Effective inventory management is a critical aspect of modern automated business operations. As companies strive to minimise costs, reduce waste, and improve customer satisfaction, the need for accurate and efficient inventory tracking has become increasingly apparent. Weighing and scanning systems have emerged as powerful tools for optimising these processes, offering a range of benefits that can help businesses stay competitive in today’s fast-paced market.

RELATED: Weighing and Scanning Systems: Enhancing Efficiency in Modern Industries.

Components of Weighing and Scanning Systems

A comprehensive weighing and scanning system consists of several key components, each playing a crucial role in the overall functionality and performance of the system. These components include:

1. Scales: High-precision scales, such as bench scales and floor scales, are essential for accurately measuring the weight of products and materials.

These scales are designed to handle a wide range of weights and sizes, ensuring that businesses can accurately track inventory across various product categories.

2. Barcode Scanners: Barcode scanners, available in handheld and fixed-mount configurations, are used to quickly and accurately capture product information by reading barcodes. These scanners integrate seamlessly with inventory management software, allowing for real-time updates and data analysis.

3. Software: Inventory management software is the central hub of a weighing and scanning system. This software collects, stores, and analyses data from the scales and scanners, providing businesses with valuable insights into their inventory levels, product movements, and overall efficiency.

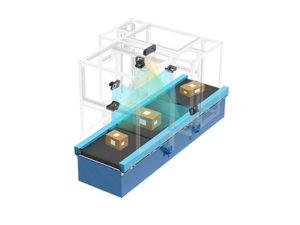

4. Conveyor Systems: In some cases, automated conveyor systems can be integrated into the weighing and scanning process to further streamline operations. These systems move products efficiently through the scanning and weighing stations, reducing manual labor and increasing throughput.

Benefits of Implementing Weighing and Scanning Systems

The implementation of weighing and scanning systems offers a range of benefits for businesses seeking to optimise their inventory management processes. These benefits include:

1. Increased Accuracy: By utilising high-precision scales and scanners, businesses can significantly reduce the risk of errors associated with manual data entry and measurement. This improved accuracy leads to more reliable inventory data and better decision-making.

2. Enhanced Efficiency: Automated weighing and scanning processes can greatly reduce the time and labor required for inventory tracking. This increased efficiency allows businesses to process more items in less time, ultimately leading to cost savings and improved productivity.

3. Real-time Data Access: Weighing and scanning systems provide real-time data on inventory levels, product movements, and other key metrics. This up-to-date information enables managers to make informed decisions quickly, responding to changes in demand or supply chain disruptions as they occur.

4. Cost Savings: By streamlining processes, reducing errors, and minimising manual labor, weighing and scanning systems can help businesses reduce costs associated with inventory management. These cost savings can be reinvested in other areas of the business or used to improve profitability.

RELATED: Understanding Dimensioning Weighing Scanning Systems: Detail Explanation.

Implementing Weighing and Scanning Systems

To successfully implement a weighing and scanning system, businesses should follow a structured approach that includes:

1. Needs Assessment: Begin by evaluating current inventory management processes and identifying areas where weighing and scanning technology can provide the most significant benefits.

2. Component Selection: Choose scales, scanners, and software that align with your business’s unique needs and integrate seamlessly with existing systems.

3. Staff Training: Ensure that employees are properly trained on the use of the new equipment and software, focusing on best practices for accuracy and efficiency.

4. Continuous Improvement: Regularly monitor the performance of the weighing and scanning system, making adjustments and improvements as needed to optimise results.

Weighing and scanning systems offer a powerful solution for businesses seeking to optimise their inventory management processes. By leveraging advanced technology and automation, these systems can help companies reduce errors, increase efficiency, and make better-informed decisions based on real-time data. As the demand for streamlined inventory management continues to grow, the adoption of weighing and scanning systems is likely to become increasingly widespread across various industries.

FAQs

1. Q: Can weighing and scanning systems be customised to meet specific business requirements?

A: Yes, many weighing and scanning systems offer a high degree of customisation, allowing businesses to tailor the components and software to their unique needs and workflows.

2. Q: How does the accuracy of weighing and scanning systems compare to manual methods?

A: Weighing and scanning systems are designed to provide significantly higher levels of accuracy compared to manual methods. By utilising high-precision scales and scanners, these systems minimise the risk of human error and ensure consistent, reliable data capture.

3. Q: What industries can benefit from implementing weighing and scanning systems?

A: Weighing and scanning systems can be beneficial for a wide range of industries, including manufacturing, logistics, retail, and healthcare. Any business that relies on accurate inventory tracking and management can potentially benefit from these systems.

4. Q: How can businesses ensure a smooth transition when implementing a weighing and scanning system?

A: To ensure a smooth transition, businesses should develop a comprehensive implementation plan that includes needs assessment, component selection, staff training, and continuous improvement. Partnering with experienced vendors and providing ongoing support can also help minimise disruptions during the implementation process.

5. Q: What role does software play in a weighing and scanning system?

A: Software is a critical component of a weighing and scanning system, serving as the central hub for data collection, storage, and analysis. The software integrates with the scales and scanners, providing real-time updates and insights into inventory levels, product movements, and overall system performance.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out SmartlogitecX sales team for your customised automation solution.