Narrow Belt Sorter has long been a reliable solution for efficient and flexible parcel sorting. With its bi-directional rotating carriers and vertical circulating layout, it seamlessly handles parcels of various shapes and sizes—be it large cartons or small packages—all while maximising space utilisation.

Let’s take a look at its detailed structure, as shown in the image below, showcasing how components like the carrier, shock absorber, and upper track work together to ensure precision and reliability in logistics operations.

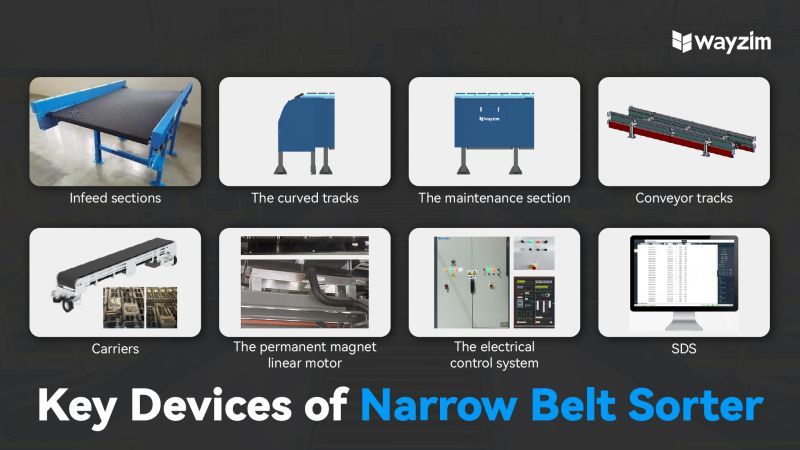

Key Devices of Narrow Belt Sorter

Narrow Belt Sorter is powered by an advanced combination of devices, each designed for precise and efficient parcel handling:

1.𝐇𝐞𝐥𝐥𝐈𝐧𝐟𝐞𝐞𝐝 𝐒𝐞𝐜𝐭𝐢𝐨𝐧𝐬: Convey parcels to carriers with adjustable speeds tailored to sorting needs.

2.𝐓𝐡𝐞 𝐂𝐮𝐫𝐯𝐞𝐝 𝐓𝐫𝐚𝐜𝐤𝐬: Ensure seamless changes in carrier direction at the head and tail of the sorter.

3.𝐓𝐡𝐞 𝐌𝐚𝐢𝐧𝐭𝐞𝐧𝐚𝐧𝐜𝐞 𝐒𝐞𝐜𝐭𝐢𝐨𝐧: Simplifies the replacement and repair of faulty carriers, ensuring uninterrupted operations.

4.𝐂𝐨𝐧𝐯𝐞𝐲𝐨𝐫 𝐓𝐫𝐚𝐜𝐤𝐬: Provide stable carrier movement with precise positioning through guide wheels.

5.𝐂𝐚𝐫𝐫𝐢𝐞𝐫𝐬: Enable parcel sorting with sequential distribution along the vertical loop track.

6.𝐓𝐡𝐞 𝐏𝐞𝐫𝐦𝐚𝐧𝐞𝐧𝐭 𝐌𝐚𝐠𝐧𝐞𝐭 𝐋𝐢𝐧𝐞𝐚𝐫 𝐌𝐨𝐭𝐨𝐫: Drives the main line for smooth, controlled sorting operations.

7.𝐓𝐡𝐞 𝐄𝐥𝐞𝐜𝐭𝐫𝐢𝐜𝐚𝐥 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 𝐒𝐲𝐬𝐭𝐞𝐦: Oversees the carrier control, safety, and maintenance systems for reliability.

8.𝐒𝐃𝐒 (𝐒𝐲𝐬𝐭𝐞𝐦 𝐃𝐚𝐭𝐚 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧): Delivers real-time data exchange and control, optimising system performance.

These devices work together to create a compact, efficient, and highly versatile sorting solution for diverse parcel handling requirements.

Efficient Power Access and Communication

Narrow Belt Sorter integrates powerful and reliable systems for smooth and uninterrupted parcel sorting operations:

1.𝐈𝐧𝐟𝐫𝐚𝐫𝐞𝐝 𝐓𝐫𝐚𝐧𝐬𝐦𝐢𝐭𝐭𝐞𝐫: Seamlessly transmits the carrier running command for precise movement.

2.𝐈𝐧𝐟𝐫𝐚𝐫𝐞𝐝 𝐃𝐫𝐢𝐯𝐞: Powers the carriers, ensuring they run with speed and accuracy.

3.𝟒𝟖 𝐕 𝐒𝐌𝐏𝐒, 𝐂𝐚𝐫𝐛𝐨𝐧 𝐁𝐫𝐮𝐬𝐡, 𝐚𝐧𝐝 𝐈𝐬𝐨𝐥𝐚𝐭𝐞𝐝 𝐂𝐨𝐧𝐝𝐮𝐜𝐭𝐨𝐫 𝐑𝐚𝐢𝐥: Delivers stable 48V power to fuel the sorting process, ensuring continuous and efficient operations.

These core components enable optimal communication and power distribution, ensuring your sorting system is both reliable and effective.

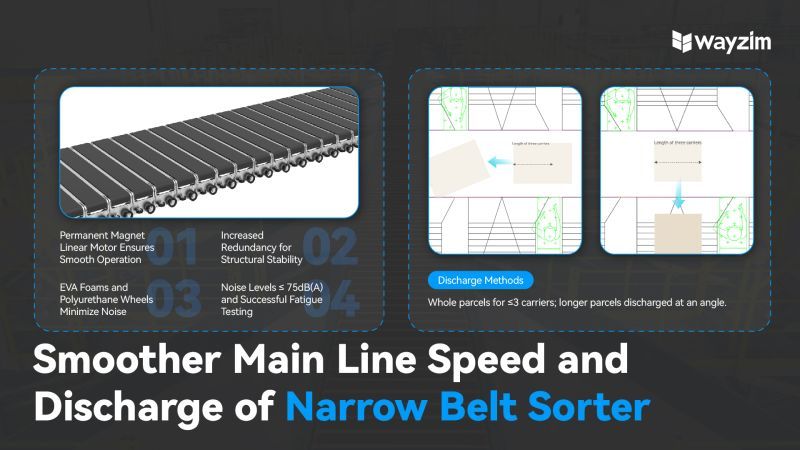

Smoother Main Line Speed and Discharge with the Narrow Belt Sorter

Stable and Reliable Operations

1.A permanent magnet linear motor drives the main line, providing a robust and stable structure while reducing mechanical wear.

2.Redundancy in design ensures system stability, even during high-demand operations.

3.EVA noise reduction foams and polyurethane travel wheels minimise operational noise for quieter performance.

Efficient and Precise Discharge

1.Integrated volume measuring instruments and centering conveyors optimise carrier allocation for smooth discharge.

2.Intelligent discharge methods handle parcels of varying sizes with precision, ensuring consistent flow and minimal disruptions.