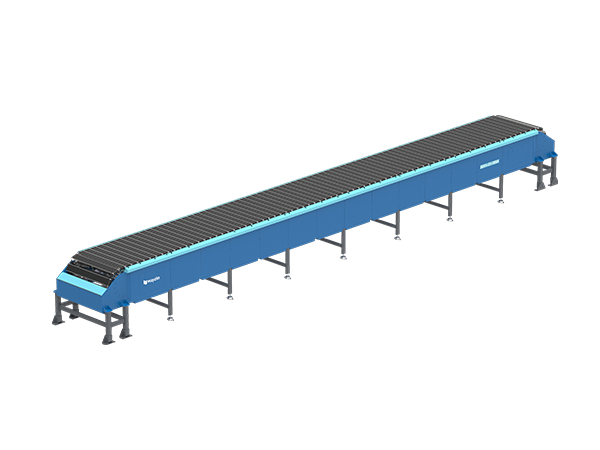

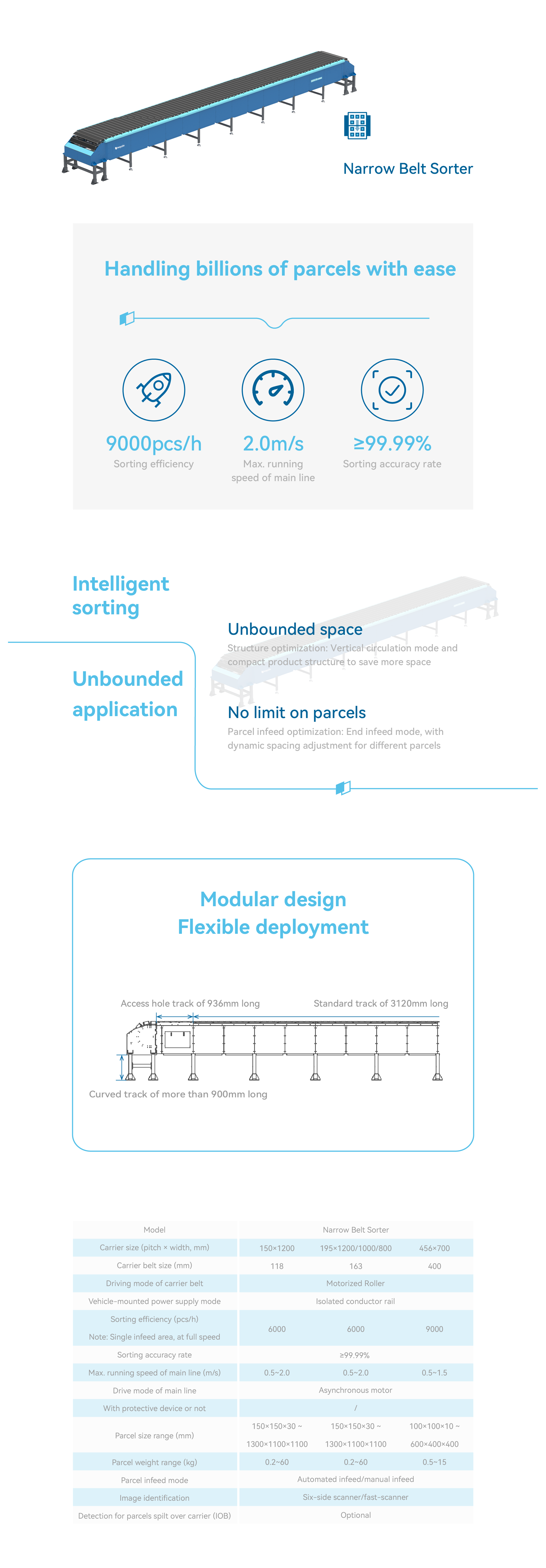

Narrow Belt Sorter

Narrow Belt Sorter uses the two-way rotating carriers as the loading and sorting units, which are arranged on the specific driving main line and sort the parcels through continuous cycle operation. The vertical circular layout is adopted in the structure, which is compact. The pitch of the sorting carriers is shorter, which is suitable for sorting of both large and small parcels .

The narrow-belt sorting system does not strictly limit the size of parcels, and can sort large parcels, small parcels and cartons at the same time.

- 9000pcs/h

- 2.0m/s

- >99.99%

- Unbounded Space

- No Limit on parcels

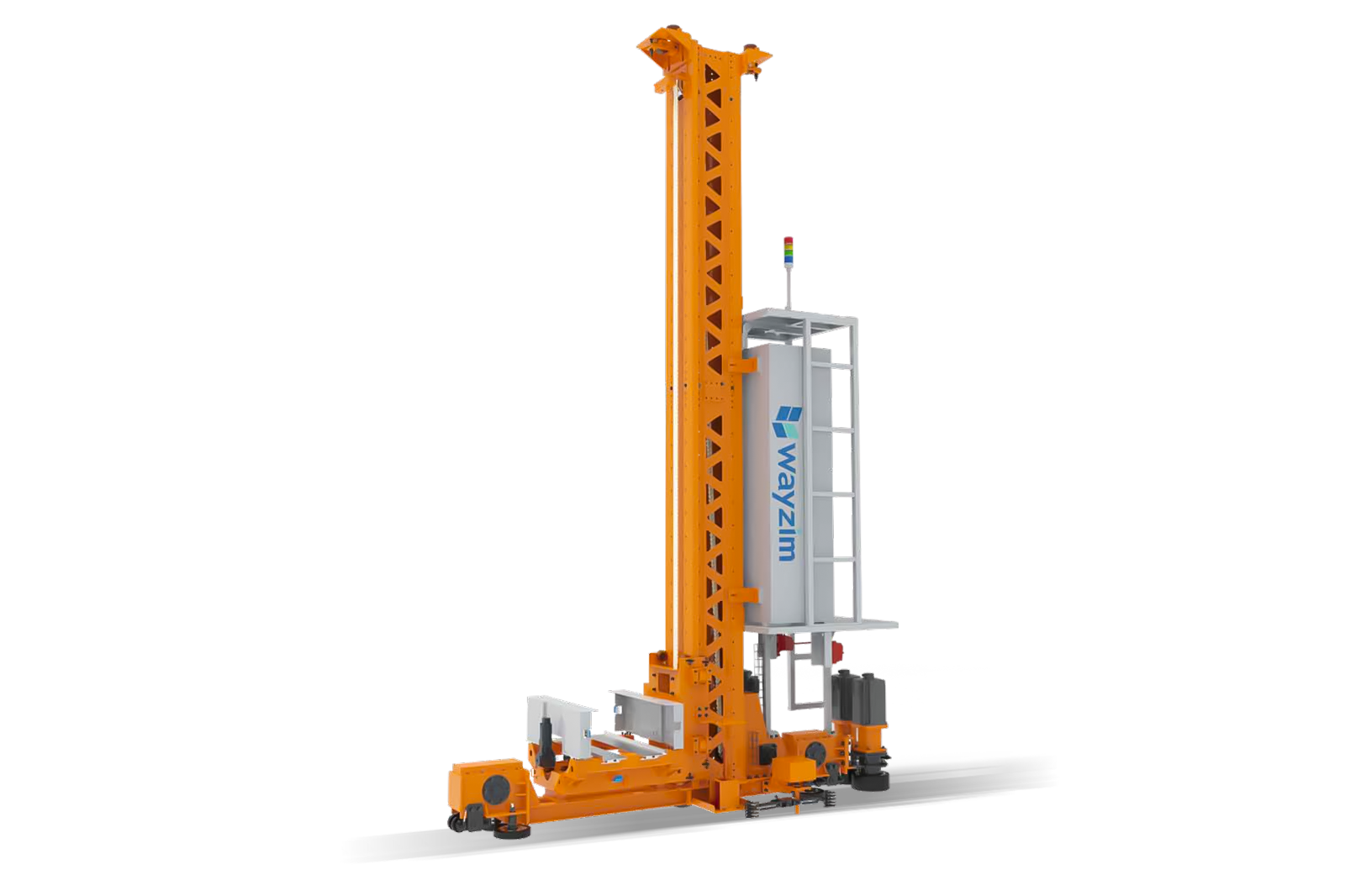

Permanent magnet motor drive extends service life and ensures structural stability

Powered by a high‑efficiency permanent magnet linear motor, the sorter delivers precise, responsive performance with minimal energy loss. Each carrier is securely affixed using robust chain plates and precision joint bearings, effectively eliminating the wear‑and‑tear issues typical of traditional reciprocating fork systems. Furthermore, the design incorporates over three times the necessary redundancy in both the carrier chain plates and structural profiles, ensuring exceptional stability and long‑term reliability across continuous industrial operations.

Modular design features high compatibility

Featuring a modular architecture, sorting modules can be added or removed effortlessly to match evolving operational demands. This versatile setup accommodates parcels of varying sizes and shapes, seamlessly executing mixed loads of large and small items to optimize throughput and maintain handling accuracy.

Multi-dimensional visual measurement ensures stable parcel discharge

The visual system and light curtain are configured to detect parcel positions and dynamically adjust sorting parameters for accurate parcel discharge: Measure the length of parcels before discharge, and when the length exceeds the configured length, carriers are grouped to allow the long parcel to be discharged at an angle, to ensure stable discharge.

Energy-saving, stable, and low-noise operation

EVA noise reduction foams/sealing strips are attached to the side of carriers and polyurethane travel wheels are used to reduce the noise of the equipment itself. According to tests, the noise at the equipment head and tail sections is ≤ 75 dB (A), and the noise at the middle section is ≤ 70 dB (A), meeting international standards.

Technical Parameters

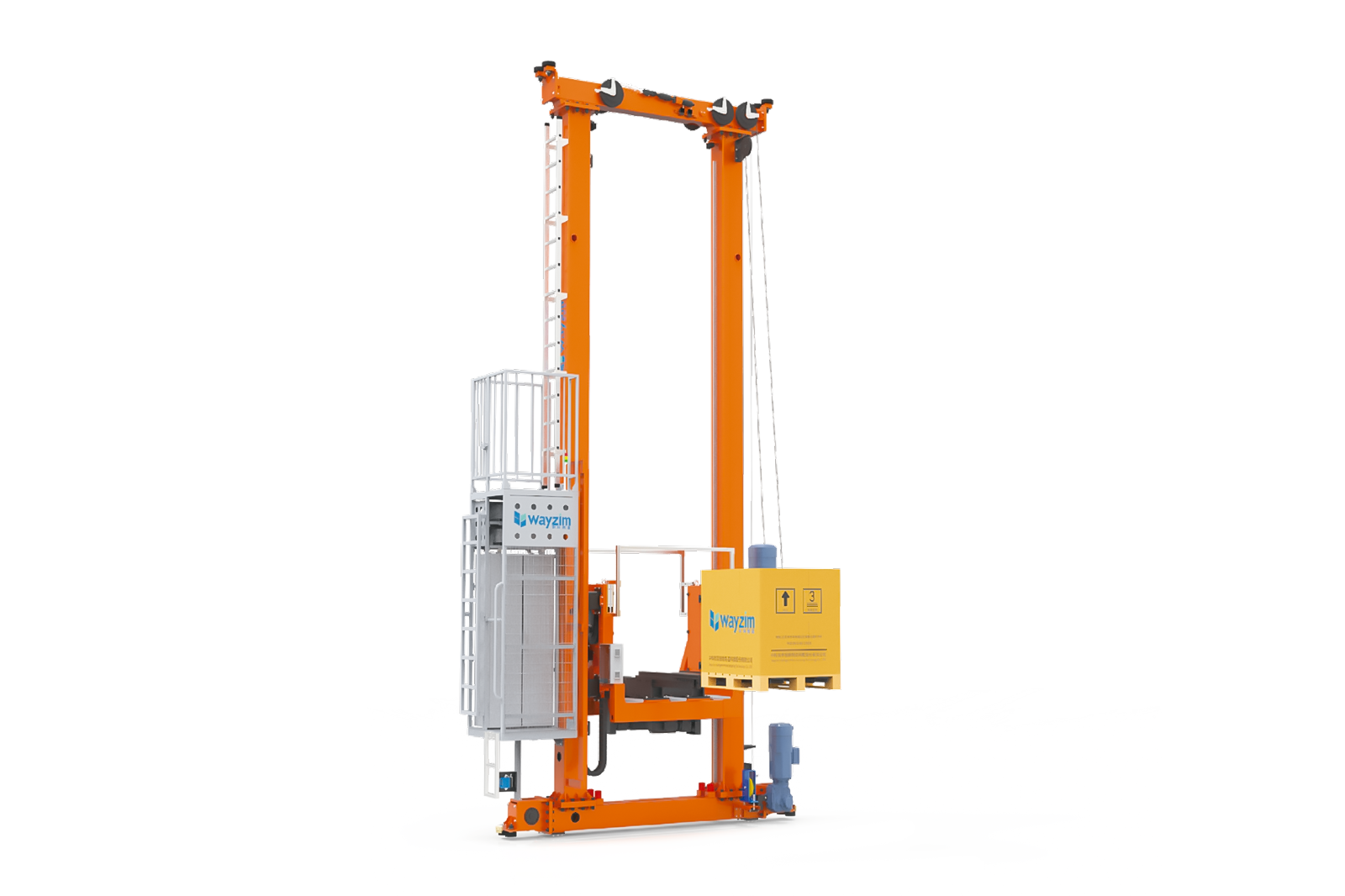

The 200 Narrow Belt Sorter is engineered for high-performance parcel sorting with a versatile design tailored for varying parcel dimensions and weights. Available with carrier dimensions of 200 × 1,200 mm, 200 × 1,000 mm, and 200 × 800 mm, each carrier has a consistent belt width of 163 mm. Utilizing a motorized roller belt drive mechanism, the sorter ensures reliable, smooth parcel transitions. Power is consistently supplied via an isolated conductor rail system, enhancing operational safety and efficiency.

The Narrow Belt Sorter boasts impressive efficiency, achieving a sorting rate of up to 6,000 parcels per hour under average parcel dimensions (length: 400 mm, width: 400 mm, height: 300 mm, spacing: 300 mm). It features a main line running speed adjustable from 0.3 to 2.0 m/s, powered by a permanent magnet linear motor for precision and robust performance. To safeguard against collisions and maintain continuous operation, the system incorporates a state-of-the-art anti-collision protective device.- Parcel handling capabilities of the sorter include:

- Maximum parcel dimensions up to 1,300 × 1,100 × 1,000 mm

- Minimum parcel dimensions as compact as 150 × 150 × 10 mm

- Parcel weight handling ranging from as low as 0.2 kg up to 60 kg