In the world of order fulfilment and distribution, efficiency is key to meeting customer expectations and maintaining a competitive edge. One essential tool for streamlining these processes is the linear sorter. These automated sorting systems are designed to quickly and accurately sort products, packages, and other items based on predefined criteria, such as destination, product type, or shipping method.

RELATED: Linear Sorter: An Efficient Material Handling Solution.

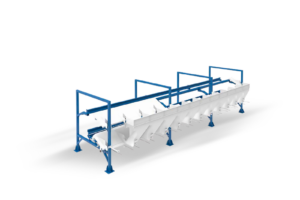

A linear sorter typically consists of a main conveyor line that transports items through the system, along with a series of diverting mechanisms positioned at strategic points along the line. As items pass by these diverters, they are scanned or identified using barcodes, RFID tags, or other tracking technologies. Based on the information gathered, the system controls the diverters to guide each item onto the appropriate outbound lane or chute, ensuring accurate sorting and routing.

The benefits of implementing a linear sorter in your operation are numerous. First and foremost, these systems can significantly increase throughput and productivity by automating the sorting process and reducing the need for manual handling. This not only saves time and labour costs but also minimises the risk of human error, leading to improved accuracy and fewer missorts. Linear sorters are also highly versatile and can handle a wide range of product sizes, shapes, and weights, making them suitable for various industries and applications.

Another advantage of linear sorters is their modular and scalable design. As your business grows and your sorting needs evolve, these systems can be easily expanded or reconfigured to accommodate higher volumes or new product lines. This flexibility ensures that your investment in a linear sorter will continue to provide value and support your operation over the long term.

When considering a linear sorter for your facility, it’s essential to work with an experienced and reputable vendor who can assess your specific requirements and recommend the best solution for your needs. Factors to consider include throughput goals, product characteristics, available space, and integration with existing systems and processes. A knowledgeable vendor will also provide guidance on system layout, maintenance requirements, and operator training to ensure optimal performance and longevity of your linear sorter.

Linear sorters are an ideal solution for a variety of industries and applications, including e-commerce fulfilment centres, retail distribution hubs, postal and parcel handling facilities, and manufacturing and assembly operations. By automating and streamlining the sorting process, these systems enable businesses to improve efficiency, reduce costs, and enhance customer satisfaction.

RELATED: Linear Sorters: Streamlining Order Fulfillment with Efficiency and Flexibility

Frequently Asked Questions (FAQs)

1. What is the typical throughput of a linear sorter?

The throughput of a linear sorter can vary depending on factors such as the size and complexity of the system, the characteristics of the items being sorted, and the number of outbound lanes or destinations. On average, linear sorters can handle between 2,000 and 10,000 items per hour, with some high-capacity systems capable of even higher throughput rates.

2. Can a linear sorter handle items of different sizes and weights?

Yes, linear sorters are designed to accommodate a wide range of product sizes and weights. Most systems can handle items ranging from small, lightweight envelopes to larger, heavier packages or even totes and containers. The specific size and weight limits will depend on the particular model and configuration of the sorter.

3. How does a linear sorter ensure accurate sorting?

Linear sorters use advanced tracking and identification technologies, such as barcode scanners or RFID readers, to precisely identify and locate each item as it moves through the system. This information is then used to control the diverting mechanisms, ensuring that each item is accurately sorted and routed to the correct destination.

4. What maintenance is required for a linear sorter?

Regular maintenance is essential to ensure optimal performance and longevity of your linear sorter. This typically includes routine inspections, cleaning, and lubrication of key components, as well as prompt repair or replacement of worn or damaged parts. Preventive maintenance, such as regular belt adjustments and alignment checks, can also help prevent downtime and extend the life of your system. Your vendor should provide comprehensive maintenance guidelines and support to keep your linear sorter running smoothly.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.