Automated Conveyor Systems

- Home

- Automated Conveyor Systems

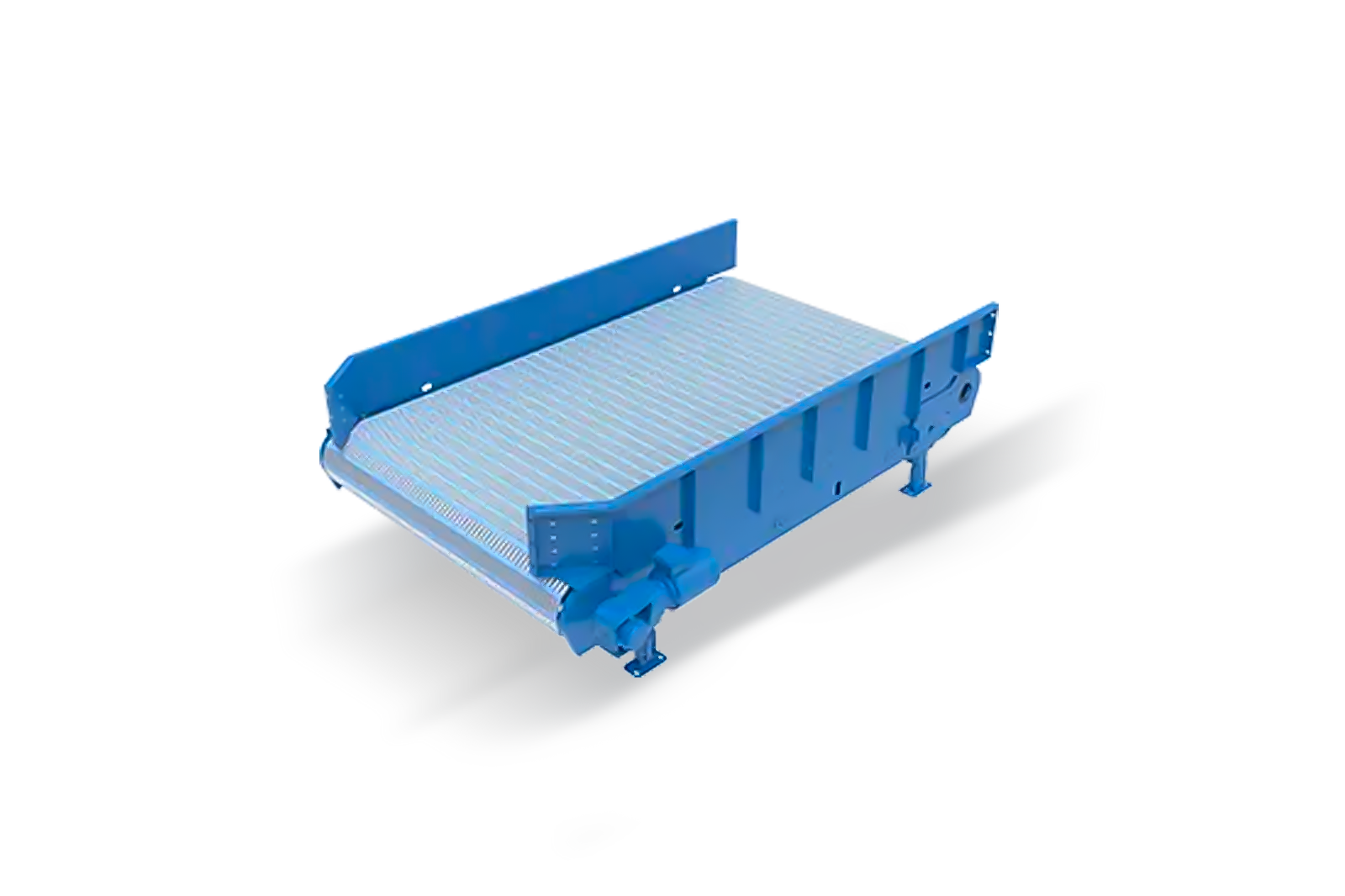

Belt conveyor

Modular Conveyor

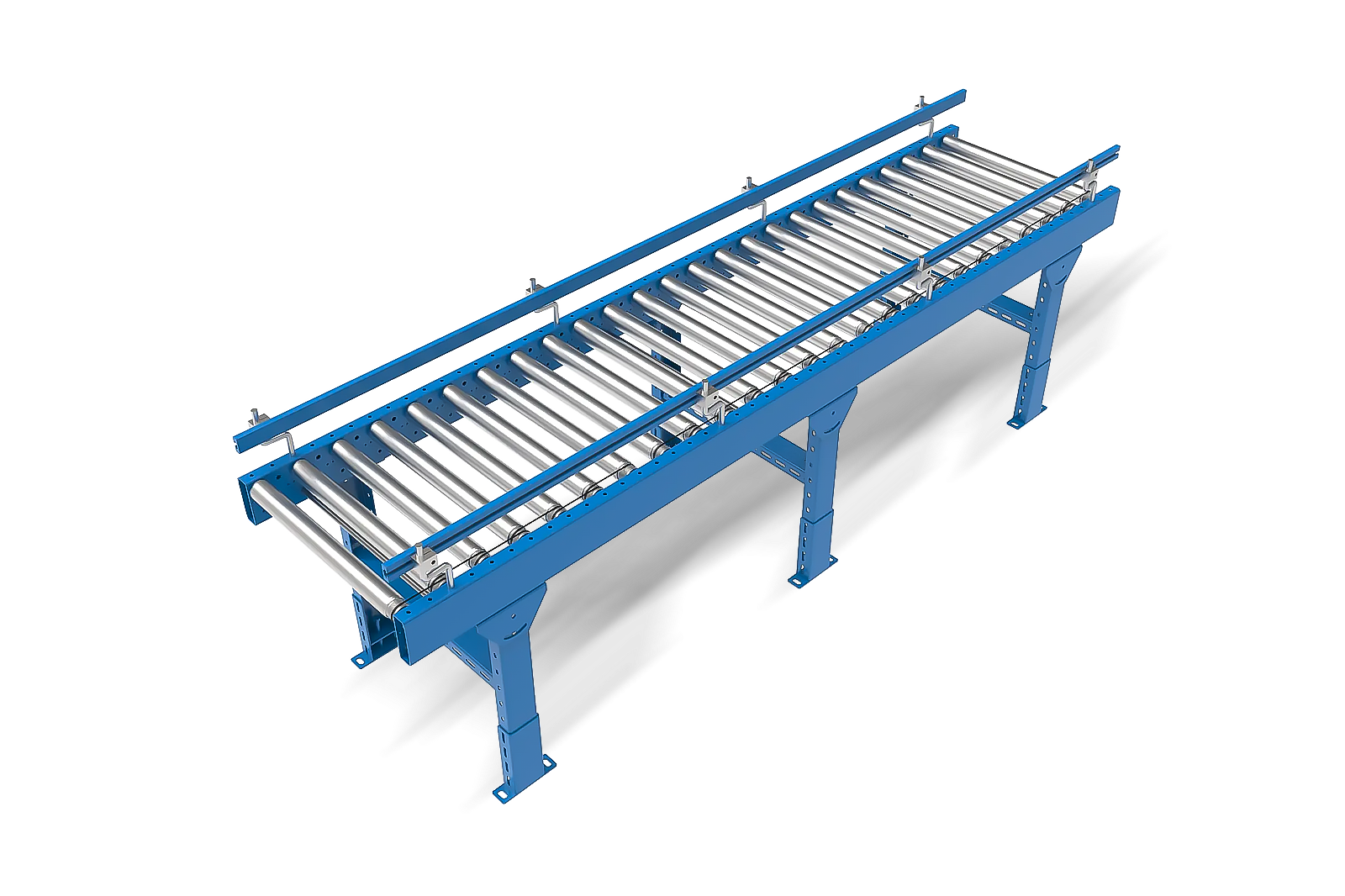

Pallet Roller Conveyor

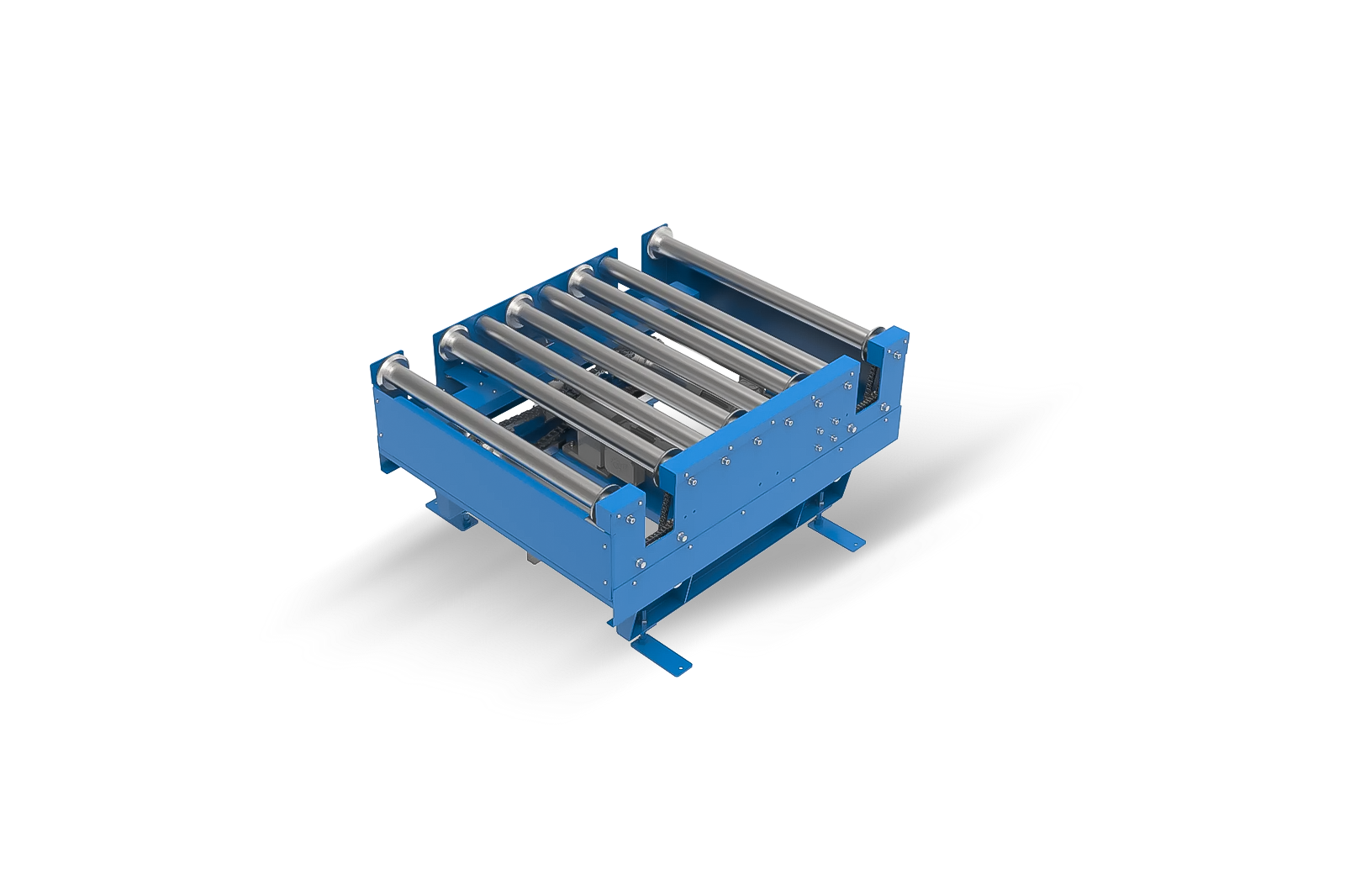

Tote Roller Conveyor

Pop-up Sorter

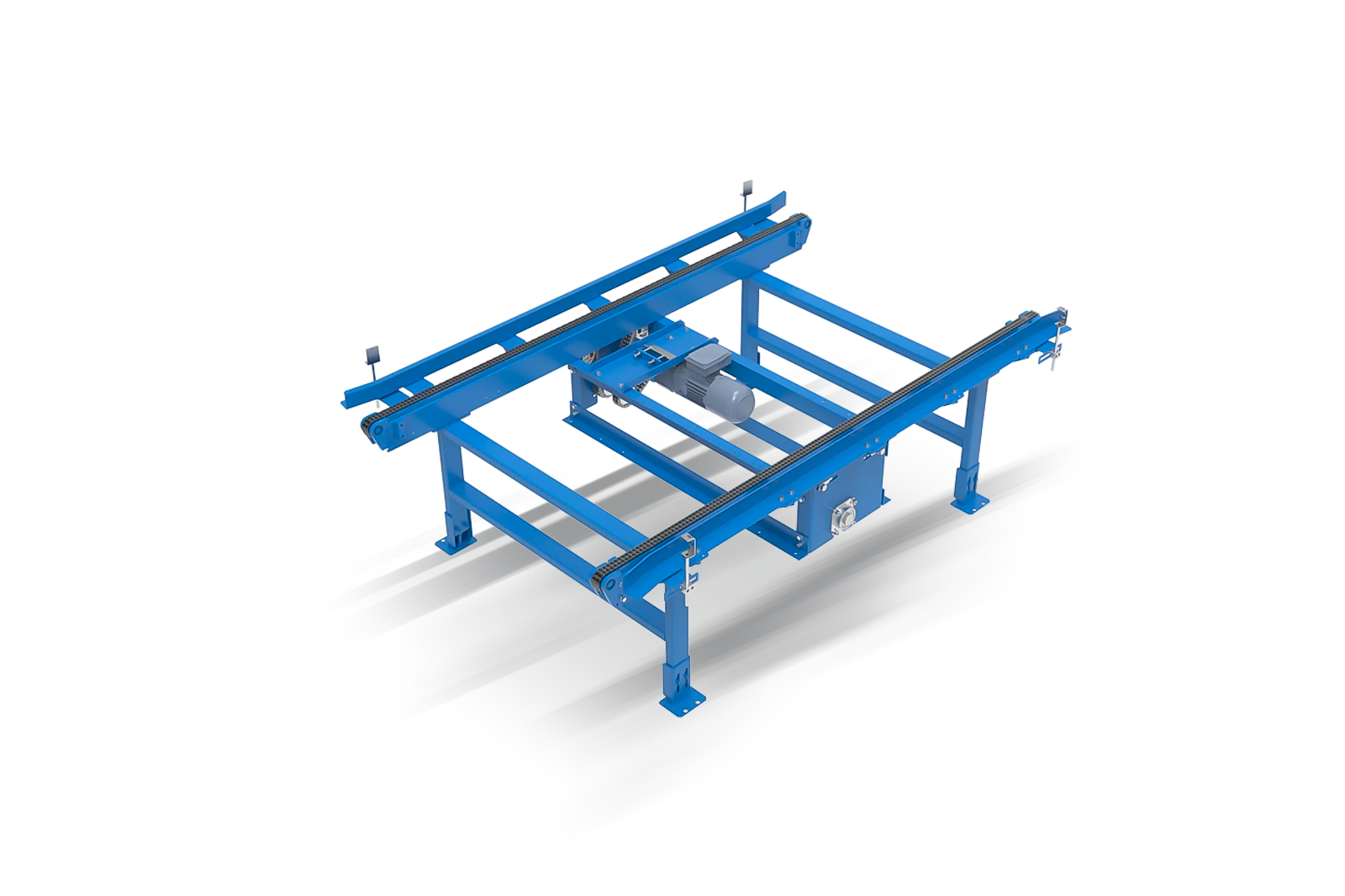

Chain conveyor

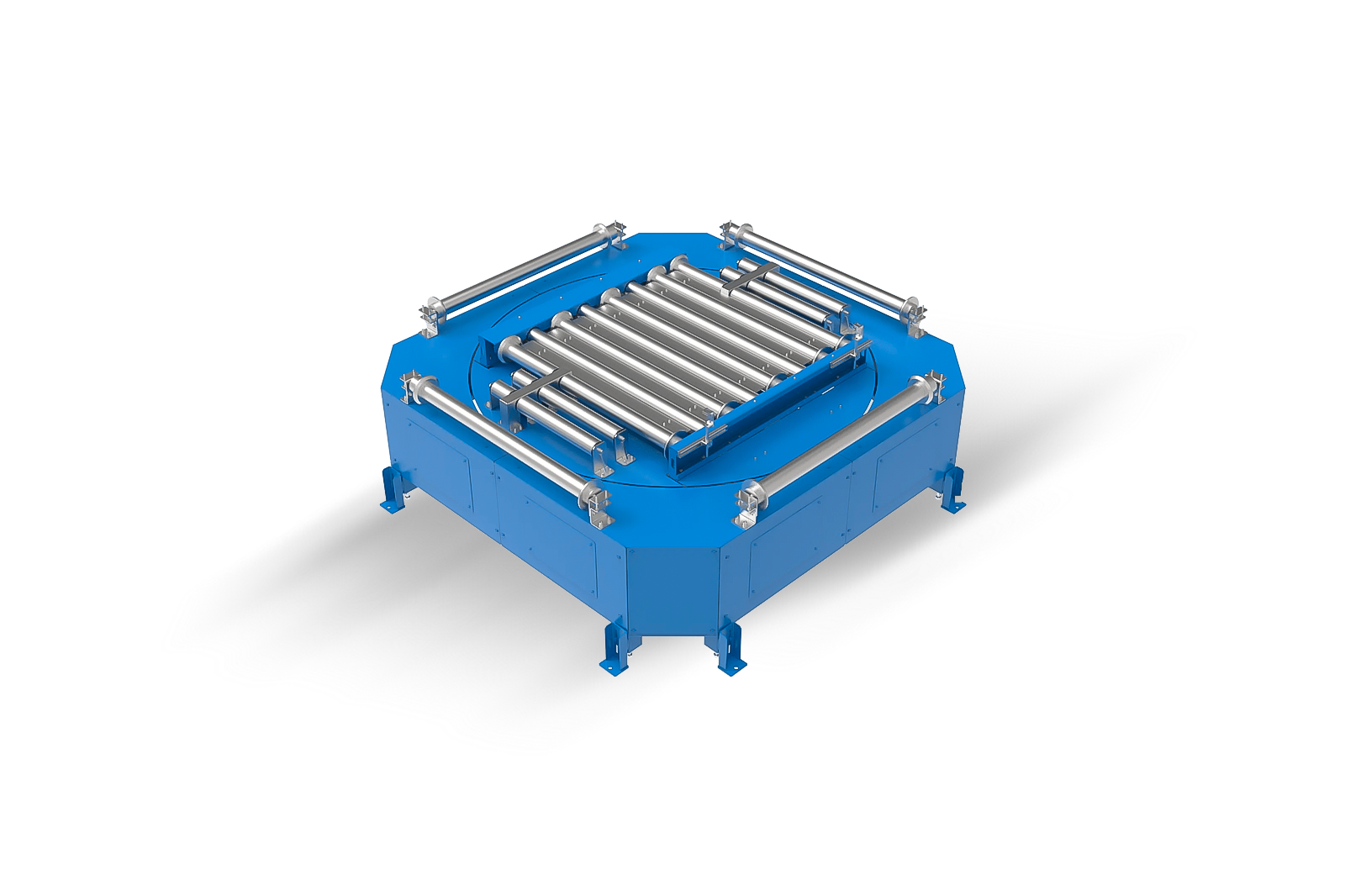

Turntable

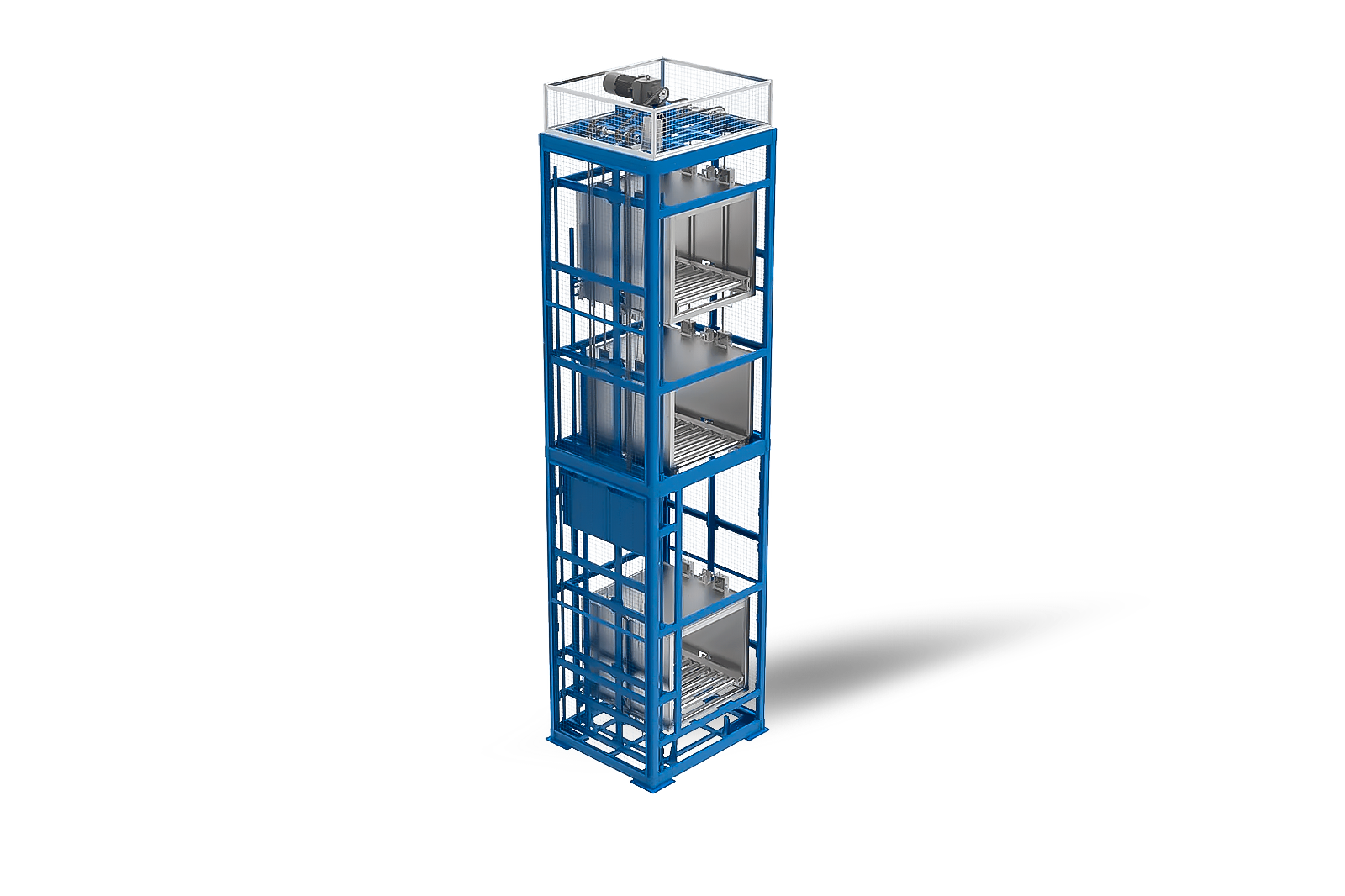

Continuous Vertical Conveyor

Manual Forklift

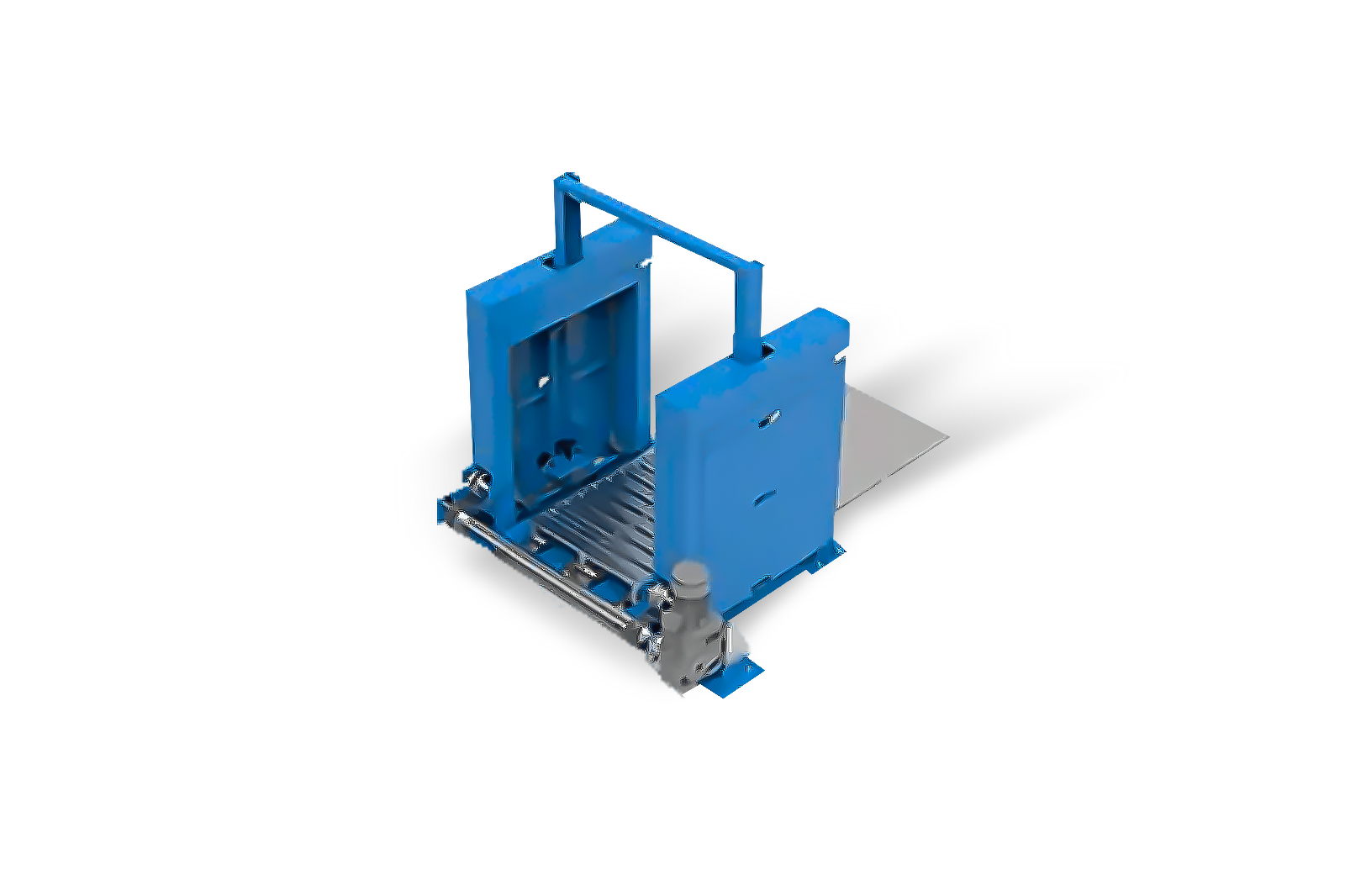

Reciprocating Vertical Conveyor

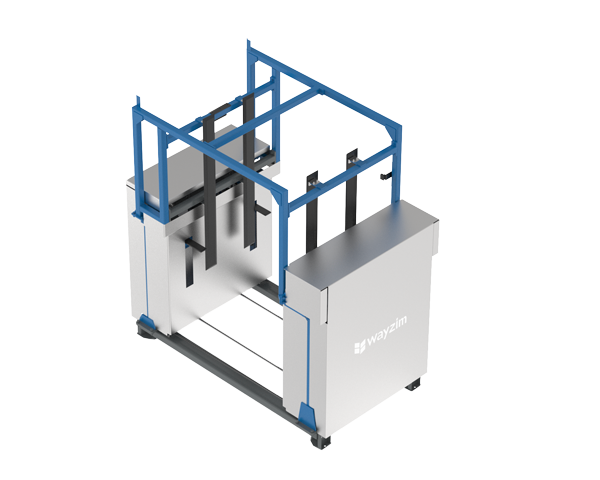

Unstacker/Stacker

Modular Belt Conveyor

Divert Roller Conveyor

Curve Roller Conveyor

Edge Roller Conveyor

Automated Conveyor Systems

In the realm of modern logistics, the significance of efficient material handling cannot be overstated. At SmartLogitecX, we understand this necessity and bring to you a range of Automated Conveyor Systems, designed to enhance the efficency and streamline the operations of your business. Our systems are not just a series of mechanical components; they are the backbone of efficient warehouses, manufacturing units, and distribution centres.

Innovative Design Meets Functionality

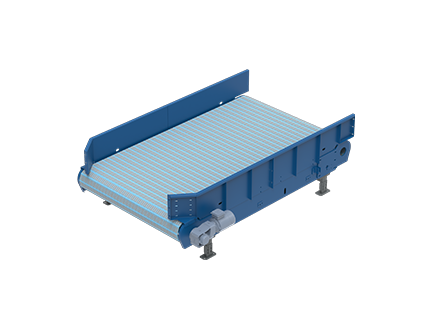

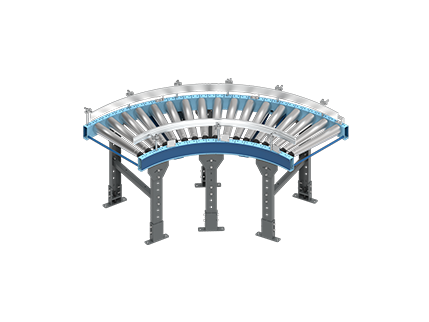

Our Automated Conveyor Systems stand out with their innovative design and functional excellence. We offer a variety of systems such as Belt Conveyors, Modular Conveyors, and Curve Roller Conveyors, each tailored to meet specific industrial needs. The Belt Conveyor, a fundamental component of our system, is celebrated for its reliability and versatility in various operational layouts.

Diverse Range for Diverse Needs

At SmartLogitecX, we recognise the diversity of material handling needs across different industries. That’s why our product range includes specialised systems like the Pallet Roller Conveyor and Tote Roller Conveyor. The Pallet Roller Conveyor is an integral piece of equipment in industries such as manufacturing and construction, renowned for improving productivity and reducing labor intensity. On the other hand, the Tote Roller Conveyor, with its motorised rollers and zero pressure accumulation, is ideal for scenarios requiring sensitive handling and effective space management.

Key Components of Automated Conveyor Systems

- Belt Conveyor: A staple in any automated system, the Belt Conveyor offers a reliable and straightforward solution for transporting goods. It’s a versatile component that fits into various operational layouts.

- Modular Conveyor and Curve Roller Conveyor: These conveyors bring flexibility to the table. Modular designs allow for easy customisation, while Curve Roller Conveyors make navigating corners seamless.

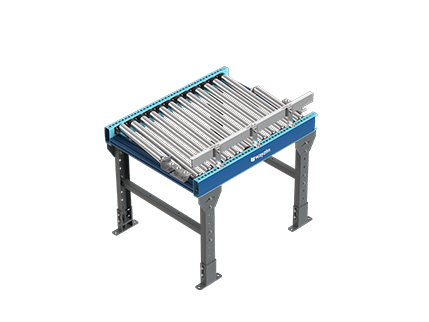

- Divert and Tote Roller Conveyors: Specialising in sorting and accumulation, these conveyors are crucial for managing the flow of goods, ensuring that each item reaches its intended destination without hassle.

- Pallet Roller Conveyor: Tailored for heavier loads, this conveyor is essential in industries where large and heavy items are the norm, such as construction materials and heavy manufacturing.

- Chain Conveyor and Continuous Vertical Conveyor: These systems are ideal for situations where items need to move vertically or in unique patterns, proving their worth in complex logistics setups.

- Turntable and Pop-Up Sorter: Adding flexibility to the conveyor system, these components are vital for changing the direction of goods and sorting them efficiently.

- Reciprocating Vertical Conveyor and Manual Forklift: These are perfect for multi-level operations, ensuring seamless transition of goods between different heights and floors.

Customisation and Flexibility

Our Divert Roller Conveyor and Edge Roller Conveyor embody customisation and flexibility. The Divert Roller Conveyor, equipped with motorised rollers and a V-ribbed belt drive, is perfect for sorting and diverting materials in a logistic setup. The Edge Roller Conveyor, with its diagonal material conveying capability, is essential in operations requiring precise material alignment and packaging.

Advanced Handling with Chain and Continuous Vertical Conveyors

For more complex logistic scenarios, our Chain Conveyor and Continuous Vertical Conveyor offer advanced solutions. The Chain Conveyor, using pallets and totes as carriers, is a staple in automated logistics systems, while the Continuous Vertical Conveyor is ideal for unidirectional vertical movement of goods, offering high handling capacity and reliability.

Enhancing Operations with Smart Solutions

Further enhancing our range are the Turntable, Pop-up Transfer Sorter, and Vertical Reciprocating Conveyor. The Turntable facilitates the directional movement of large totes and pallets, while the Pop-up Transfer Sorter, a blend of cam-linkage and roller-chain mechanisms, efficiently handles material sorting and direction change. The Vertical Reciprocating Conveyor, capable of handling diverse item sizes and weights, is a testament to our commitment to versatile and efficient design.

Maximising Space and Efficiency

Understanding the need for space optimisation, our Unstacker/Stacker is designed for efficient pallet handling in automated warehouses, significantly improving space utilisation. Additionally, the Manual Forklift offers a practical solution for height-adjusted material handling, bridging the gap between the ground and conveyor lines.

A Step Towards Smarter Logistics

Automated Conveyor Systems are not just products; they are a step towards smarter, more efficient logistics and material handling. With our commitment to innovation, quality, and customer satisfaction, we aim to redefine the standards of logistics automation. Join us in embracing the future of material handling with SmartLogitecX’s Automated Conveyor Systems, where efficiency, reliability, and innovation converge to transform your logistic operations.

Benefits of Automation

for forward-thinking companies

When robots and automation are implemented in a business effectively, they don’t replace jobs. They augment them to drive greater productivity.

- Greater speed

- Increased accuracy

- Increased Warehouse Safety

- Adaptable Workforce

- Innovative Brand Image

- Higher Customer Satisfaction