In today’s fast-paced e-commerce and logistics landscape, efficient sorting solutions are crucial for keeping up with ever-increasing demand. One of the most advanced and versatile sorting technologies available is the cross belt sorter. These sophisticated systems are designed to handle high volumes of parcels, packages, and other items with unparalleled speed and accuracy.

RELATED: Cross Belt Sorters: Powerhouses of Warehouse Versatility

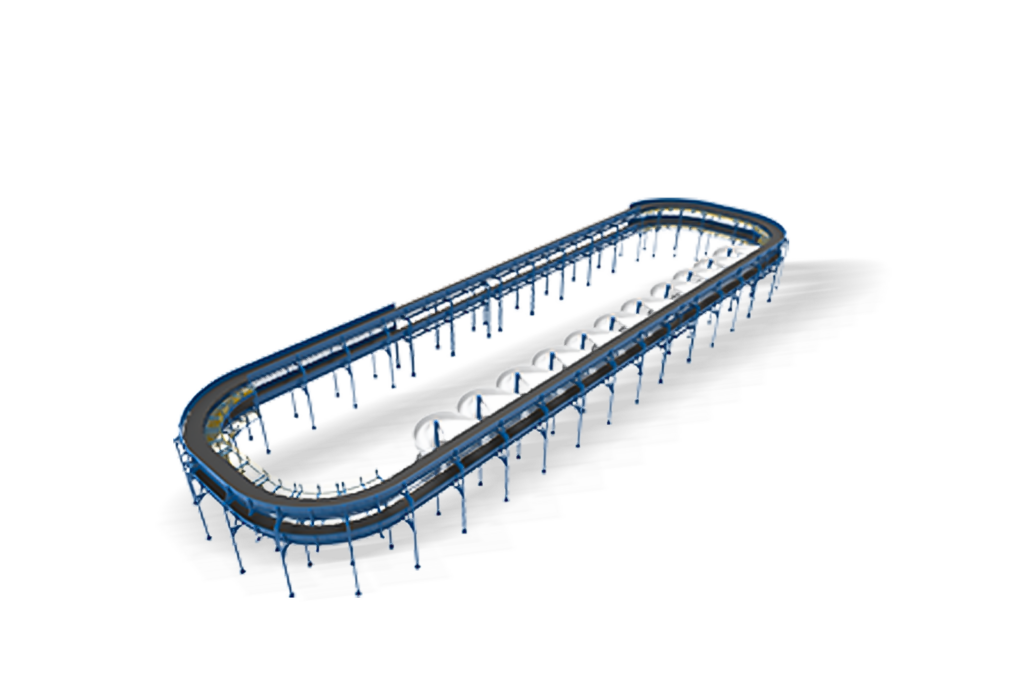

A cross belt sorter system consists of a series of independently controlled conveyor belts mounted perpendicular to the main conveyor line. Each individual belt, or carrier, is equipped with a high-friction surface that can securely hold and transport items of various sizes and shapes. As items enter the system, they are placed on a carrier and transported along the main conveyor until they reach their designated sorting location. At this point, the carrier’s belt activates, swiftly and gently diverting the item onto the appropriate outbound conveyor or chute.

Investing in a high speed cross belt sorter offers numerous benefits for businesses dealing with high-volume sorting operations. Cross belt sorters can handle up to 20,000 items per hour, depending on the specific model and configuration, making them ideal for high-volume applications. The smooth, precise diverting action of the cross belts ensures that items are handled gently, minimising the risk of damage to even fragile or irregularly shaped products. These systems can sort a wide variety of items, from small envelopes and polybags to larger packages and even totes, without the need for manual intervention or adjustments. Vertical cross belt sorters optimise space utilisation by using multiple levels of sorting tracks, allowing for high-capacity sorting in a relatively small area. Cross belt sorter systems can be easily expanded or reconfigured to accommodate growth or changes in your operation, protecting your investment over time.

Cross belt sorter systems are well-suited for a variety of industries and applications, including e-commerce order fulfilment, retail distribution centres, postal and parcel handling, pharmaceutical and medical supply distribution, and third-party logistics (3PL) providers.

When considering a high speed cross belt sorter for your facility, it’s essential to work with an experienced and reputable vendor who can assess your unique requirements and design a customised solution. Key factors to consider include throughput requirements, item characteristics (size, weight, shape, and material), facility layout and available space, integration with existing systems and processes, and maintenance and support needs. By carefully evaluating these factors and selecting a high-quality cross belt sorter system, you can streamline your sorting operation, boost efficiency, and improve overall customer satisfaction.

RELATED: Cross Belt Sorters: Orchestrating Efficient Order Fulfillment

Frequently Asked Questions (FAQs)

- What is the maximum item size that a cross belt sorter can handle?

The maximum item size depends on the specific model and configuration of the sorter. Generally, cross belt sorters can handle items up to 1,200 mm in length, 800 mm in width, and 800 mm in height. - How does a cross belt sorter achieve such high throughput rates?

High speed cross belt sorters achieve high throughput rates through a combination of fast conveyor speeds, efficient item tracking and control systems, and the ability to sort items to multiple destinations simultaneously. - Can a cross belt sorter handle items with irregular shapes or loose packaging?

Yes, the high-friction belts and gentle diverting action of cross belt sorters make them well-suited for handling irregularly shaped items and those with loose packaging, such as polybags. - How does a vertical cross belt sorter differ from a traditional cross belt sorter?

A vertical cross belt sorter uses multiple levels of sorting tracks stacked vertically to maximise space utilisation, while a traditional cross belt sorter uses a single level of sorting tracks. This allows vertical sorters to achieve high throughput in a more compact footprint. - What maintenance is required for a cross belt sorter?

Regular maintenance for a cross belt sorter typically includes routine inspections, cleaning, and lubrication of key components, as well as prompt repair or replacement of worn or damaged parts. Partnering with a reliable vendor that offers comprehensive maintenance and support services can help ensure optimal system performance and longevity.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out SmartlogitecX sales team for your customised automation solution.