A medical device industry vendor in East China faces the pain points:

1️⃣ Rising Volume: Limited space cannot accommodate growing inventory.

2️⃣ Increased SKUs: Hard to meet time-sensitive orders.

3️⃣ Inefficient Picking: High error rates and low efficiency during peak times.

This client is engaged in large-scale R&D and production of medical device products. To address the challenges of increasing business volume, a growing number of SKUs, and low efficiency in manual picking, the Engineering team conducted an on-site survey. Based on various factors such as warehouse space layout, floor load-bearing capacity, overall efficiency, and comprehensive cost-effectiveness, they implemented a shuttle-based dense storage system. This system maximised the use of warehouse space, meeting the client’s need for as many storage positions as possible.

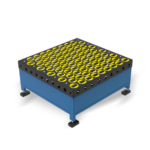

Wayzim introduced core automated handling equipment within the warehouse: the addition of Pallet Four-way shuttles has greatly enhanced the client’s warehouse operation efficiency and accuracy!

This product integrates Four-way movements, instant direction change, automatic handling, intelligent monitoring, and dynamic traffic management, with the following standout features:

Features

-Positioning accuracy: ±2 mm;

-Positioning mode: QR code/RFID + photoelectric navigation;

-Rated load: 1500 kg.

Related: Pallet Four-way Shuttle: Optimising Warehouse Operations with Intelligence and Efficiency

Key technologies

-Travel Positioning Technology;

-Safety Technology;

-Power Battery Technology;

-Automatic Charging Technology;

Pallet Four-way shuttle is widely used in industries with diverse SKUs but large quantities of single items, such as the food, fruit and vegetable, beverage, chemical, and tobacco industries, thanks to its excellent performance and advanced product technology.

What benefits and strengths has the Four-way shuttle dense storage system brought to its clients?

The project was designed with over 3,000 storage positions, capable of storing more than 50,000 boxes of goods, with an inbound and outbound efficiency of up to 60 pallets per hour. This significantly improved warehouse operation efficiency and accuracy, ensuring order fulfillment speed and accuracy while saving the client millions of dollars annually in external warehouse rental costs.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.