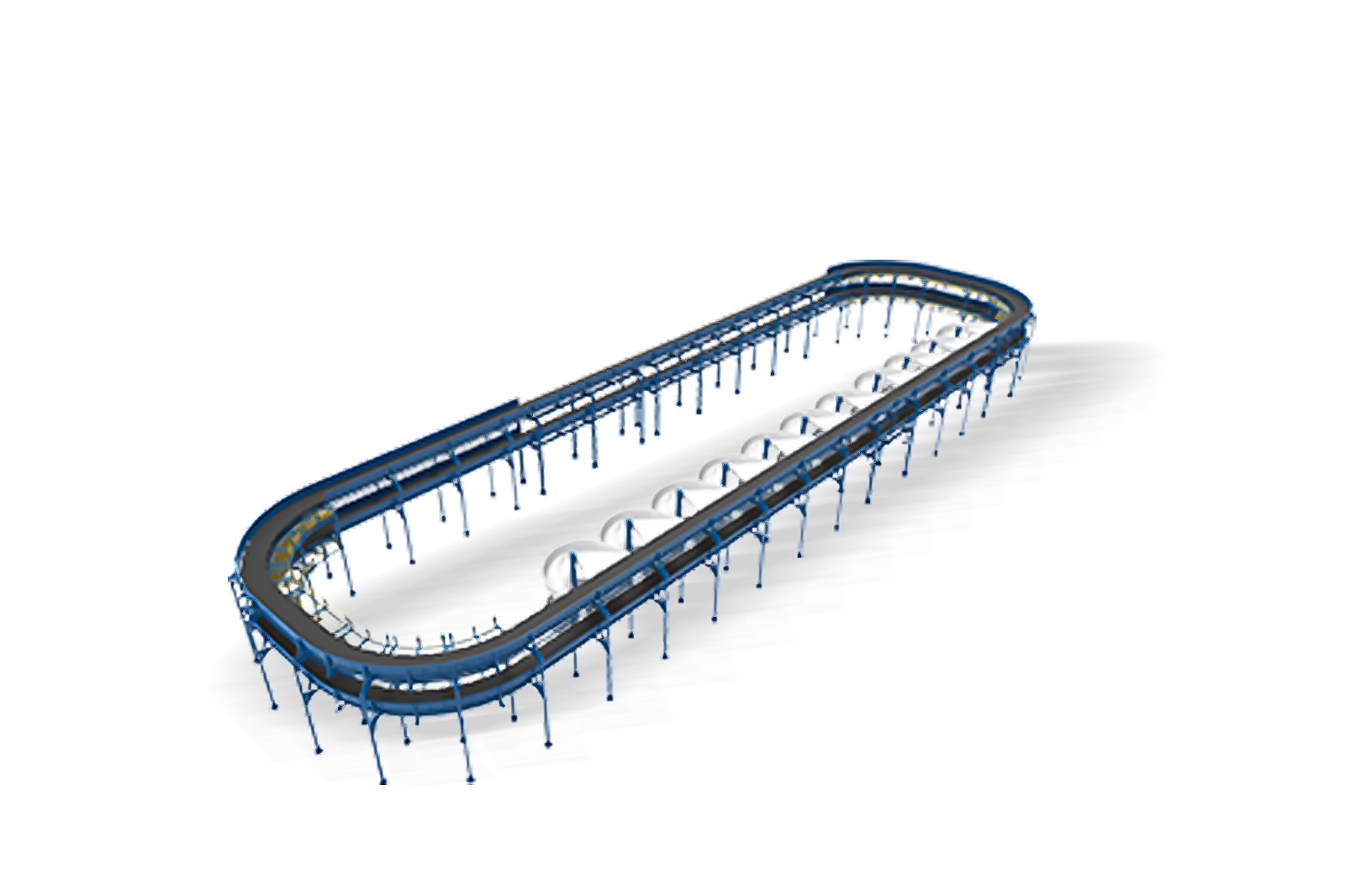

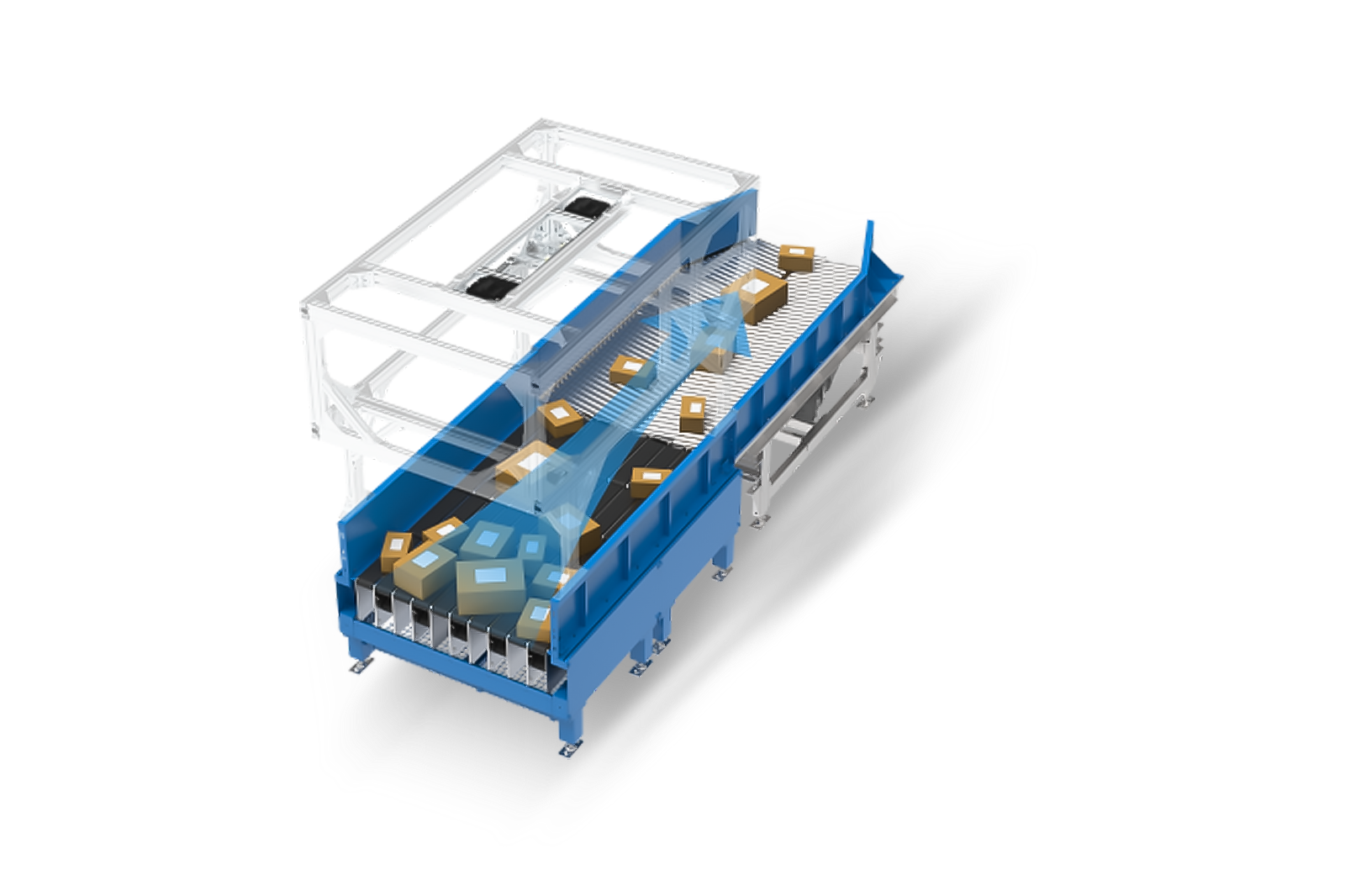

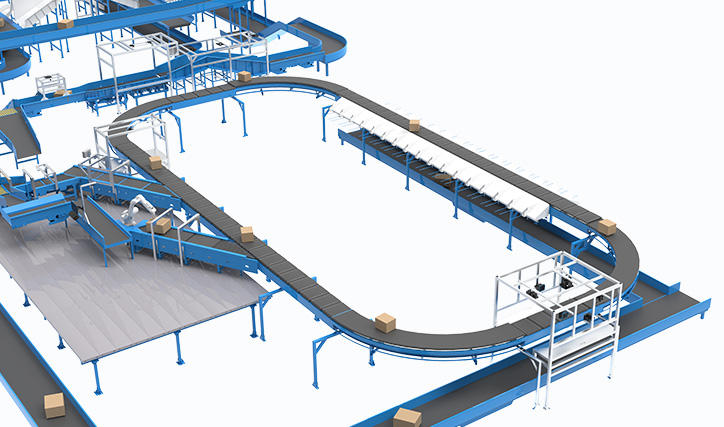

Solution for Small Parcel Sorting

The solution of Wayzim is provided in several types of cross belts such as loop, linear and narrow belts. It is an overall solution for small parcel consolidation through efficient infeed, precise barcode identification, and accurate sorting & parcel into-outlet.

In-depth customization

It can be customized to match different mainline speeds and maximize sorting capacity.

Multi-layer configuration

The flexible design of the multi-layered cross-belt configuration doubles the picking efficiency while saving a great deal of manpower and space.

Standard control

Good cost control can be achieved with standard equipment control.

Accessibility recognition

The barcode recognition technology based on high-resolution image processing can identify difficult-to-measure items such as envelopes, water-proof bags, and black express parcels without accessibility.