In the fast-paced world of modern aviation, the efficient operation of automated baggage handling systems is crucial for both airlines and passengers. At the heart of these systems lies the automated baggage sorting system, responsible for seamlessly transferring luggage from check-in, conveyor, and identification systems to their final destinations.

Client Pain Points

With the increasing passenger traffic and baggage handling demands, a regional airport in Central China faced several challenges with its automated baggage sorting system:

Low Ceiling Height

The airport, being a small regional facility, has a baggage sorting area with low ceiling heights, poor lighting, and a challenging working environment.

High Sorting Pressure

With an annual passenger throughput exceeding one million, the airport’s sorting centre struggles to meet demand during peak times with manual sorting alone.

Wayzim’s Solution

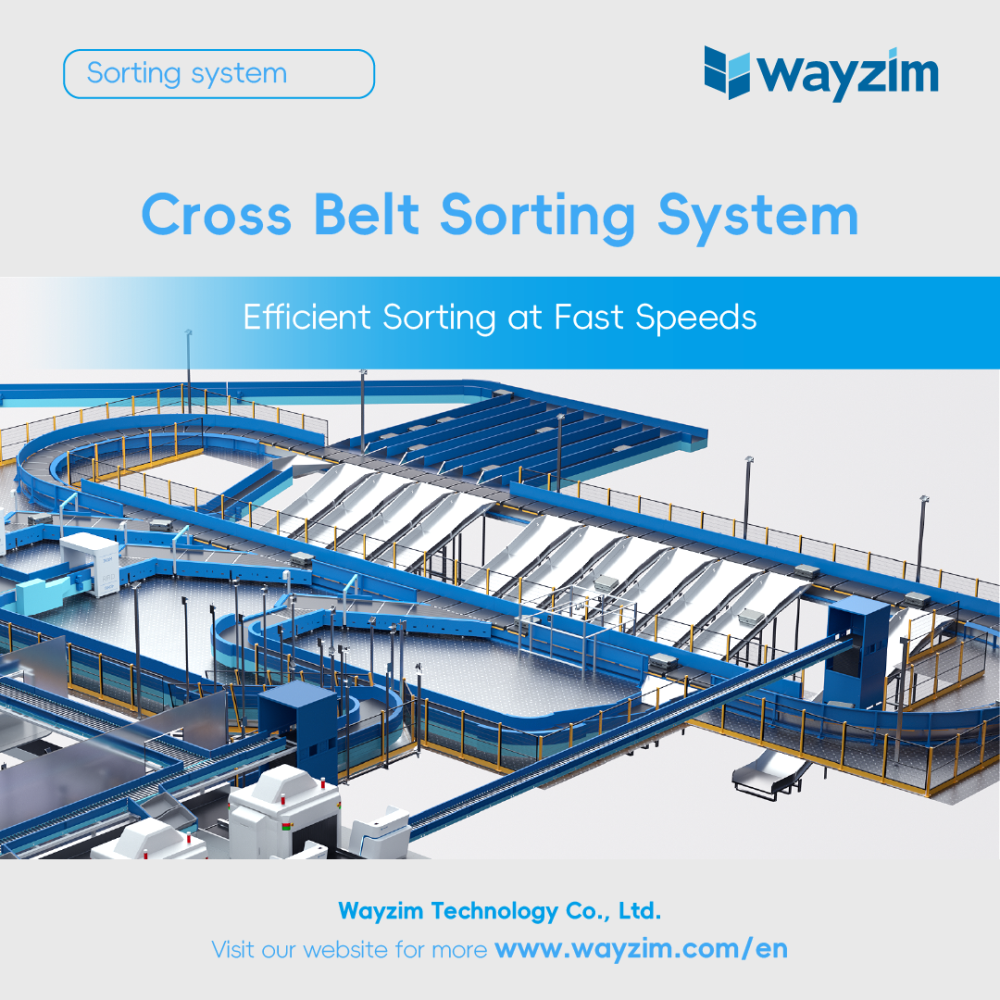

Wayzim’s professional technical team conducted on-site inspections and project analyses, adopting a loop cross belt sorting system to address the limited sorting space. This approach ensures high compatibility between equipment and venue, achieving efficient automated baggage sorting. The system is comprised of three main components: the departure system, arrival system, and control system, with a total equipment length of approximately 900 meters. It is designed to handle an annual passenger throughput of five million and 45,000 aircraft movements.

- Departure System: Standard baggage departure system, large baggage departure system, circular cross-belt sorting system, baggage tag camera recognition system.

- Arrival System: Multiple flat extraction carousels.

- Control System: Electrical and control systems, information processing systems, equipment monitoring systems, and video monitoring systems.

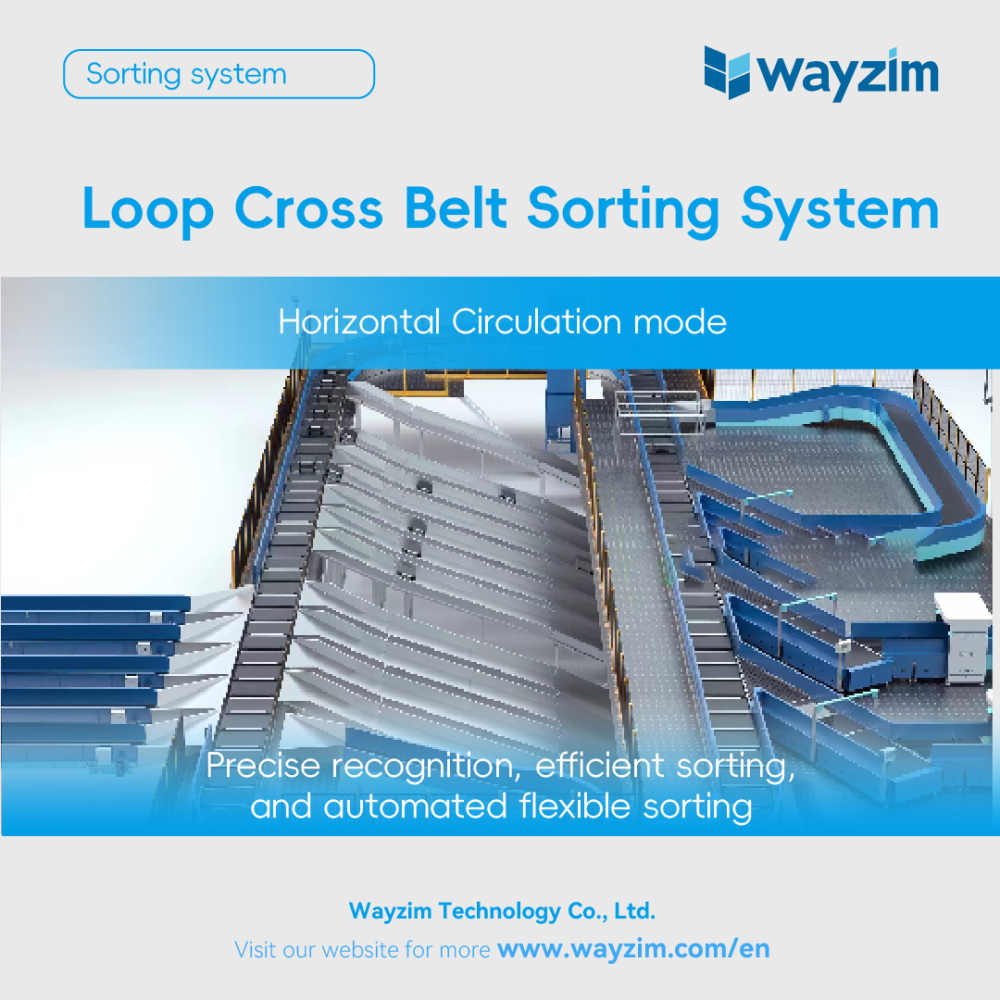

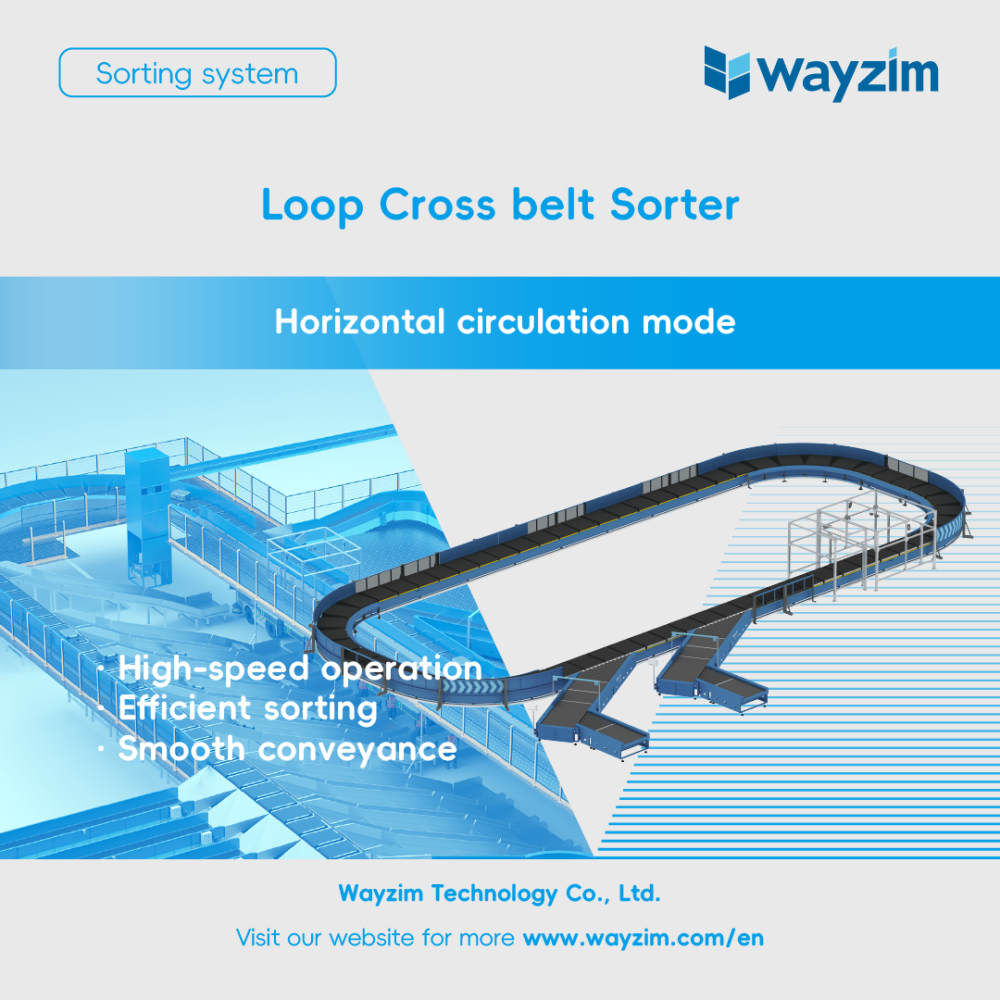

Loop Cross Belt Sorting System

System Overview

The loop cross belt sorting system, consisting of a loop cross belt sorter, induction system, and identification equipment, is a key tool for efficient automated baggage sorting. Utilising a closed-loop, horizontal circulation method, it ensures efficient, precise, flexible, and damage-free sorting, suitable for medium to large and hub airports.

Implementation Effect

- Efficient Sorting: The circular sorting mode achieves a sorting efficiency of ≥4800 pieces per hour.

- Flexible Sorting: The sorting carts, driven by friction belts, actively output baggage with minimal drop height, ensuring flexible sorting.

- Precise Control: The sorting carts use sine wave electric roller servos for precise control of speed and distance, maintaining an error margin within 1%.

Core Equipment of Loop Cross Belt Sorter

The bidirectional rotating belt conveyors are taken as the bearing and sorting units, and arranged in the horizontal ring specific drive main line, to achieve the automatic baggage sorting function according to the flight information and flight distribution plan.

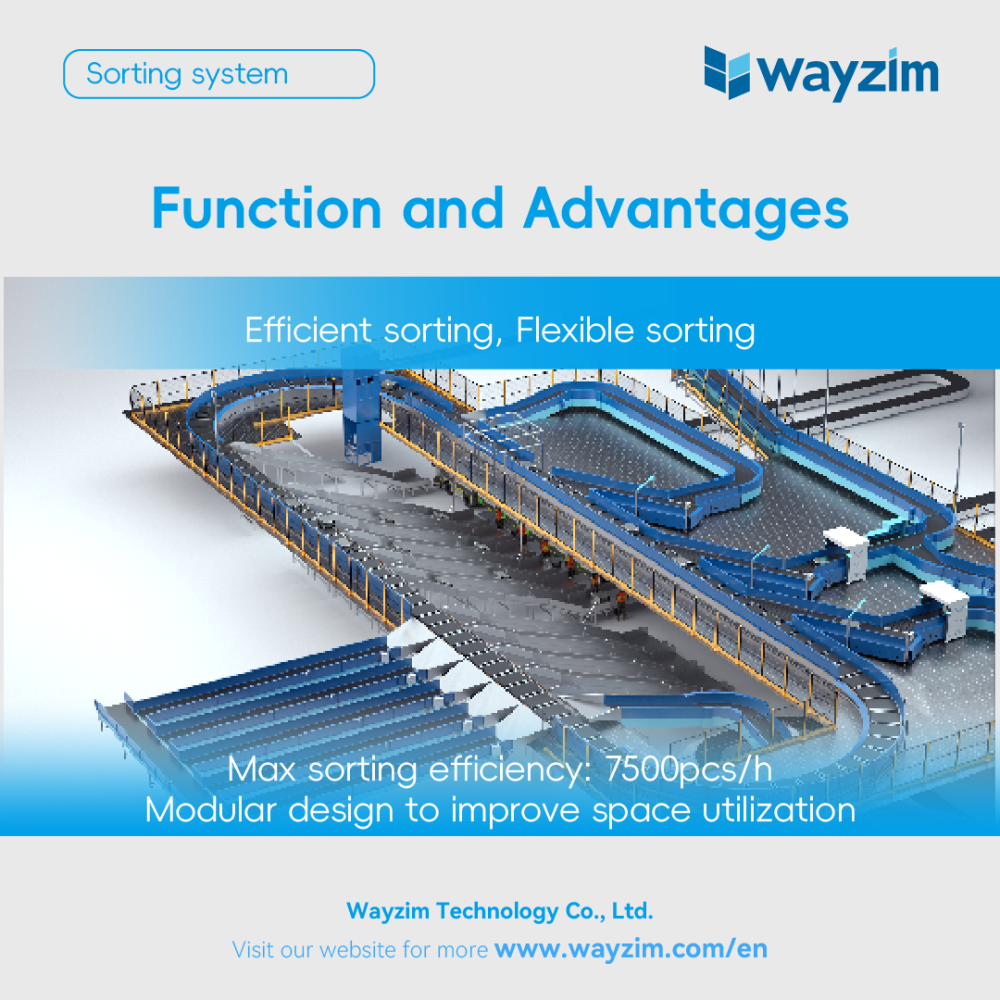

Advantages of the Loop Cross Belt Sorter

- High-speed operation: The equipment supports mainline running speeds of up to 2.5 m/s, greatly improving sorting efficiency.

- Efficient sorting: The equipment has a strong baggage handling capacity, easily meeting the baggage sorting needs during peak periods.

- Smooth conveyance: The equipment is equipped with high-friction belts so that baggage does not slip off the belt at curves when the sorter is running at a high speed.

Our professional team and core technology in automated baggage handling systems offer reliable solutions for airlines, improving service quality and customer satisfaction while achieving intelligent and efficient baggage handling. Interested in more details and demonstrations? Feel free to contact us!