Warehouse Automation Solutions

- Home

- Warehouse Automation Solutions

Latent AGV

Fork AGV

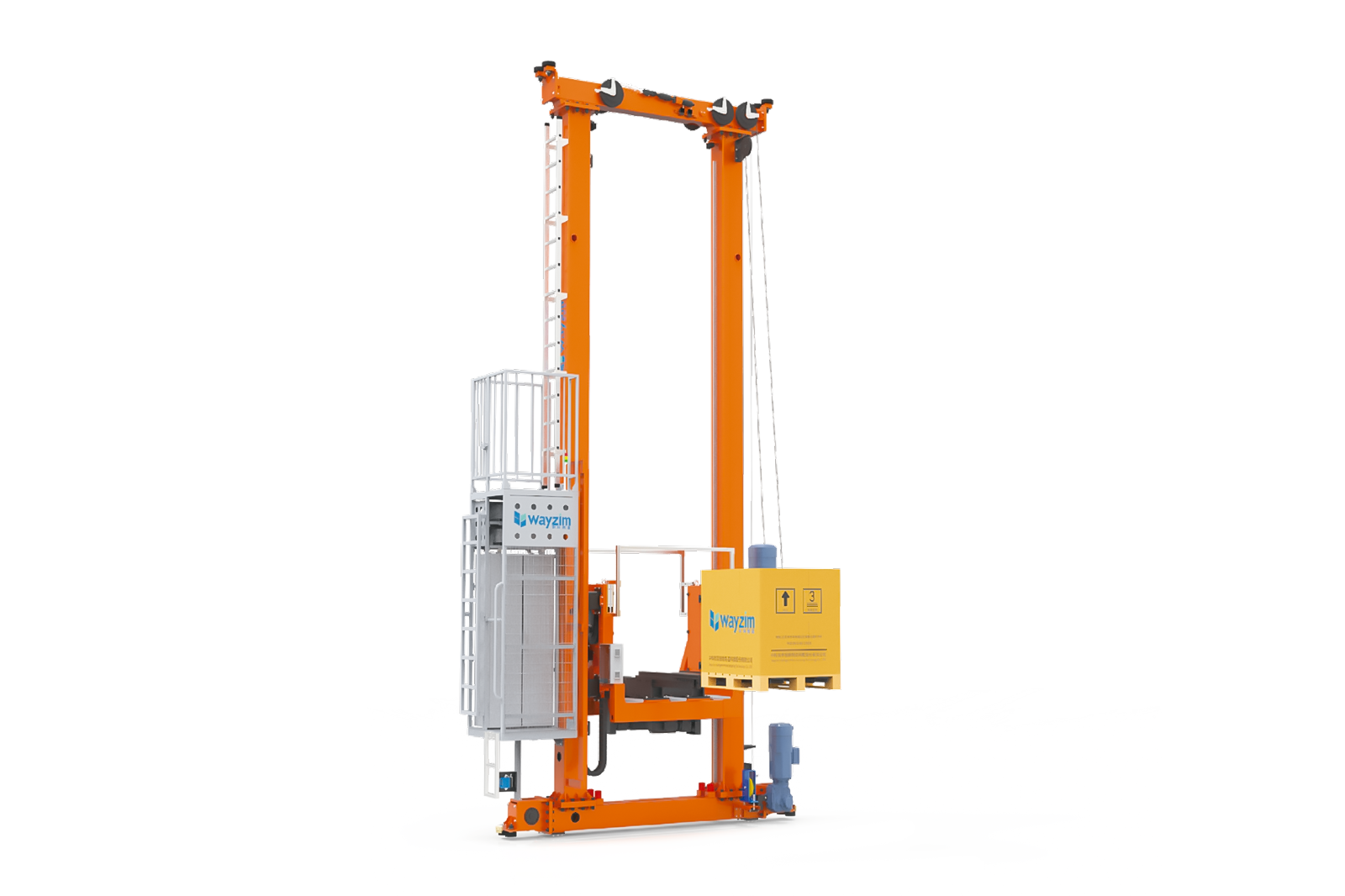

ASRS Pallet Stacker Crane

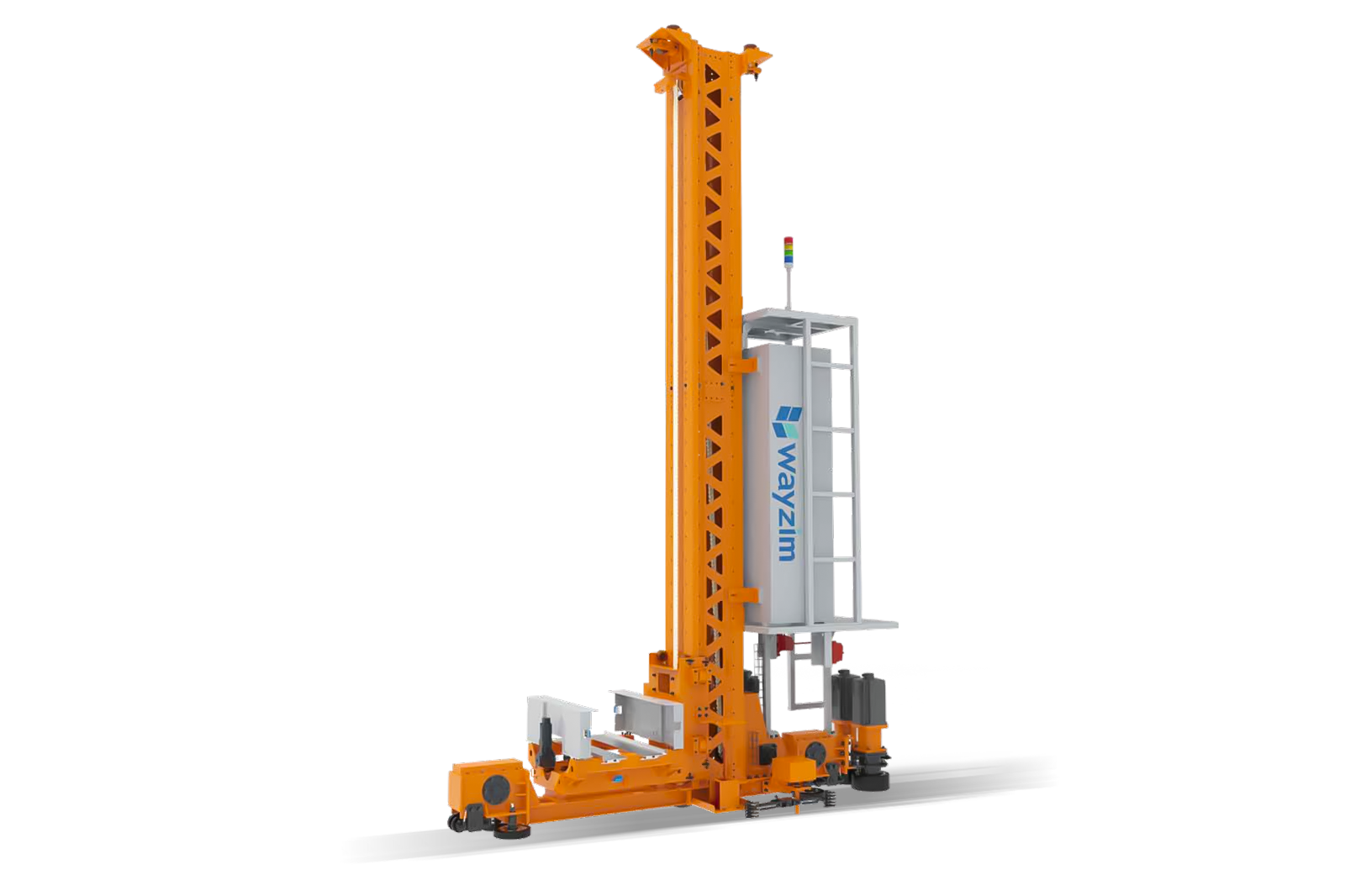

Tote Stacker Crane

Pallet Four – Way Shuttle

Tote Four-way Shuttle

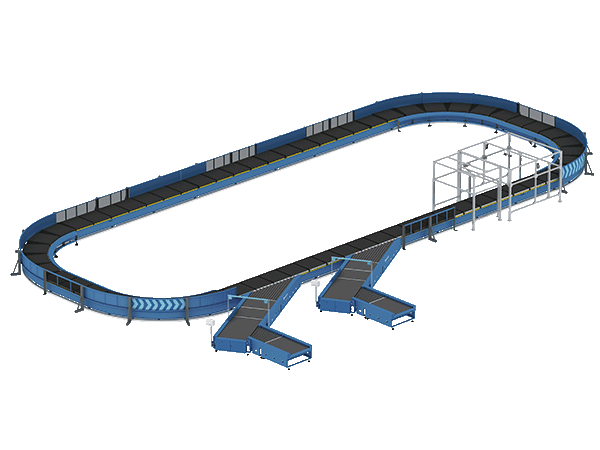

Cross Belt Sorter

Linear Sorter

Pivot Wheel Sorter

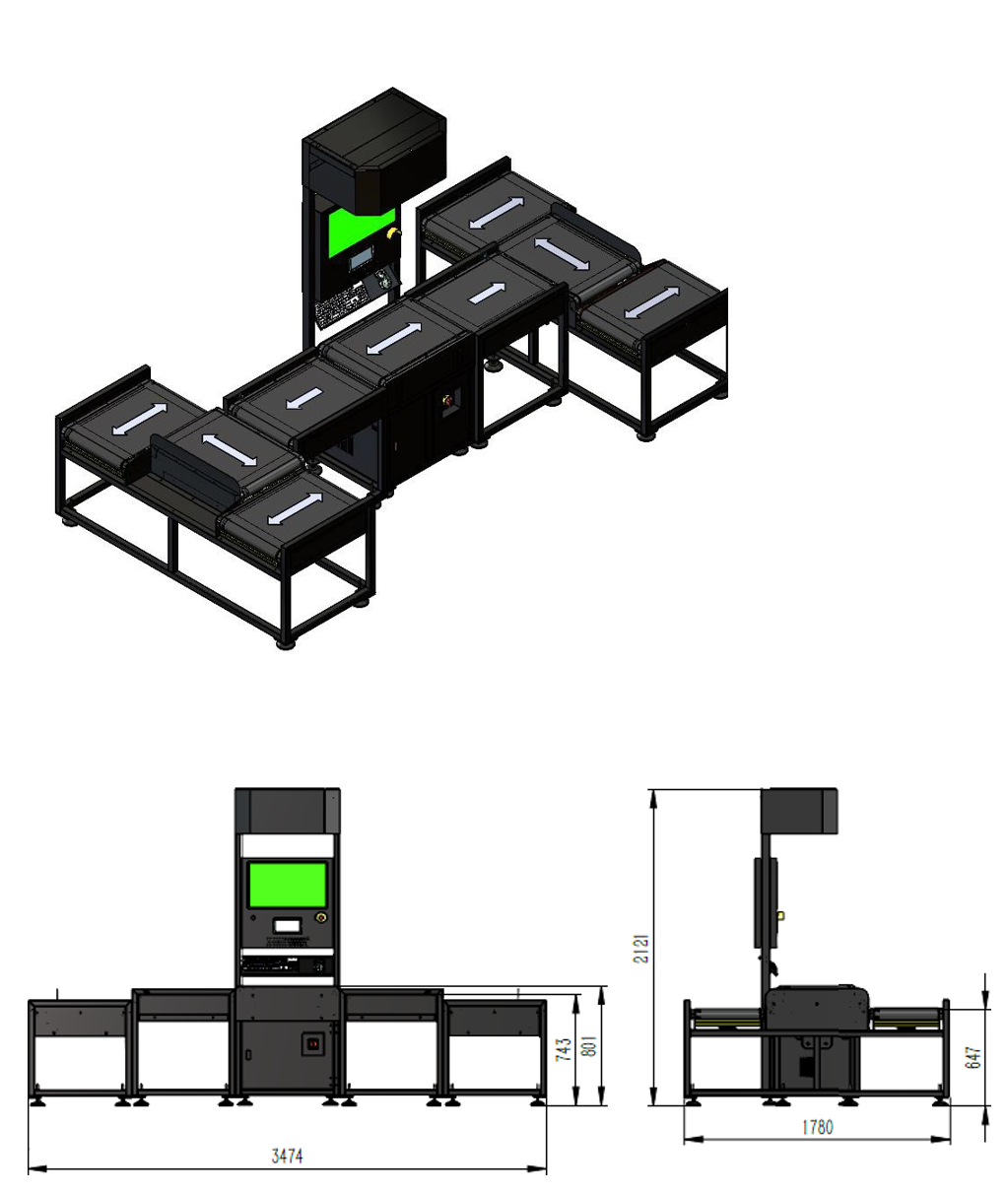

DWS – Dynamic Dimensioning, Weighing and Scanning

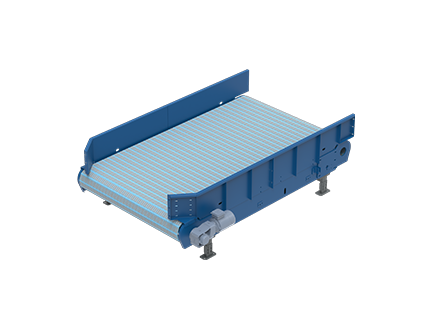

3D Bulk Flow Singulator

Single Piece Separation

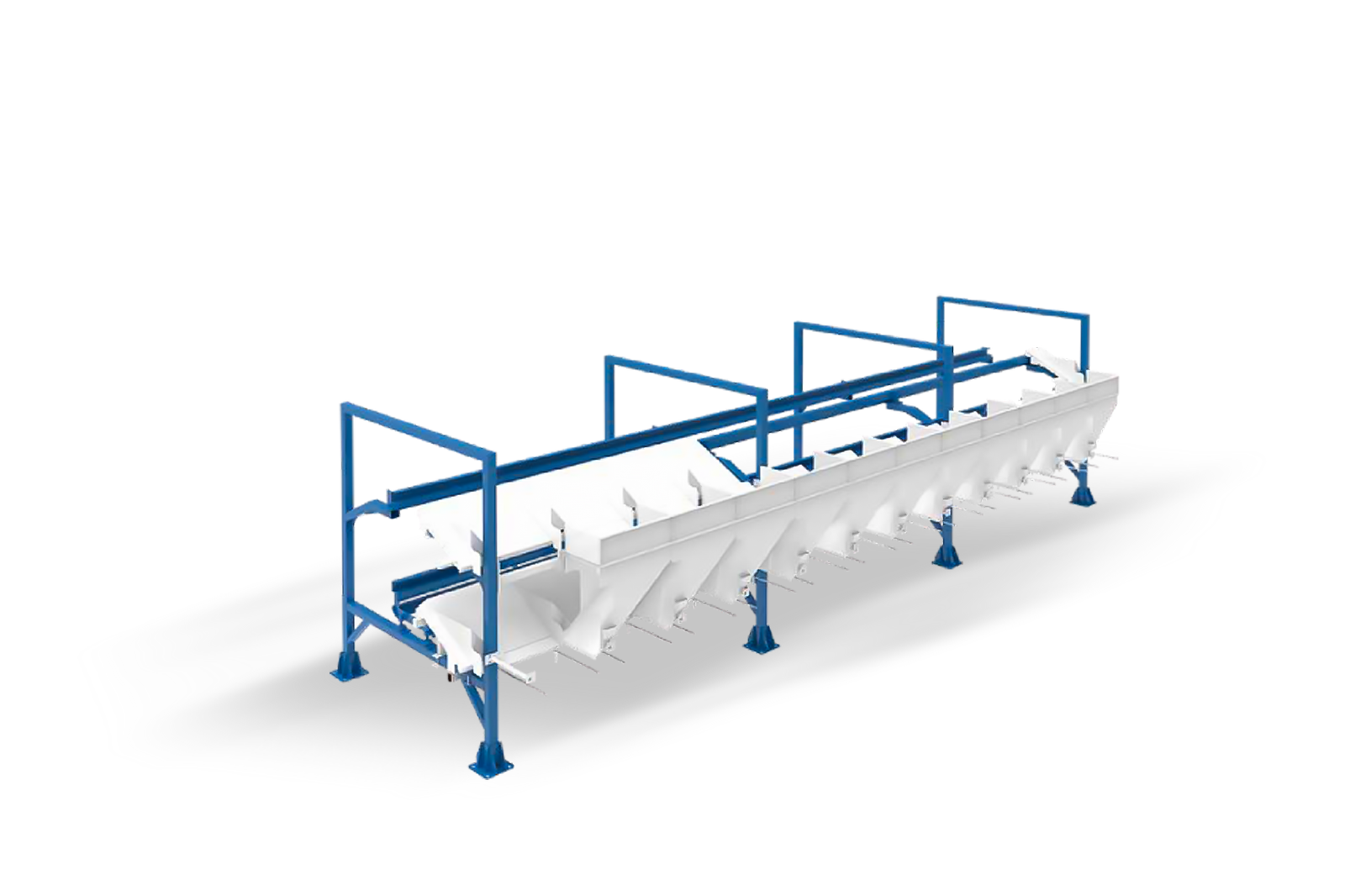

Chute

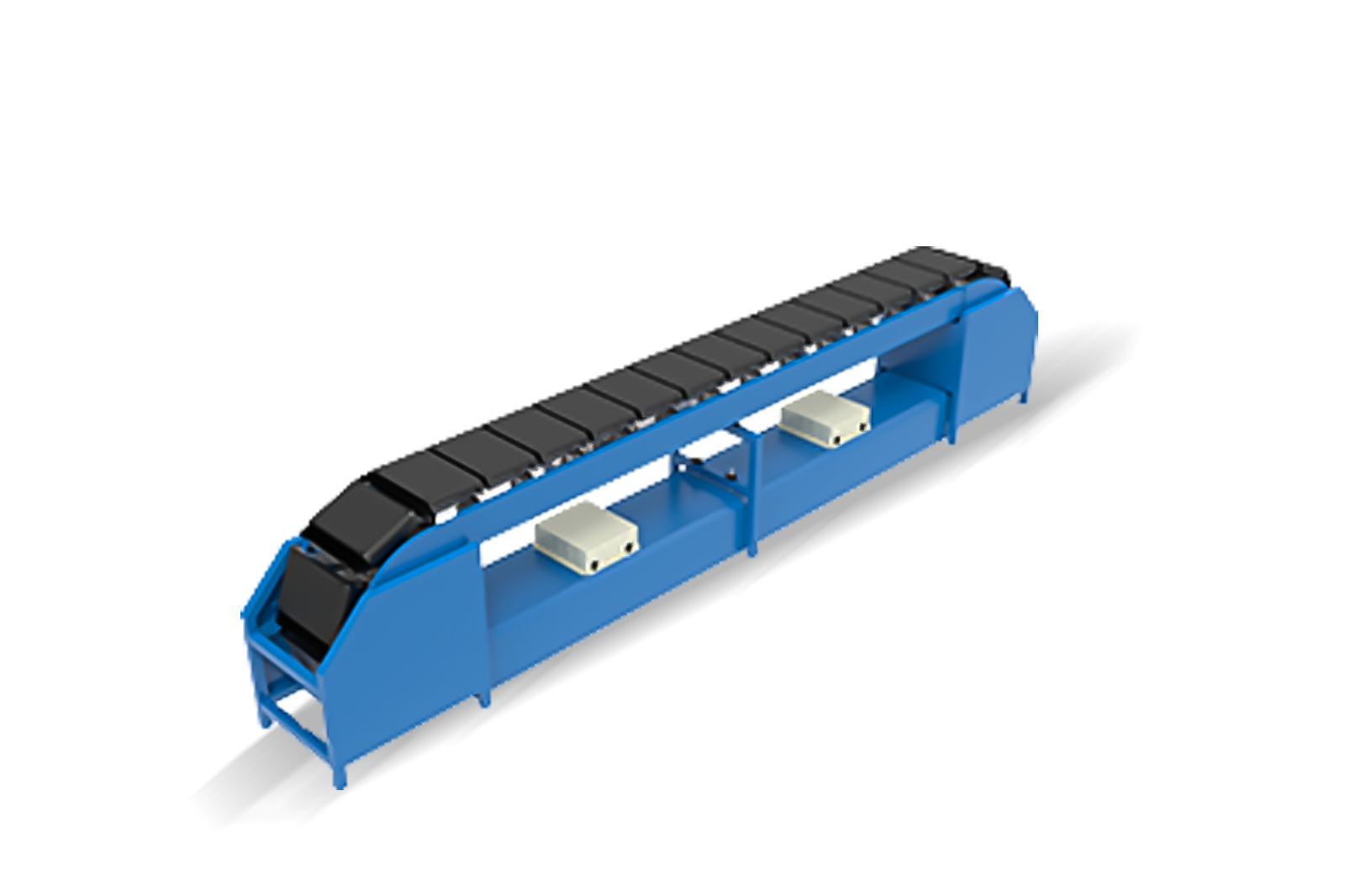

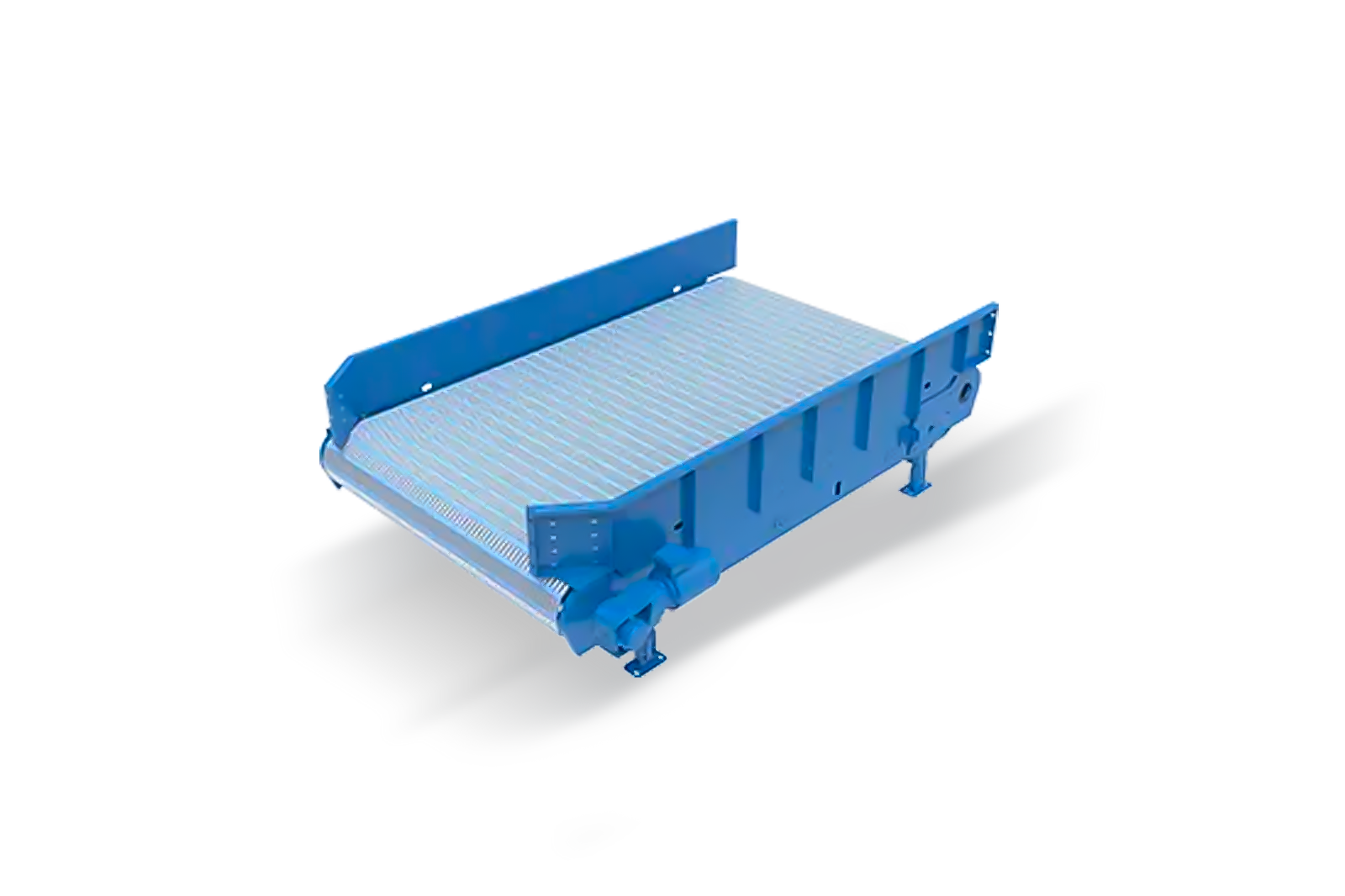

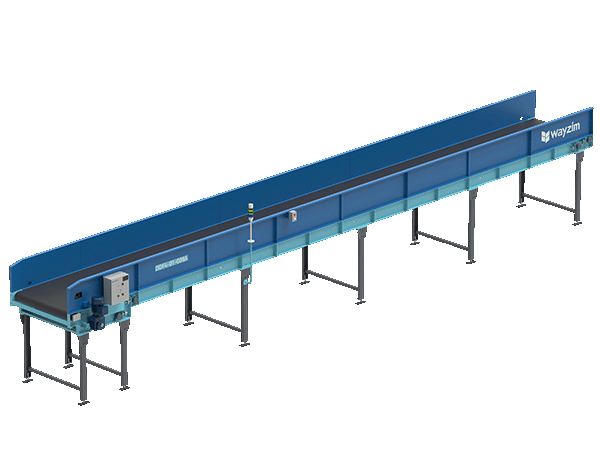

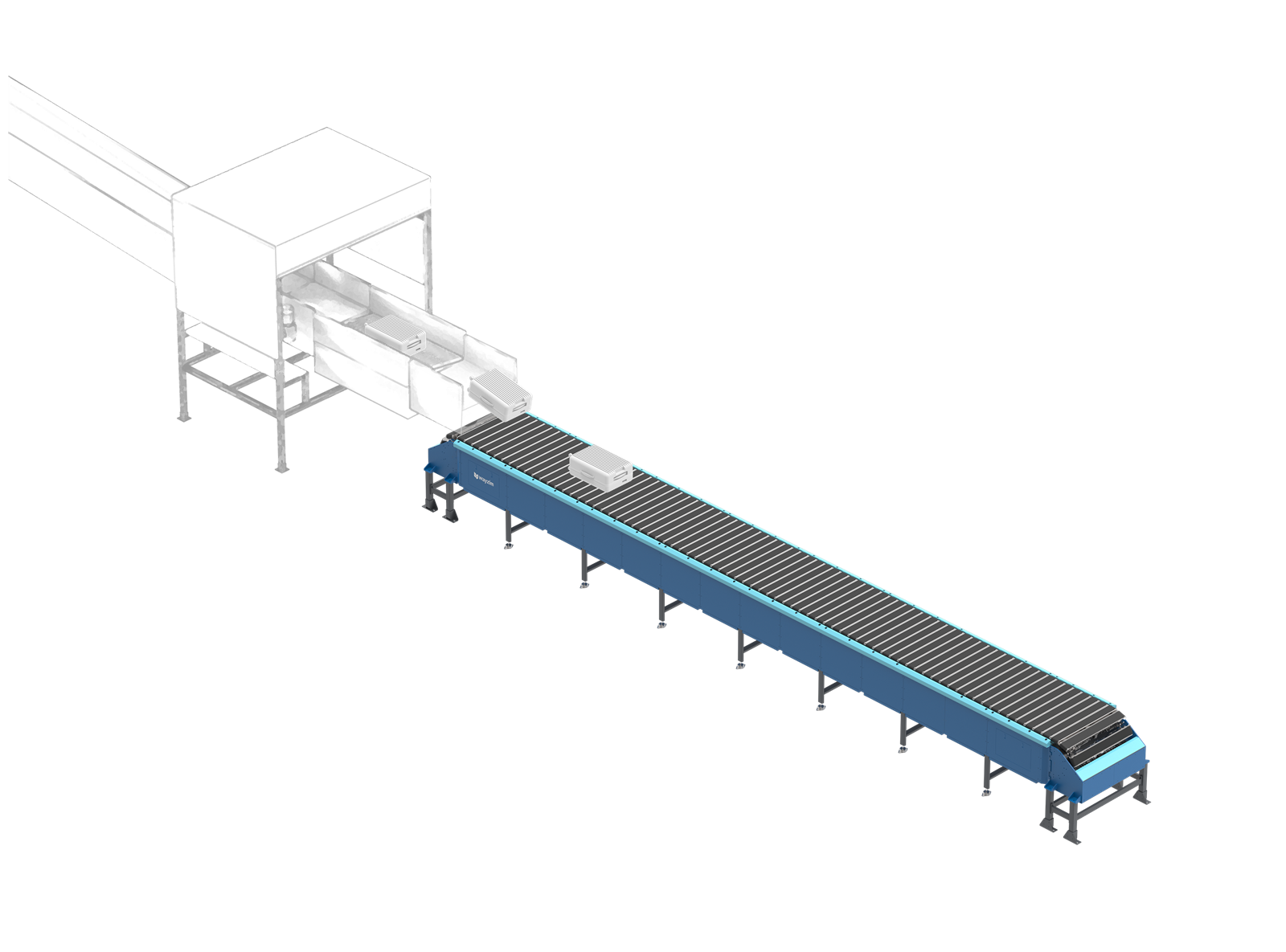

Belt conveyor

Modular Conveyor

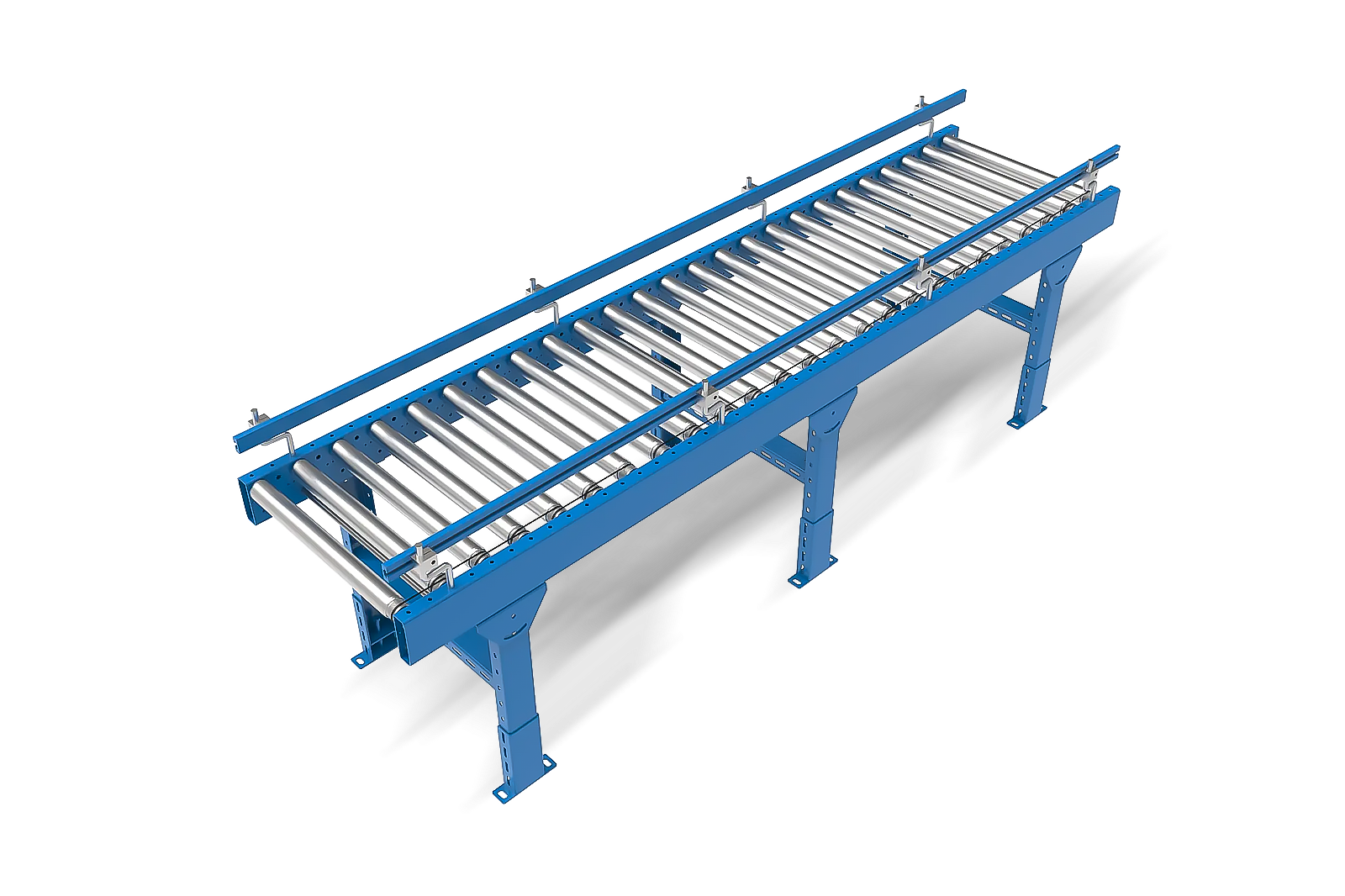

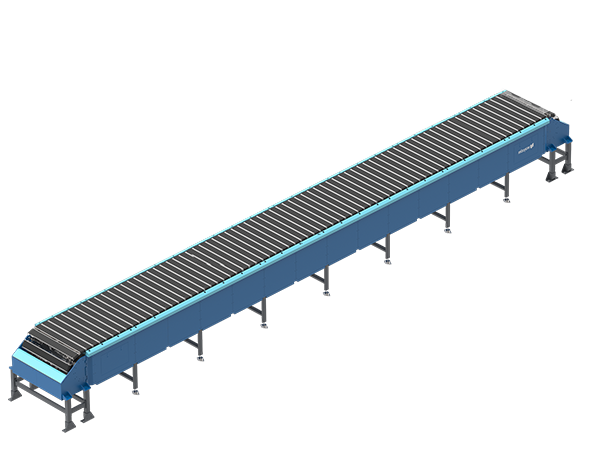

Pallet Roller Conveyor

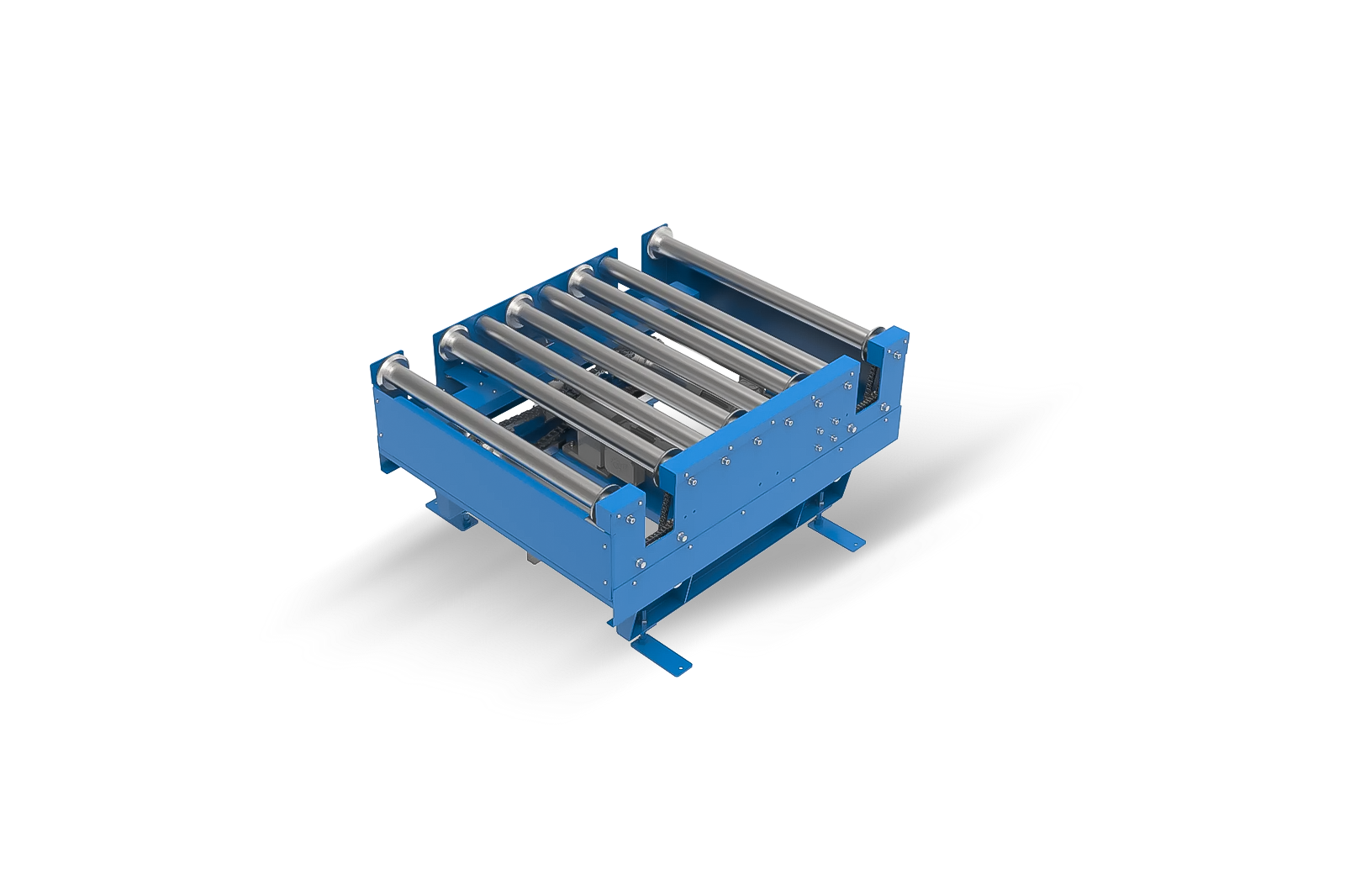

Tote Roller Conveyor

Pop-up Sorter

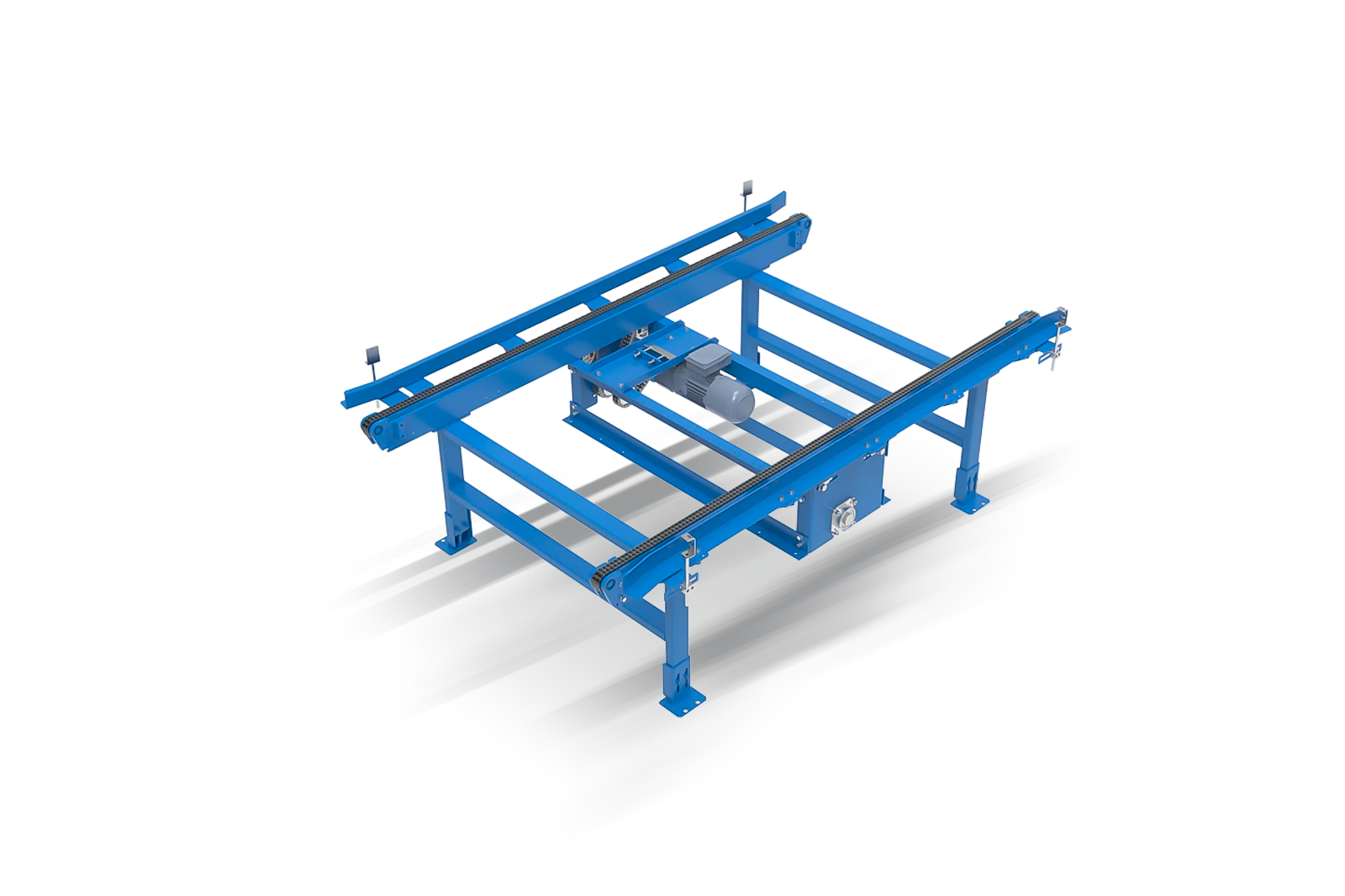

Chain conveyor

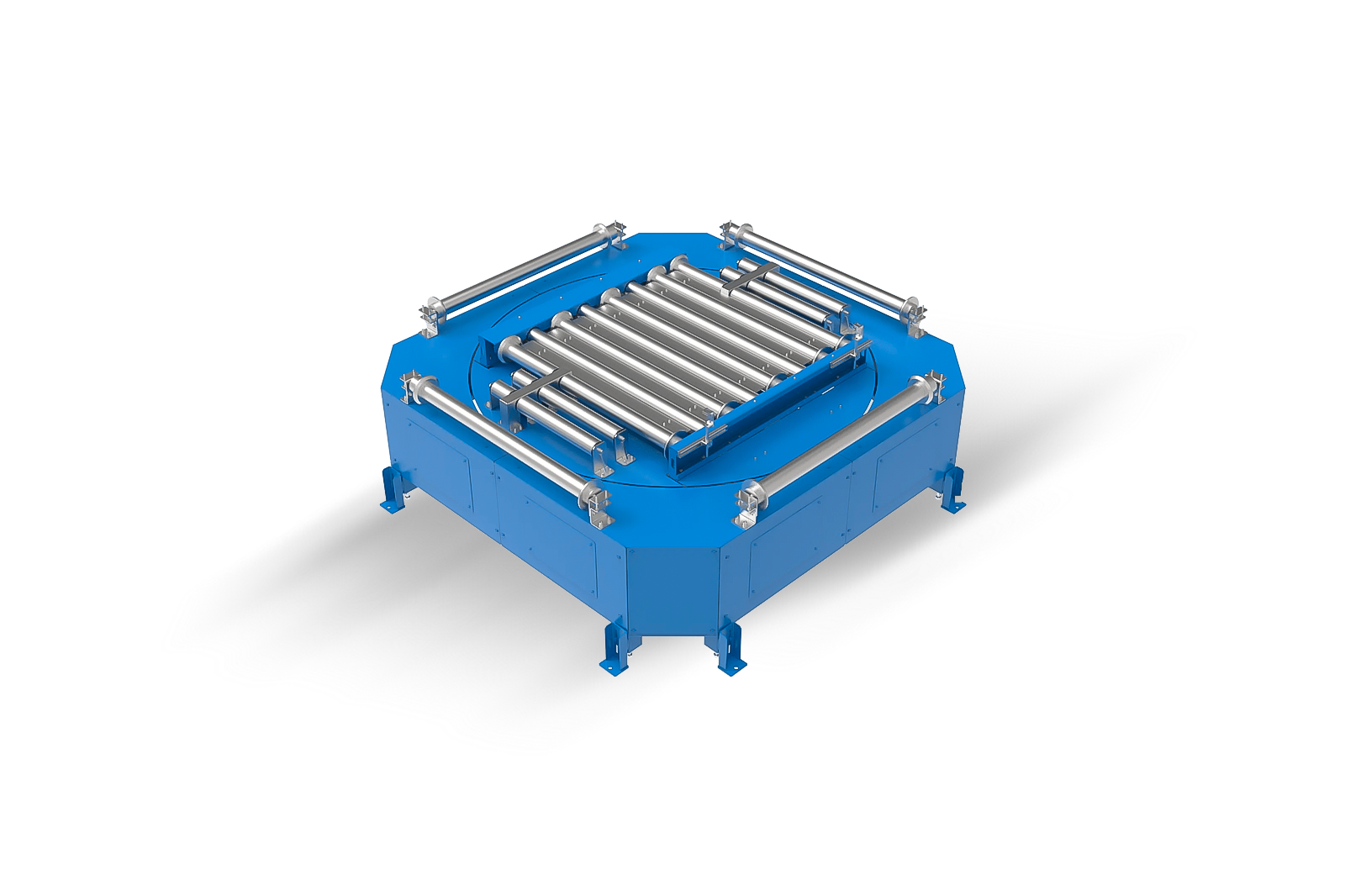

Turntable

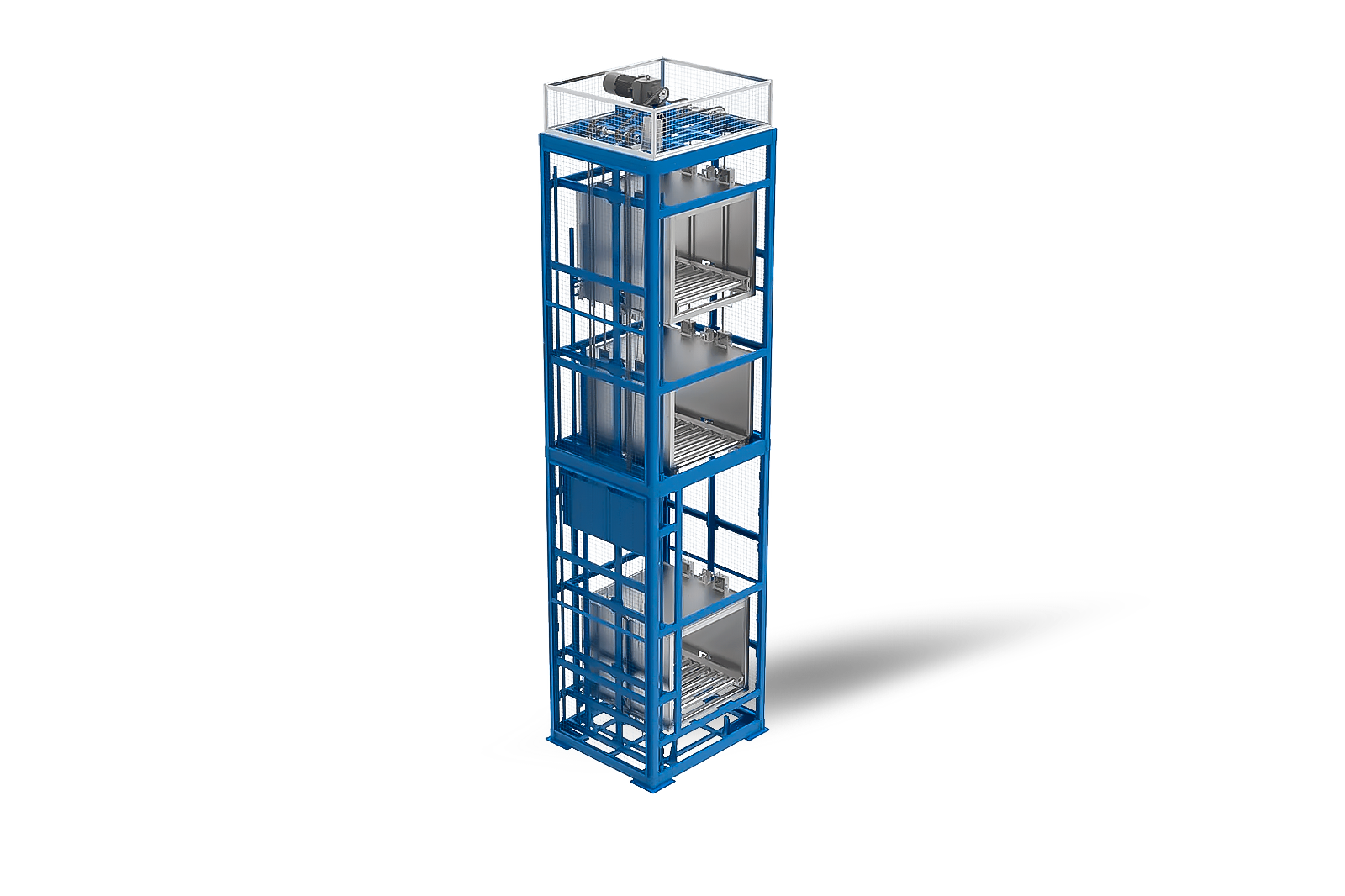

Continuous Vertical Conveyor

Manual Forklift

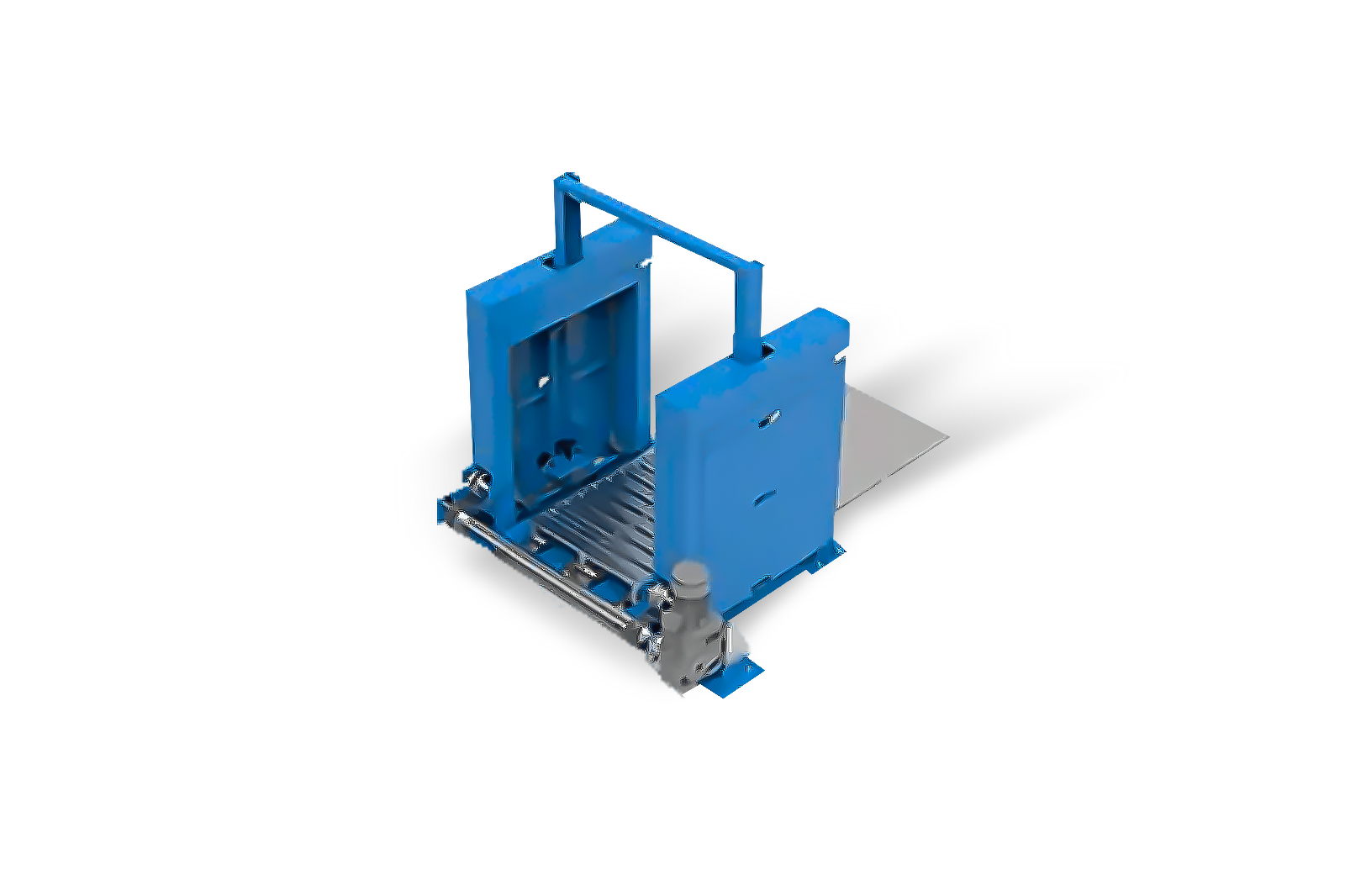

Reciprocating Vertical Conveyor

Narrow Belt Sorter

2D Bulk Flow Singulator

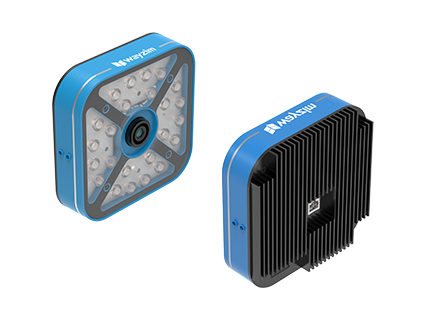

Line Laser Stereo Camera

Laser Speckle Stereo Camera

RGB-D Intelligent Stereo Camera

3D Laser Profile Sensor

Intelligent Line-Scan Camera

Intelligent Area-scan Camera

Position Detection System

Industrial Barcode Reader

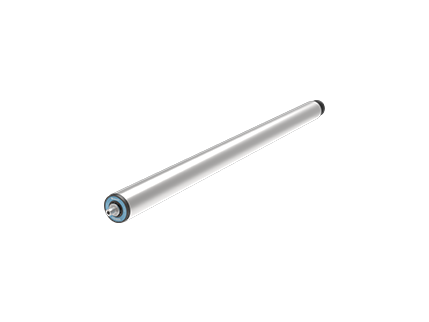

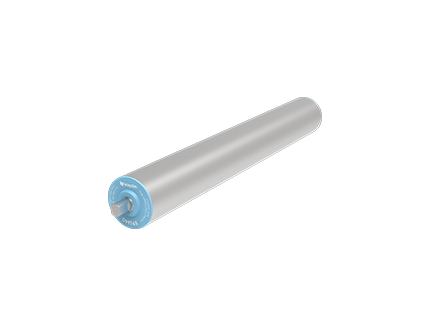

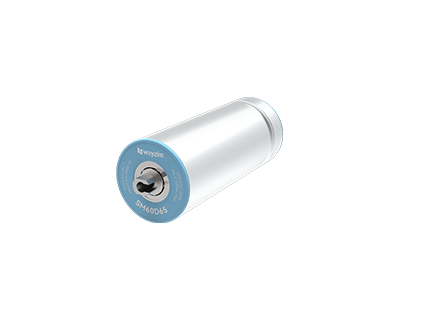

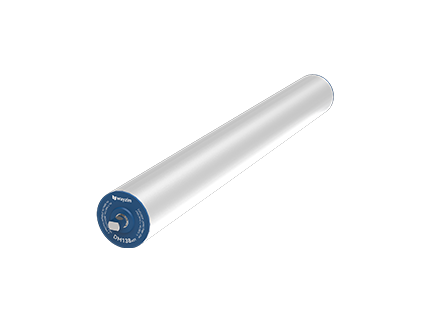

Roller for Intelligent Warehouse Conveyor – MDR50

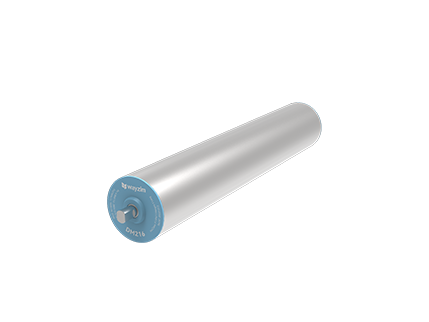

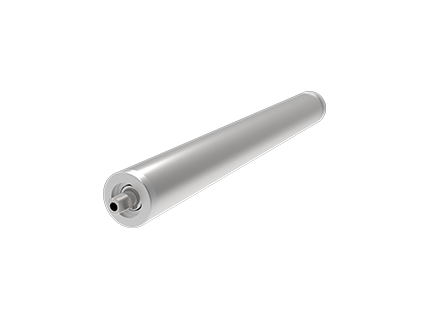

Roller for Belt Conveyor Line – DM165(SYNC/ASYNC)

Roller for Belt Conveyor Line – DM216(SYNC/ASYNC)

Roller for Belt Conveyor Line – DM70

Roller for Belt Conveyor Line – DM100

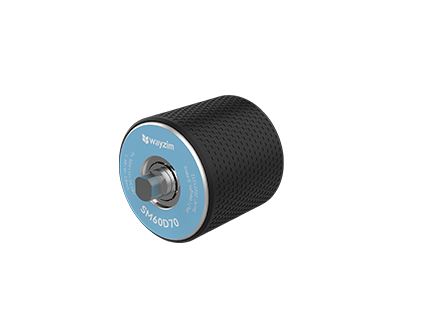

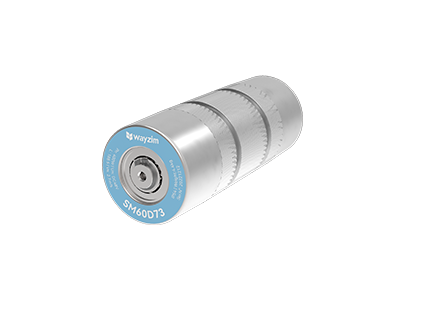

Roller for Pivot Wheel Sorter – SM60

Roller for Narrow-belt Sorter – SM60

Roller for Cross Belt Sorter – SM67

RGV Carrier

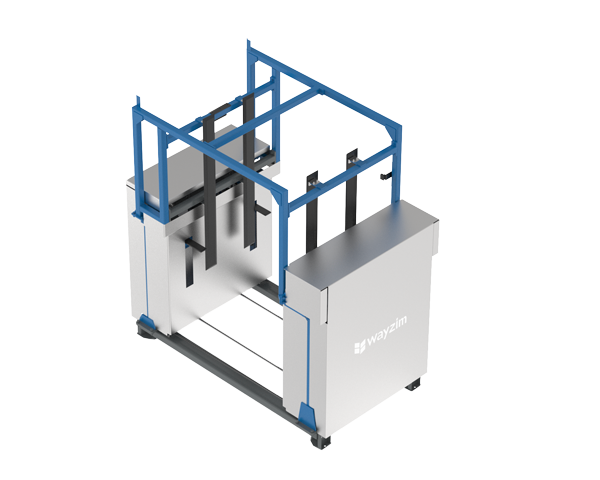

Unstacker/Stacker

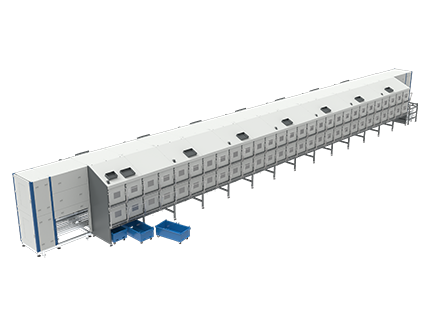

Automated Put Wall

Modular Belt Conveyor

Straight Cross-belt Sorter

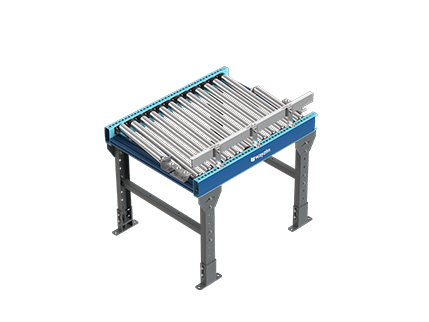

Straight Conveyor

Weighing and Labeling Conveyor

Induction Conveyor

Sorter

Horizontal Pick-up Turntable

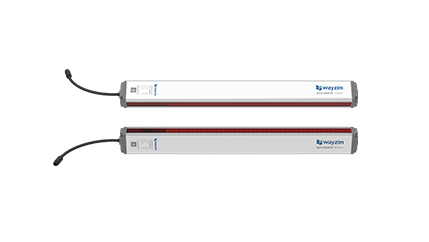

Through-beam Measuring Light Grid

Mini Sorters

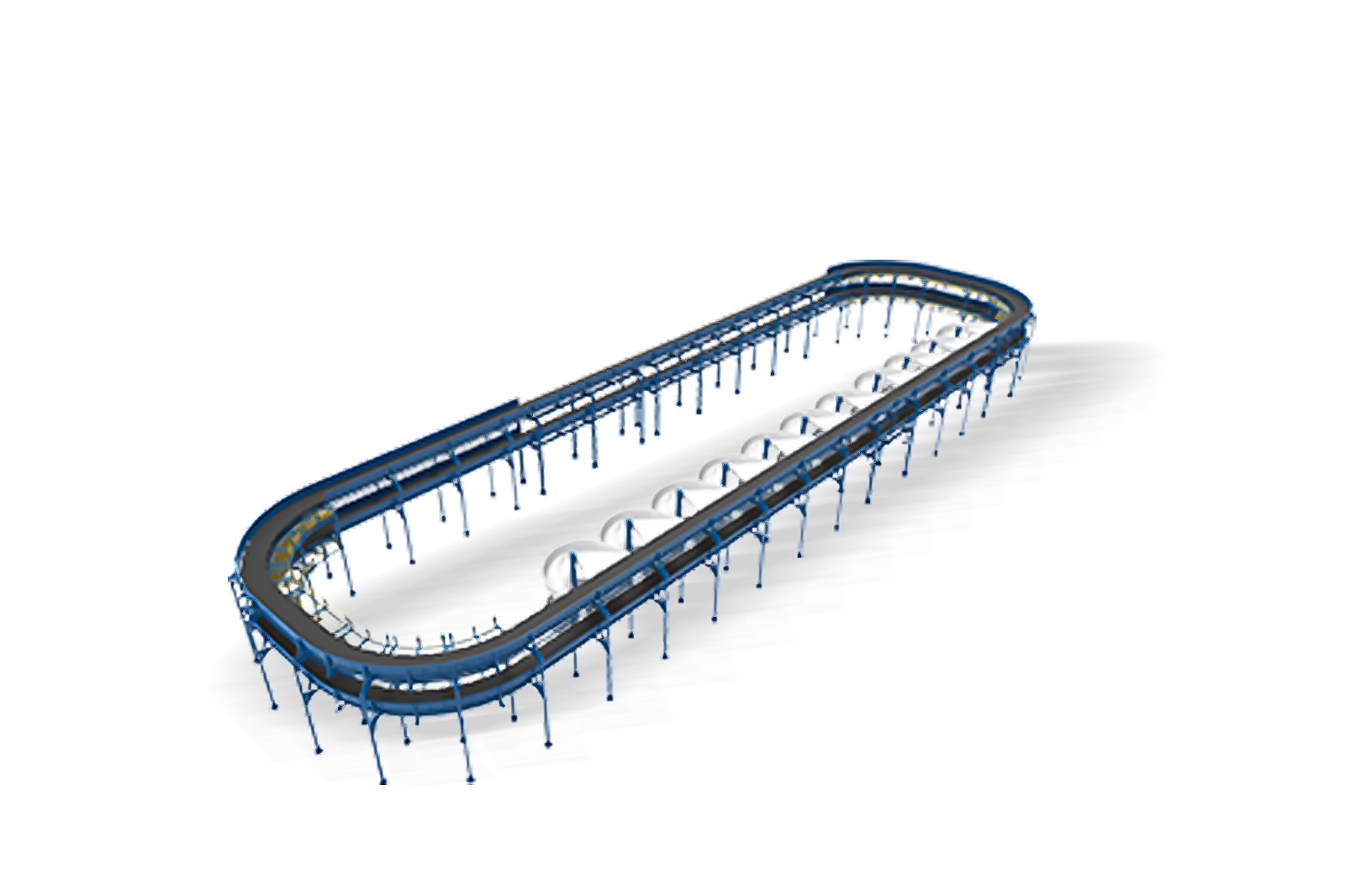

Loop Cross Belt Sorter

Linear Cross Belt Sorter

Individual Carrier System

Divert Roller Conveyor

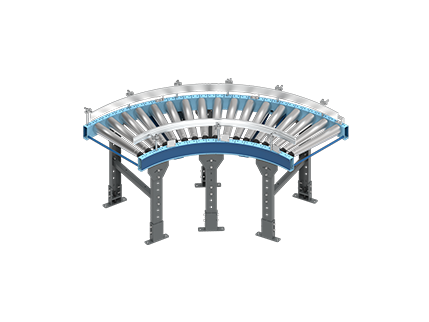

Curve Roller Conveyor

Edge Roller Conveyor

Fast Sorter

Motorised Roller for Alignment Conveyor

Drum Motor for Belt Conveyor – DM70

Drum Motor for Belt Conveyor – DM100

Drum Motor for Belt Conveyor – DM138

Drum Motor for Belt Conveyor – DM216

Barcode Reader Dedicated for Logistics

Handheld Barcode Reader

Mini Sorter S4

Mini Sorter S2

Mini Sorter S8

Mini Sorter SX-Z

Mini Sorter Scanner LS2

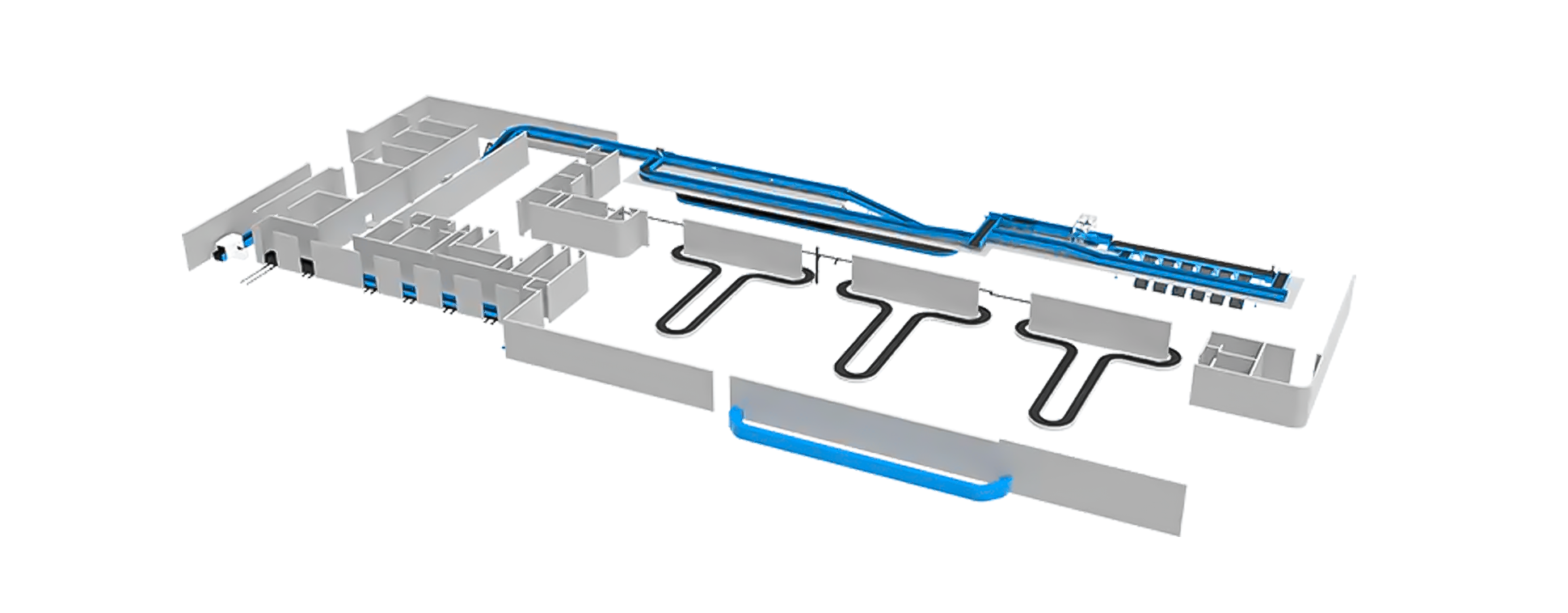

Warehouse Automation Solutions

As technology continues to advance, warehouses are increasingly adopting automation solutions to streamline their logistics operations. Automation solutions not only improve efficiency but also reduce labor costs and minimise errors. In this article, we will explore various warehouse automation solutions, including AGVs, AMRs, AS/RS, sortation systems, conveyor systems, and motorised roller systems.

- AGVs (Automated Guided Vehicles)

AGVs are robotic vehicles that are programmed to follow a specific path and transport materials, goods, and equipment within a warehouse. They are designed to operate in a repetitive and predictable environment, making them ideal for tasks such as pallet transportation, container unloading, and goods delivery. AGVs use various navigation technologies, such as laser guidance, magnetic guidance, or vision guidance, to move around the warehouse. They can operate 24/7 and significantly reduce labor costs associated with manual transportation.

- AMRs (Autonomous Mobile Robots)

AMRs are similar to AGVs but are equipped with advanced sensors and navigation systems that enable them to navigate through unpredictable environments. They can avoid obstacles, change routes, and adjust their speed and direction in real-time. AMRs are ideal for tasks such as picking and packing, inventory management, and order fulfillment. They can operate in a variety of warehouse settings, including those with narrow aisles and tight spaces.

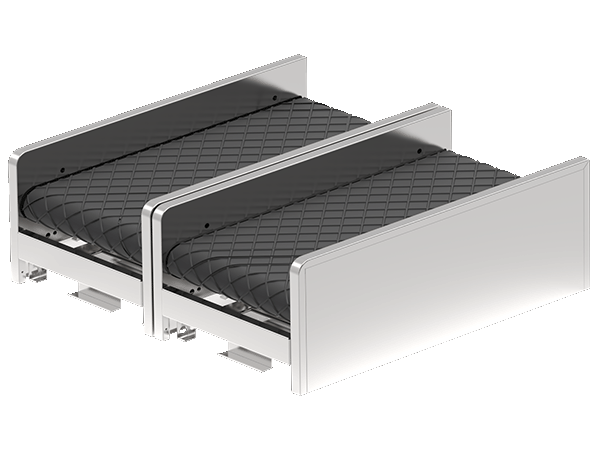

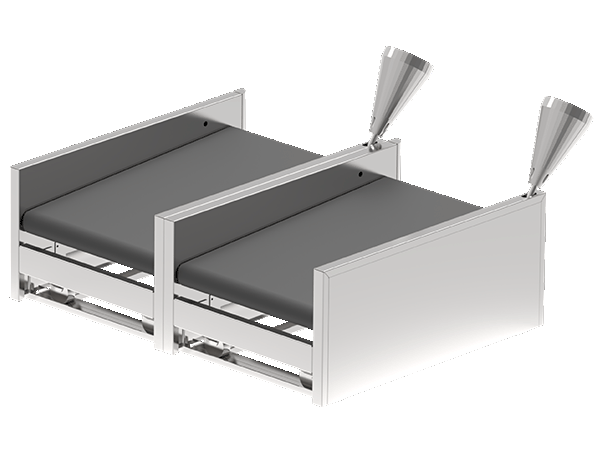

- AS/RS (Automated Storage and Retrieval Systems)

AS/RS are automated systems that store and retrieve items and products within a warehouse. They are designed to optimise storage space and improve inventory management. AS/RS systems use various technologies, such as robots, cranes, and elevators, to store and retrieve items from storage locations. They can operate in a variety of warehouse settings, including cold storage, dry storage, and freezer storage. AS/RS systems significantly improve inventory accuracy and reduce labor costs associated with manual storage and retrieval.

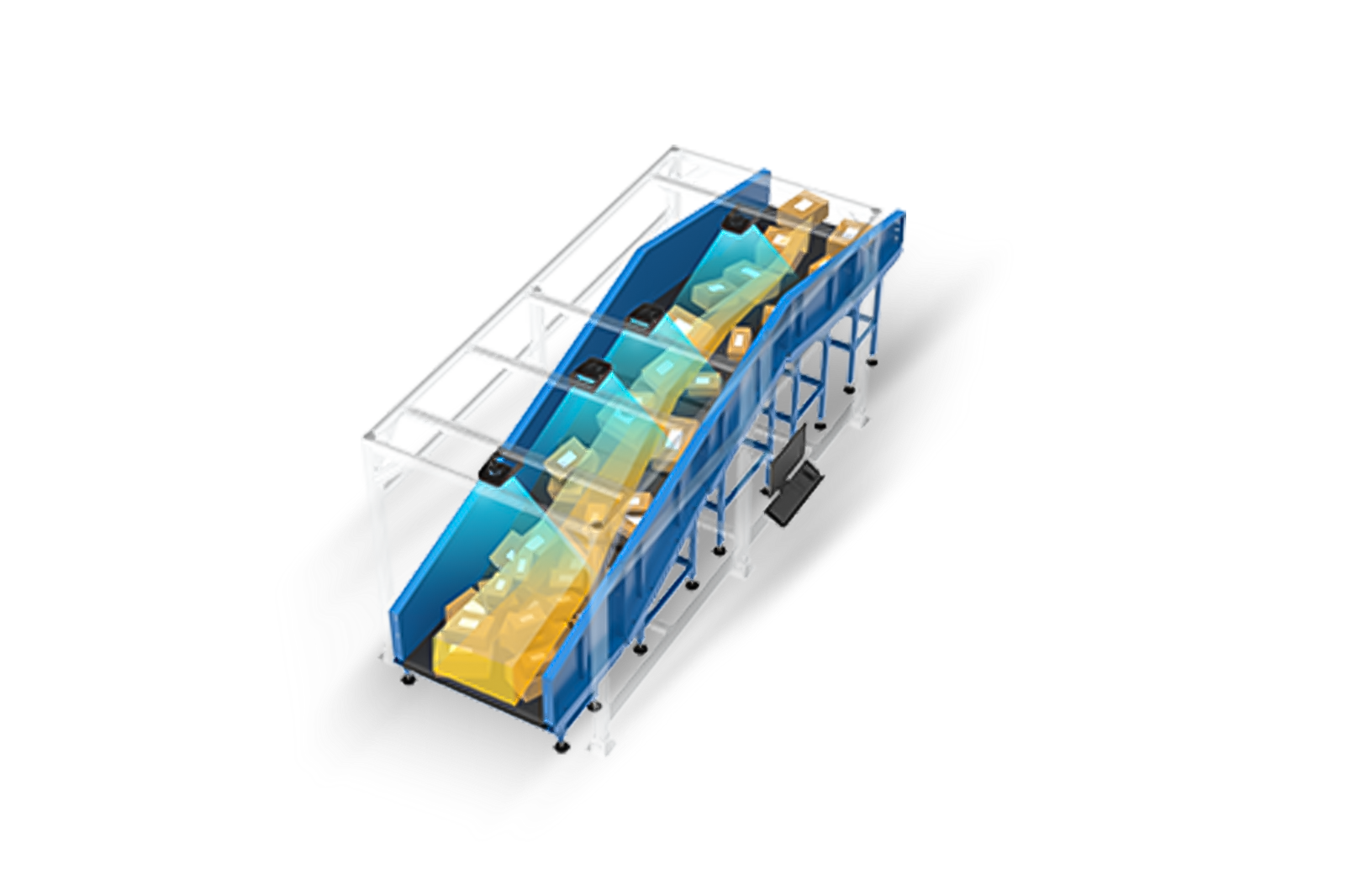

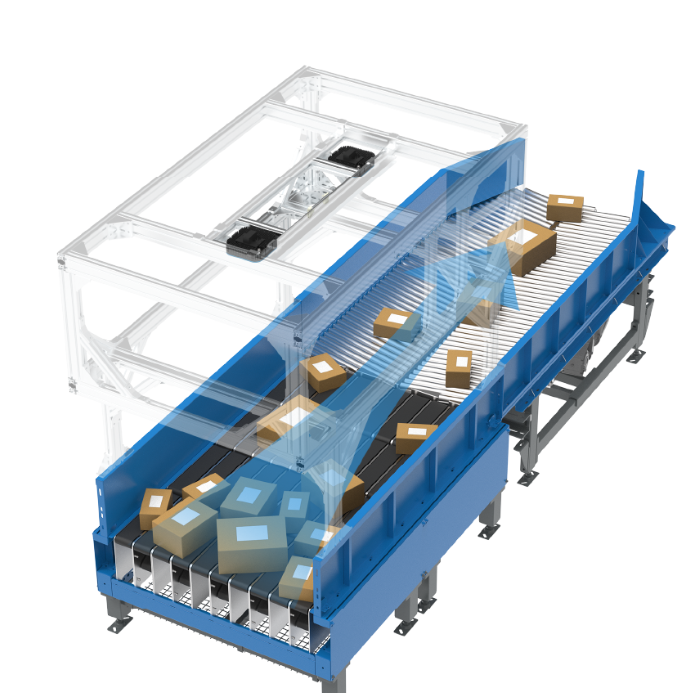

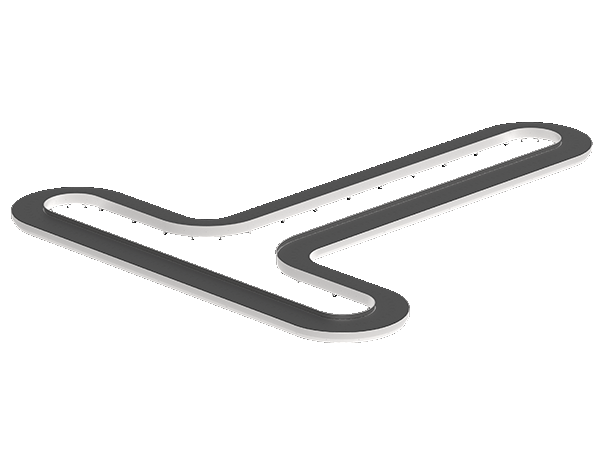

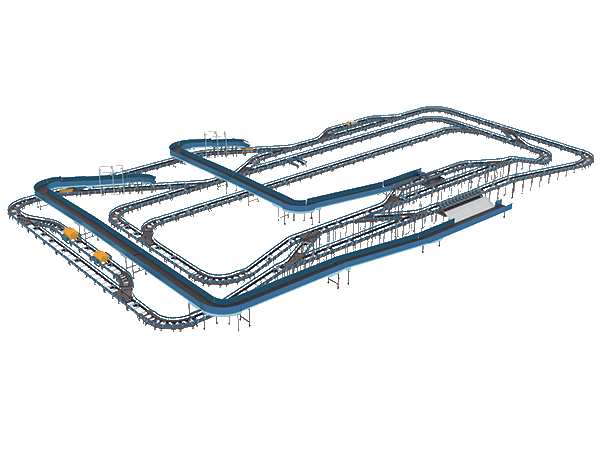

- Sortation Systems

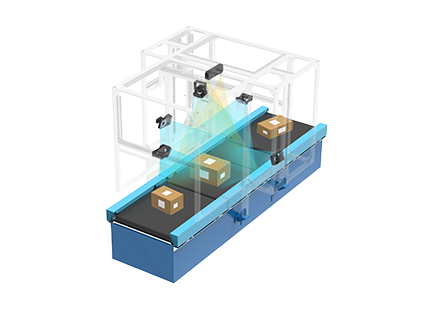

Sortation systems are automated systems that sort items and products based on their destination, product type, or other criteria. They are designed to optimise the sorting process and reduce manual labor. Sortation systems use various technologies, such as conveyor belts, diverters, and sorters, to sort items at high speeds. They can operate in a variety of warehouse settings, including e-commerce fulfillment, parcel delivery, and manufacturing. Sortation systems significantly improve sorting efficiency and accuracy.

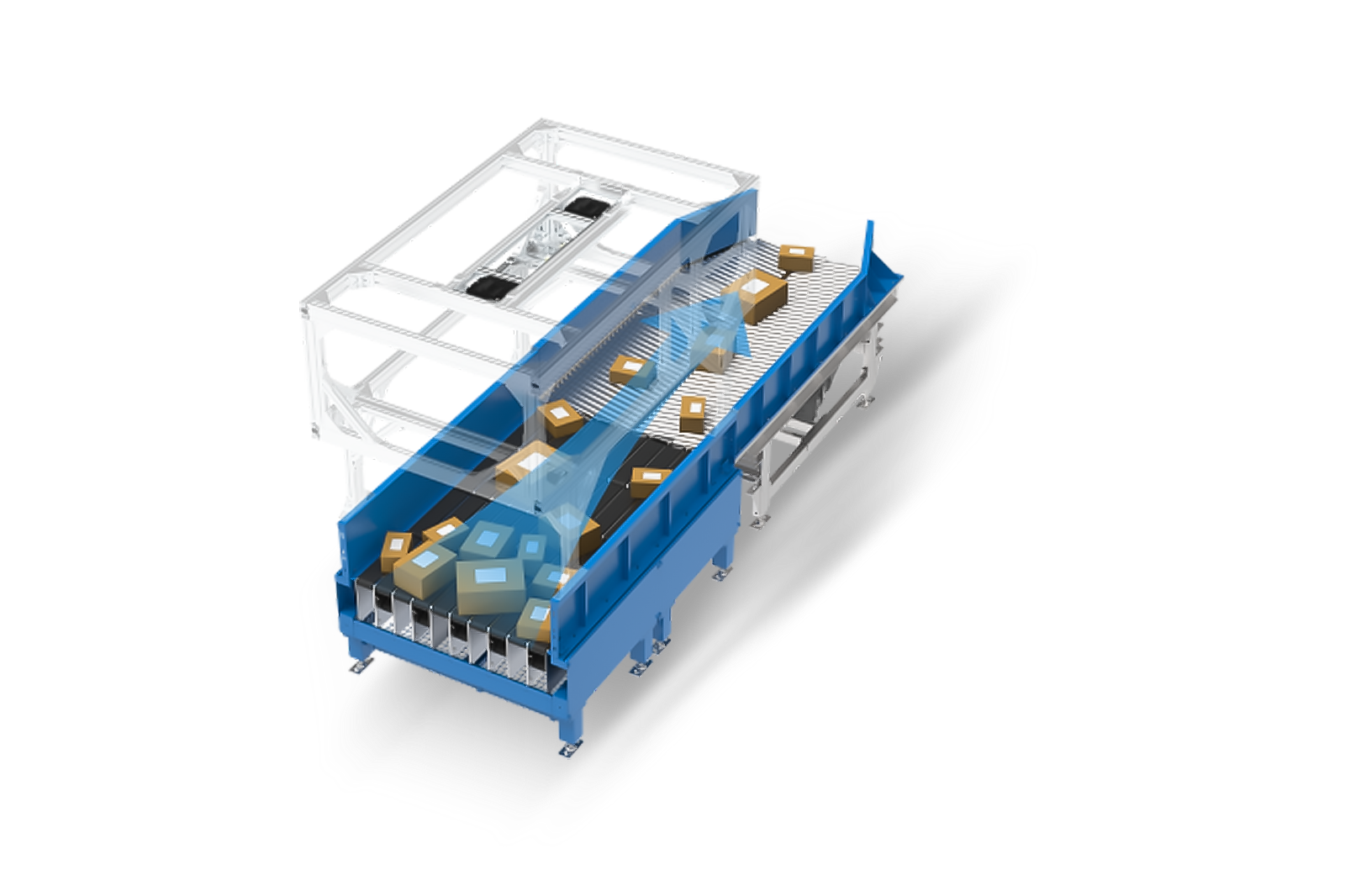

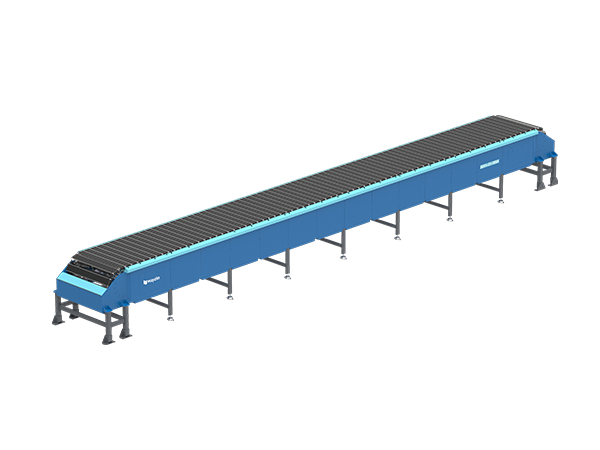

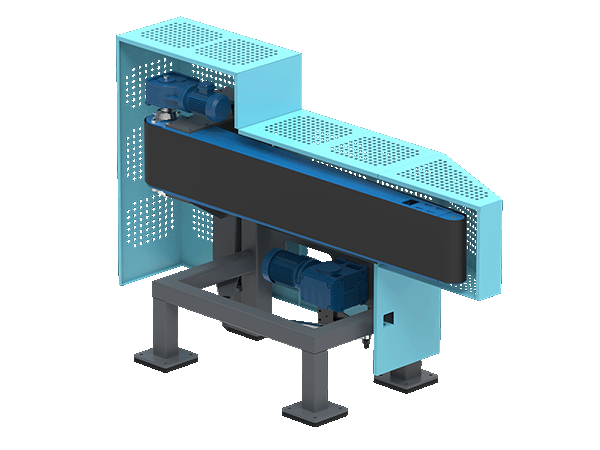

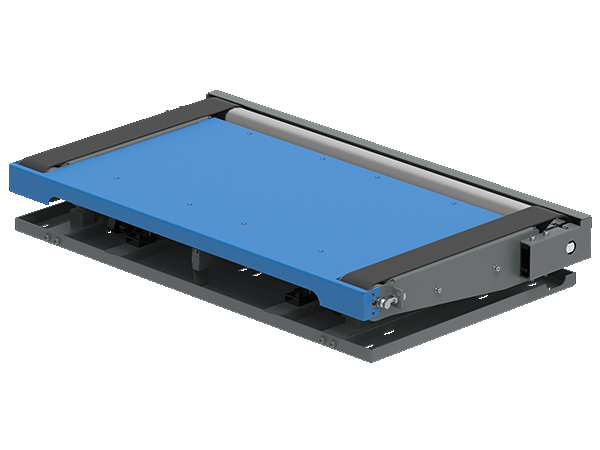

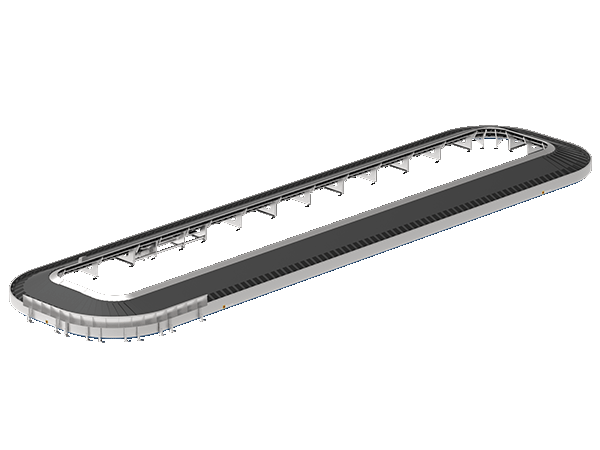

- Conveyor Systems

Conveyor systems are automated systems that transport items and products within a warehouse. They are designed to optimize the transportation process and reduce manual labor. Conveyor systems use various technologies such as belts, chains, and rollers to transport items at high speeds. They can operate in a variety of warehouse settings, including manufacturing, assembly, and order fulfillment. Conveyor systems significantly improve transportation efficiency and accuracy.

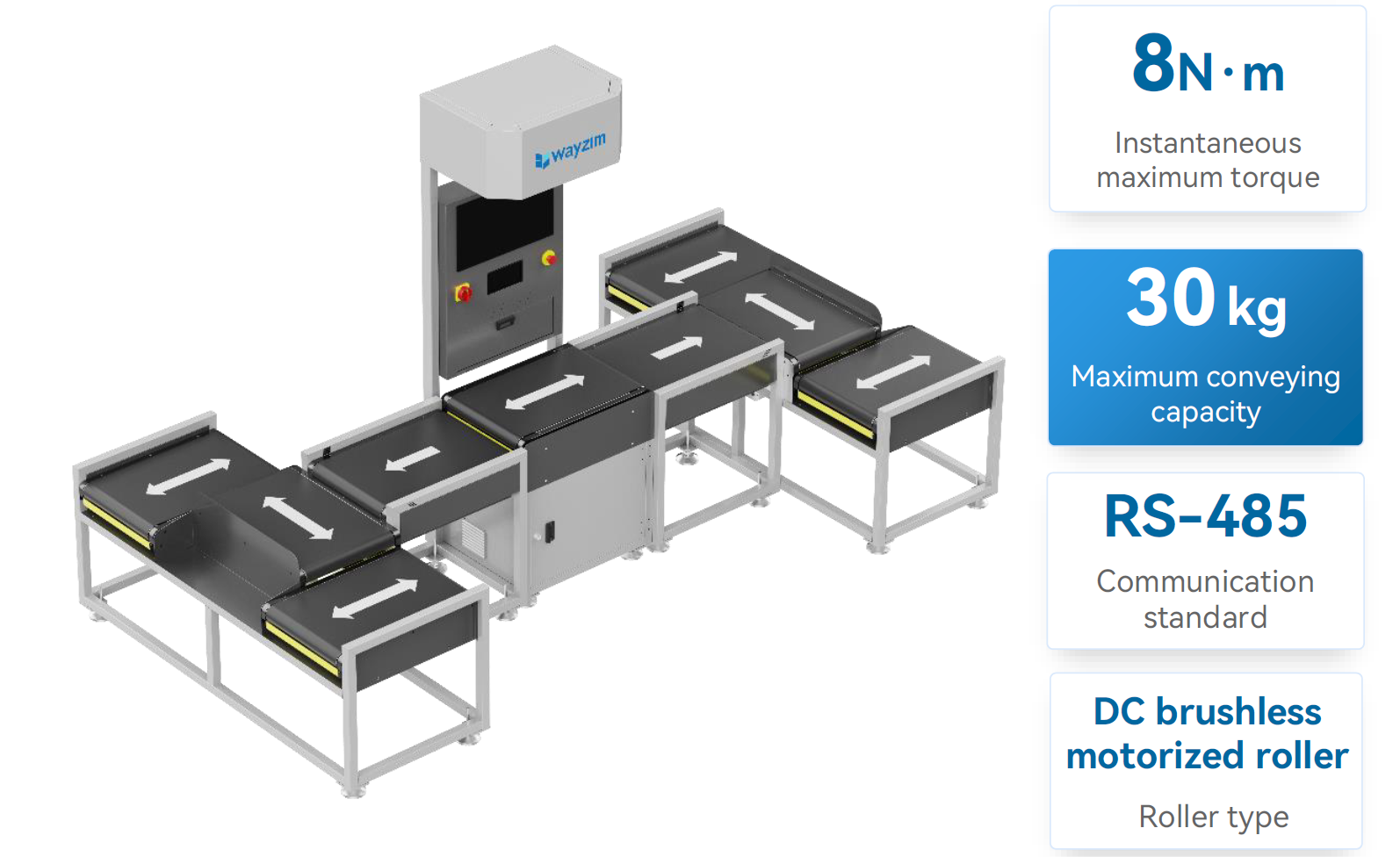

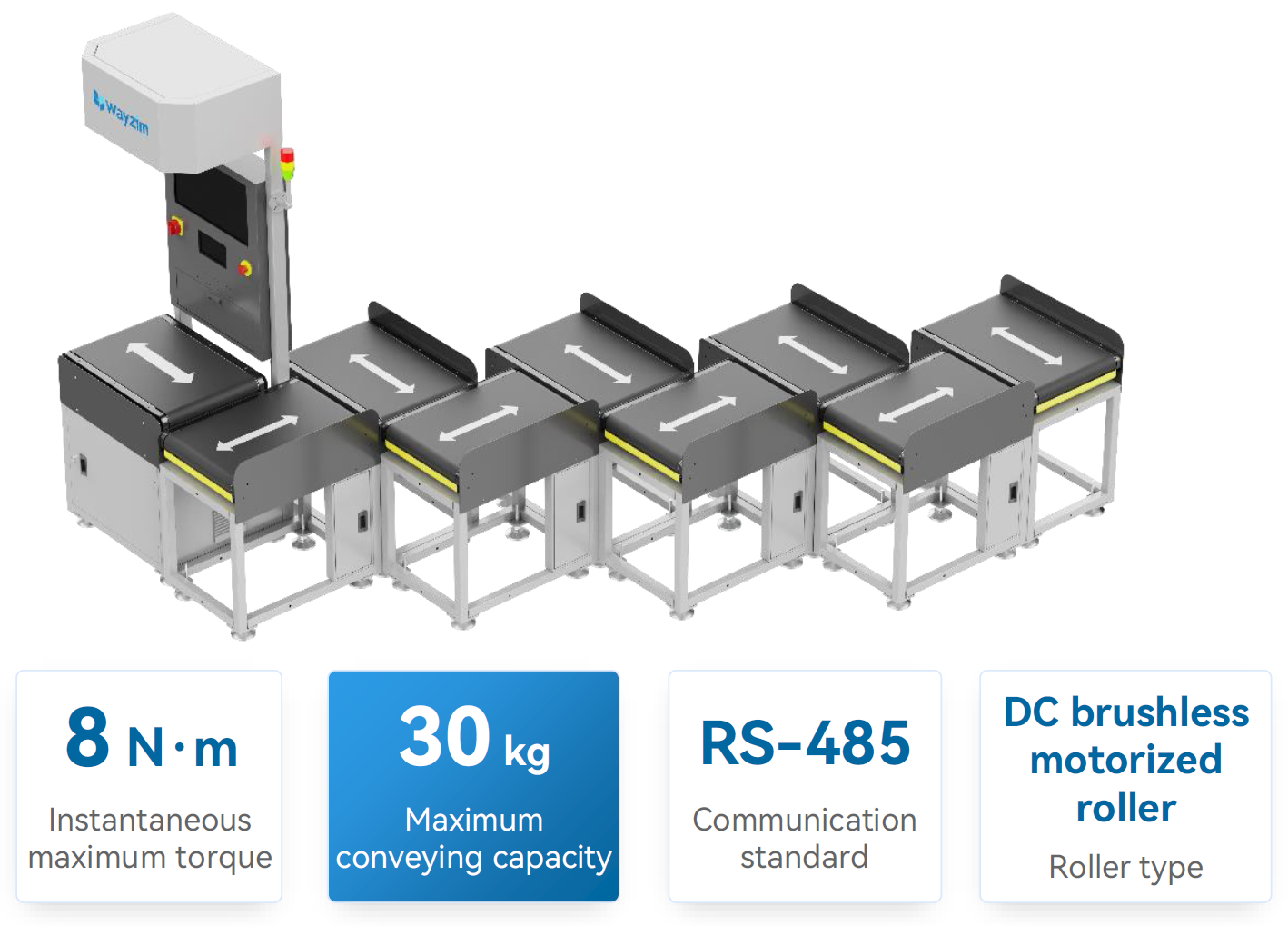

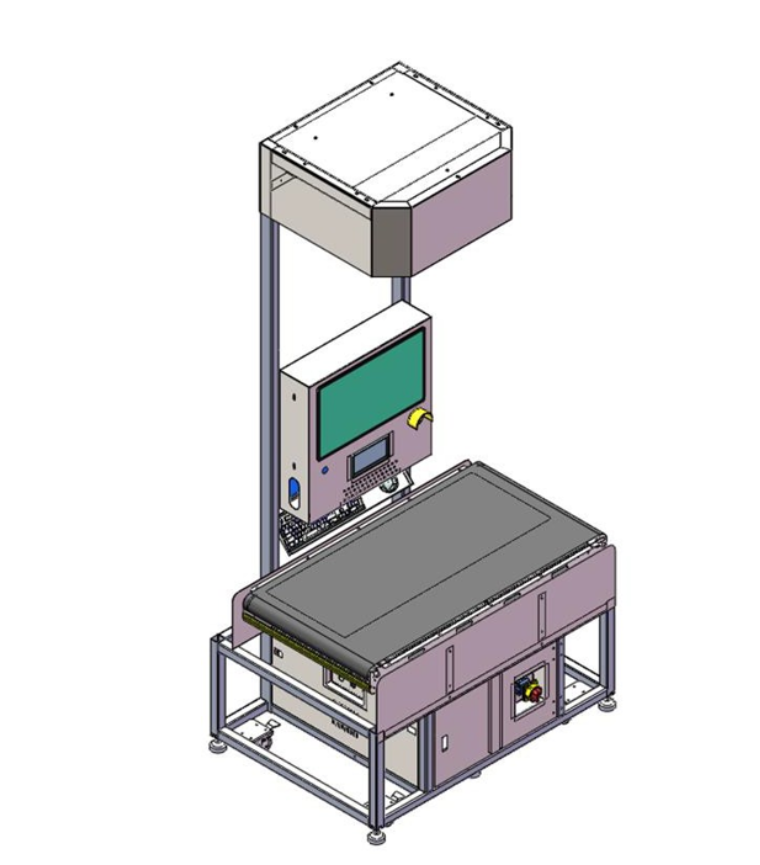

- Motorised Roller Systems

Motorised roller systems are automated systems that use rollers to transport items and products within a warehouse. They are designed to optimise the transportation process and reduce manual labor. Motorised roller systems use electric motors to drive the rollers, enabling them to transport items at high speeds. They can operate in a variety of warehouse settings, including manufacturing, assembly, and order fulfillment. Motorised roller systems significantly improve transportation efficiency and accuracy.

Warehouse automation solutions are revolutionising logistics operations. AGVs, AMRs, AS/RS, sortation systems, conveyor systems, and motorised roller systems are just a few of the many automation solutions available to warehouses. These solutions not only improve efficiency but also reduce labor costs and minimise errors. As technology continues to advance, we can expect to see even more innovative automation solutions emerge in the future.

Benefits of Automation

for forward-thinking companies

When robots and automation are implemented in a business effectively, they don’t replace jobs. They augment them to drive greater productivity.

- Greater speed

- Increased accuracy

- Increased Warehouse Safety

- Adaptable Workforce

- Innovative Brand Image

- Higher Customer Satisfaction