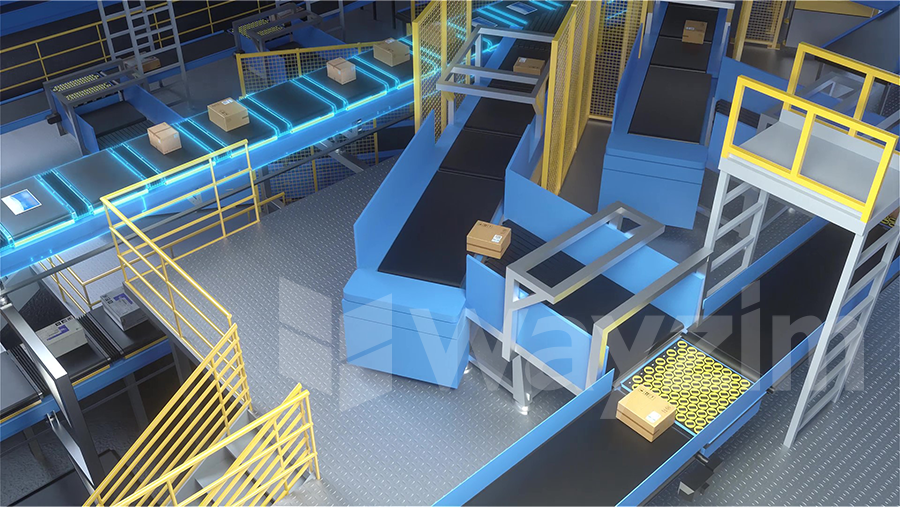

In the logistics sorting scenario, how can various automated logistics systems, such as barcode scan systems, conveyor systems, and sorting systems, efficiently collaborate to sort a large number of parcels with multiple categories and specifications? As an independent module, the Pivot Wheel Sorter can be seamlessly integrated into a logistics system and can be adapted to different customer needs for flexible strategic deployment on the conveyor line. The Pivot Wheel Sorter achieves flexible sorting, ensures a smooth transition of sorting tasks, and improves sorting efficiency and circulation efficiency.

The Pivot Wheel Sorting System is a precisely controlled wheel sorting system, mainly used for sorting various types of parcels including cartons, soft bags, and plastic bags. The modular design of the Pivot Wheel Sorting System determines its highly flexible sorting property. As independent sorting modules, Pivot Wheel Sorters are easy to configure and can be flexibly added to the connected conveyor system to expand solutions, actively coping with peak sorting periods.

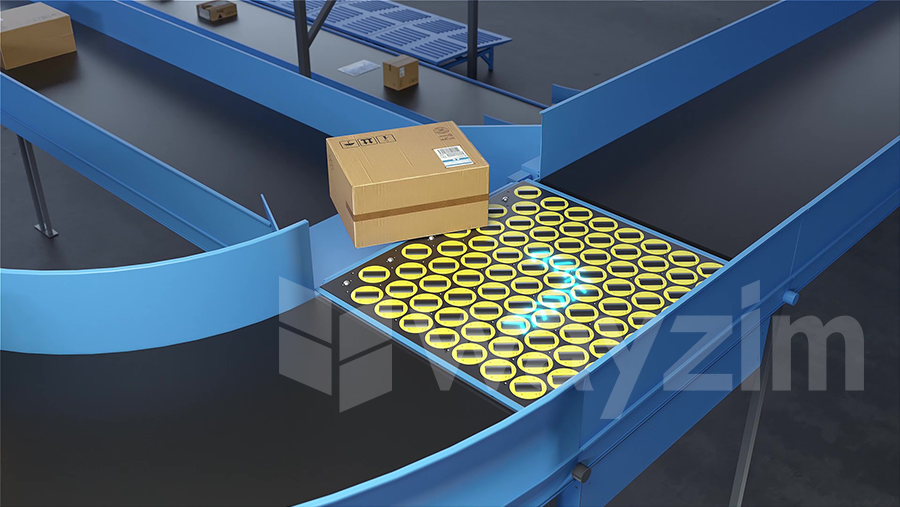

Wayzim’s Pivot Wheel Sorting System provides assurance in robustness, sorting performance, and reliability, thanks to the dedicated 48V roller motor integrated into each wheel unit. This design not only maximises product performance but also effectively avoids the shutdown of the entire system caused by single points of failures in a wheel group, thereby enhancing overall system reliability. In addition, each roller can be disassembled and replaced within a few minutes, ensuring that equipment maintenance can be completed with minimal downtime. The operation is simple, and the maintenance cycle and costs are greatly reduced.

The powered roller unit of the Pivot Wheel Sorting System, in conjunction with the central control system, can seamlessly transmit sorting instructions and data, achieving precise sorting of parcels of all categories and specifications. The Pivot Wheel Sorting System has outstanding advantages in sorting large and heavy items.

● Standardised series products fully adapt to different scenario requirements

The unit module can use the coated motorised roller or friction disc to meet the sorting needs of different types of parcels. The main line running speed can reach up to 2.3 m/s, and the equipment can achieve adaptive speed adjustment of parcel spacing. Two, four, six, or more groups of steering units can be flexibly combined, with the maximum sorting efficiency in single-sided sorting mode reaching 10,000 pcs/h.

● Modular design for quick deployment and maintenance

The number of rows and columns for unit modules can be freely arranged, and the size of unit modules can be customised based on requirements, to meet the sorting needs of different sizes of parcels. Each unit module is independent of each other, making the system highly fault-tolerant and enabling quick deployment and maintenance.

● Flexible use, matched with various types of conveying and sorting equipment

The Pivot Wheel Sorter uses distributed and bus control and communication systems and can be flexibly combined with various types of equipment, such as telescoping conveyors, belt conveyors, DWS systems, and 2D Bulk Flow Singulators, to achieve full-process automated sorting of parcels. The sorter has outstanding advantages in sorting large and heavy goods, playing an important role in sorting scenarios such as unloading areas, QC diverting, sorting areas for consolidation bags of small parcels, and loading areas.

The Wayzim Pivot Wheel Sorting System can not only sort multiple types of parcels, but also is suitable for various sorting scenarios, such as unloading/loading area sorting, pre-sorting matrix, automated parcel induction into the cross belt sorting system, high-flow diverting, and QC diverting.

01 Rough sorting by pivot wheel sorters in unloading areas

The Pivot Wheel Sorting System can be used for the rough sorting of large quantities of parcels in the unloading area, and the parcels are automatically transported and sorted in the inbound area through the extension of the conveyor belt.

02 Matrix Pivot Wheel Sorting Systems

Pivot wheel sorting systems can be combined with conveyor belts to form matrix Pivot Wheel Sorting Systems. Multiple pivot wheel sorting lines share the outbound conveyor belt, so that parcels on any inbound line can reach all outbound destinations. In this way, a high-throughput and efficient parcel sorting solution is provided.

03 Automated infeed for the cross-belt sorting system

Another important use of the Pivot Wheel Sorting System is to divert parcels to the automated infeed line of the cross-belt sorting system to prepare for the efficient sorting of the cross-belt sorting system.

04 High-flow diverting area

In addition to sorting separate parcels, the Pivot Wheel Sorting System is also suitable for dispersing parcel flows and diverting large quantities of parcels from one conveyor line to another, thus improving sorting efficiency.

05 QC diverting

The Pivot Wheel Sorting System can cooperate with Wayzim 3D vision detection systems to automatically detect whether there are stacked parcels or parcels with too small a gap on the conveyor line. If so, the Pivot Wheel Sorting System moves these parcels out of the main sorting line and returns these parcels.

With its modular design, flexible deployment, and efficient operation, Wayzim’s Pivot Wheel Sorting System has become an indispensable core sorting equipment in the modern logistics industry. Through close cooperation with other intelligent systems, the Pivot Wheel Sorting System not only improves sorting accuracy and efficiency, but also creates more competitive operational advantages for logistics enterprises.

In the future, Wayzim will continue to promote technological innovation and help the global logistics industry move towards a new era with more intelligence and automation.