Discover how Pivot Wheel Sorters revolutionise parcel handling with precision, flexibility, and reliability. Learn about their advanced features, modular design, and wide-ranging applications in the logistics and Warehousing industries.

Introduction

This article aims to deliver an overview of Pivot Wheel Sorters, exploring their operating principles, internal mechanisms, and the specific applications for which they are best suited within the logistics and warehousing industries.

The Pivot Wheel Sorter

The Pivot Wheel Sorter is a precision-guided, wheel based sorting system designed preliminary for handling a variety of parcel types, including cartons, flexible packaging, and polybags. As an independent module, it seamlessly integrates with conveyor systems and can be strategically positioned at any point along a conveyor line.

Pivot Wheel Sorters provide one of the highest flexibility and modularity among line sorting systems. They are easily configurable and can be expanded at any time by simply adding additional diverter modules and connecting conveyor sections.

The operating mechanism of Wayzim’s Pivot Wheel Sorters sets the industry standard for robustness, performance, and reliability, thanks to the integration of a dedicated 48v drum motor within each wheel unit. This design not only maximises performance but also significantly enhances reliability by eliminating single points of failure within the wheel configuration. Additionally, maintenance is streamlined, as each wheel can be independently removed and replaced within minutes, ensuring minimal downtime.

Some of the benefits of using pivot wheel sorters are listed below:

1. “Soft sorting” mode

There is no need to turn over the tray or tilt parcels at a large angle to unload, fragile items can be easily sorted

2. Flexible deployment

Can be used in combination with belt conveyors to transport goods for sorting

3. Heavy-duty transport

Maximum load capacity of up to 80kg/㎡ (depending on selected model), greatly reducing manpower and improving sorting efficiency

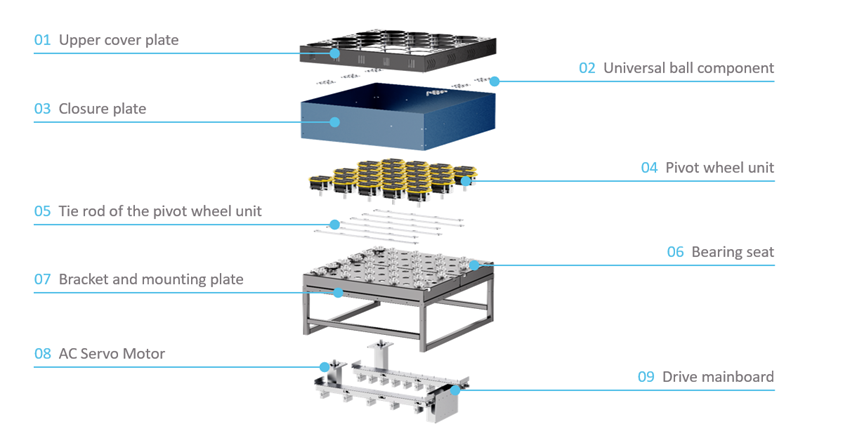

Pivot Wheel Components

The main components that make up the pivot wheel unit are listed below.

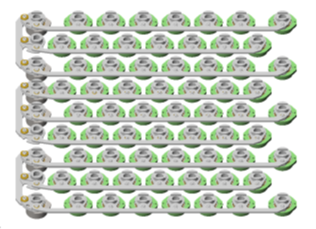

Rows of motorised rollers within the pivot wheel are organised into groups, with the number of groups determined by the specific configuration. These groups are connected to a steering mechanism, which is powered by a servo motor. When the main controller sends the steering signal, the servo motor actuates the steering plate and pull rot, enabling the entire unit to perform precise directional movements.

The number of servo motors used in each Pivot Wheel model is determined by the specific throughput and performance requirements of the application. Wayzim offers an extensive range of Pivot Wheel Diverter models, each tailored to various application scenarios.

RELATED: Pivot Wheel Sorter: Enhancing Material Flow Efficiency in Warehouses.

Pivot Wheel Operating Principle

The operating principle of pivot wheel diverters is very simple, a PEC (Photoelectric senor) is deployed just before the diverter unit, then as the parcel triggers the PEC, the signal is transferred to the pivot wheel unit which then executes the tilting action.

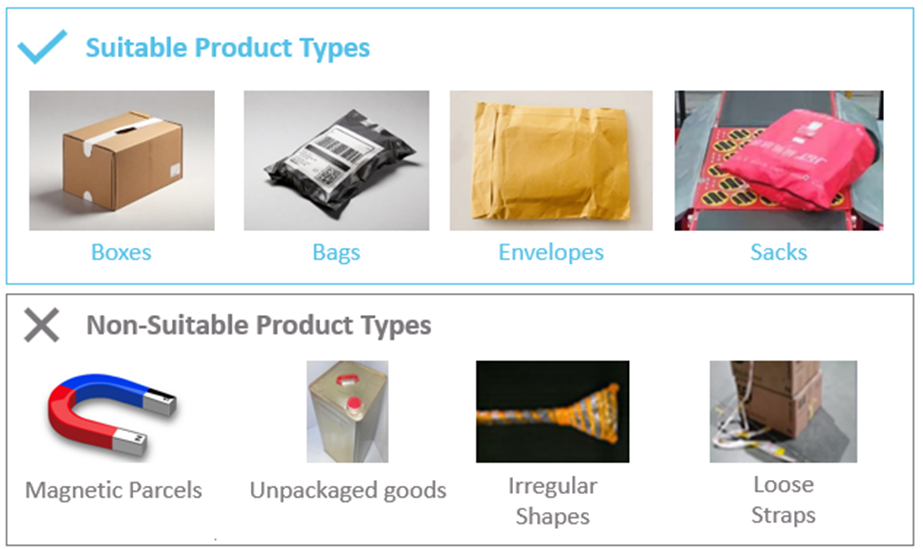

Suitable Product Types

The versatility of Pivot Wheel Sorters makes them ideal for a wide range of applications and product types. They are particularly well-suited for handling items such as boxes, bags, sacks, polybags and more.

Suitable product sizes

Suitable product sizes that a the pivot wheel diverters can handle range from a minimum size of 120x120x30mm (LxWxH) all the way up to 1200x1000x600mm (LxWxH). And depending on the selected model and running speed (1.5m/s to 2.0m/s) a sortation throughput of 4,000 PPH to 10,000 PPH can be achieved.

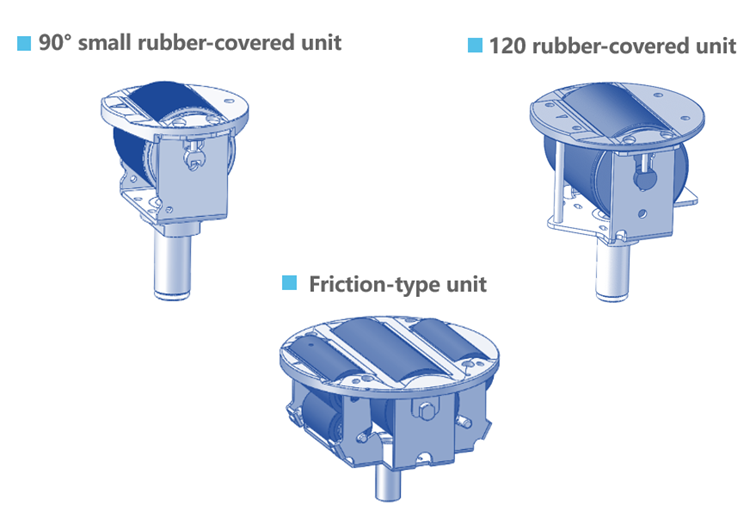

Wheel Unit Models

The wheel units are coated with polyurethane to not only enhance grip and durability, but also providing gentle handling of the parcels. There are three wheel configurations based on the application and product type.

Each Friction-Type unit features three rollers, with only the central roller being driven. The two outer rollers are powered by the internal drum motor of the central wheel. Friction-Type units are particularly effective for applications involving large sacks or bags that require additional traction for effective diversion.

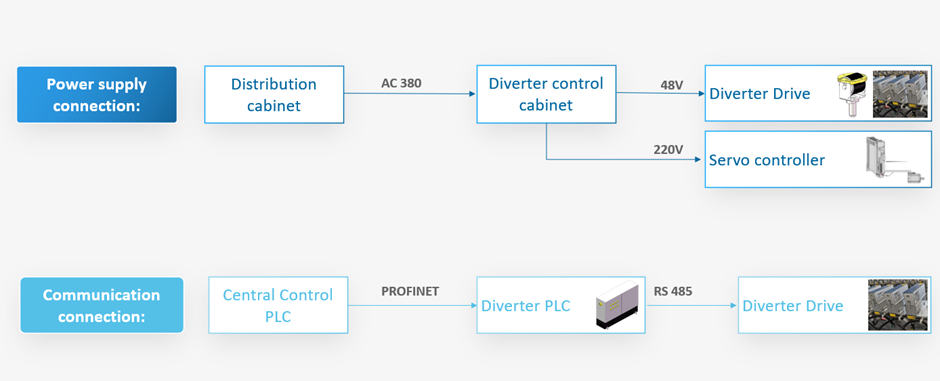

Pivot Wheel Control Cabinet & Power

Each pivot wheel unit is equipped with a dedicated electrical control cabinet, which contains essential components such as servo controllers, programmable logic controller (PLC), and power distribution panel. This configuration ensures that the pivoting action of the units is both efficient and reliable.

Communication between the customer’s central control PLC and the diverter PLC is facilitated via Profinet, a high-speed industrial network protocol. This setup enables the seamless transmission of diverting instructions and data between the central control system and the pivot wheel units, ensuring precise and coordinated operation.

Application Scenarios

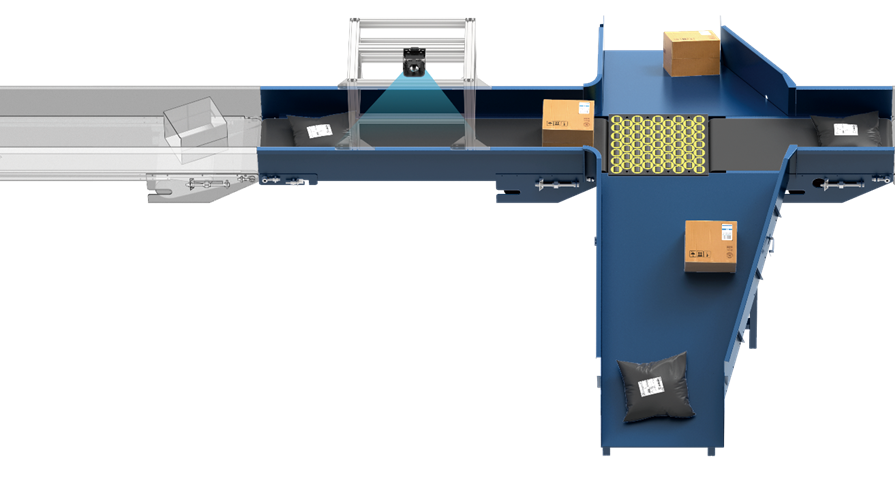

The versatility of Pivot Wheel diverters not only make them suitable for handling multiple product types at the same time, but also can be used for various applications such as sorting at unloading areas, pre-sort matrices, sorting at loading areas, automatic infeed of parcels to Crossbelt sorters, diversion of bulk flow from one line to another, QC diverting and much more.

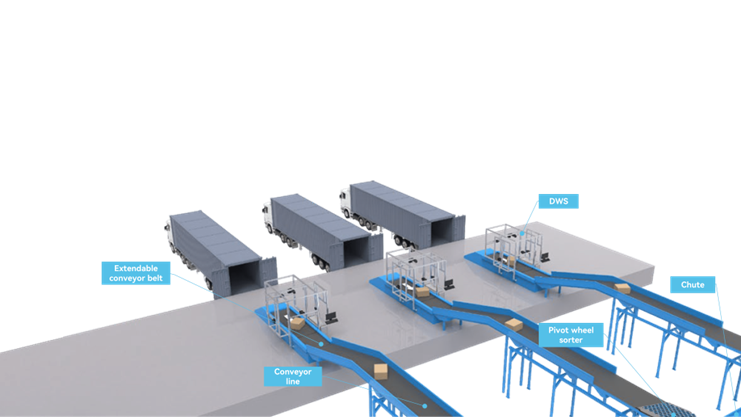

Sorting at unloading area

In the unloading area, the automatic transportation and sorting of parcels takes place after loading parcels onto the belt extendables at the inbound area. The Pivot Wheel Diverters can be used to sort parcels just after loading at inbound.

Typical equipment required for an unloading area sort comprise of belt extendable, conveyor belts, DWS (Dimensioning Weighing Scanning), Pivot Wheel Sorters and chutes.

Matrix Sorter

Pivot Wheel Diverters can be used in conjunction with conveyor belts to form a matrix sorter. Matrix sorters offer a high throughput, cost efficient and highly reliable parcel sorting method. Where multiple lines of Pivot Wheel Sorters are interconnected with one another via sharing the same outbound conveyors.

By sharing the same outbound destinations, this means that any parcel loaded on any of the inbound lines of the sorter can reach all of the outbound destinations. And a high throughput is achieved very easily and efficiently.

Matrix Sorters also offer the highest level of redundancy within any sortation system as they do not have any single points of failure, if one line goes down, that’s no problem as all a the other lines can take over the work.

Matrix Sorters also offers the simplest required maintenance of any high throughput sortation system as they only comprise of two critical bits of equipment, the conveyor belt and the pivot wheel diverters, making them very easy and cost effective to maintain and keep spare parts for.

Pivot Wheel Diverter for Automatic Infeed

Another great use of Pivot Wheel Diverters is the use of them in diverting parcels onto the automatic infeed lines of Crossbelt Sorters.

Diverting Bulk Flow

Other than single parcel sorting, Pivot Wheel Sorters can be used to divert the flow of parcel from one conveyor line onto another. In application scenarios where a bulk flow of parcels will need to be distributed onto another line, a pivot wheel divert can be utilised and kept in the swing angle direction, thus diverting the bulk flow line.

QC Diverting

Pivot Wheel Diverters can be used very effectively to divert products that have been flagged for inspection within the warehousing sectors.

For the intralogistics industry Pivot Wheel Diverters can be used in conjunction with 3D bulk flow detection system that automatically detects if there are stacked parcels or parcels with too small of a gap between them on the line, and the signal is sent to the pivot wheel diverter to remove the parcels from the main sortation line and re-induct them back to the start of the singulation system.

This system relies on deep learning target detection and real-time multi-target tracking technologies to accurately locate stacked parcels (or parcels not gapped correctly) in real time and output position signals.

In addition, the system is linked with the control system, Pivot Wheel Sorter, and other equipment to perform sorting and return operations.

Warranty

All of Wayzim’s Pivot Wheel Sorters are accompanied by a comprehensive one-year warranty as standard, which encompasses the provision of replacement parts and associated installation services. This Warranty ensures that any defective or malfunctioning components will be promptly addressed, thereby guaranteeing optimal performance and longevity of the equipment.

Manufacturing and Lead Times

Thanks to the extensive scale and advanced capabilities of Wayzim’s manufacturing facility in Anhui, we are able to produce pivot wheel diverters to the highest standards with remarkably short lead times. From the moment an order is placed, we can complete the manufacturing process and prepare the pivot wheel diverters for shipment within just six weeks.

Why Choose Wayzim ? Here are some of the key benefits

Some of the key benefits of choosing Wayzim as your supplier and partner for Pivot wheel diverts are:

- Modular and adaptable to multiple application scenarios

- Individual speed control for each motorized roller

- High reliability and purely electric components without the need for compressed air

- Compact footprint and easy to install

- Very flexible layout configuration, adaptable to all facilities

- High Capacity Sortation

- Easy and cost effective maintenance

- Proven technology with over 20,000 field installations

- Short lead time (6 weeks to complete manufacture from order

If you’re interested in our pivot wheel sorter range or would like to receive more information please don’t hesitate to contact us.

Source: Pouyan Korouei