This state-of-the-art mobile robot is a game-changer, blending the efficiency of forklift technology with the intelligence of Autonomous Mobile Robots (AMR).

1. High-precision operation: Our Forklift AMR boasts the ability to pick and stack with an accuracy of ±100 mm and ±10°, ensuring seamless operations.

2. Efficient operation: Enhanced Lifting Capabilities: With a high lifting capacity of 1.6/3.0 m and a load capacity of 1400 kg, it’s designed to handle the most demanding logistics tasks.

3. Digital operation: The Forklift AMR offers flexible deployment, intelligent scheduling, and seamless digital integration, making it a versatile solution for various industrial and warehousing needs.

The application of our unmanned forklift is a significant step towards solving the challenges of high logistics volume and labor intensity in industrial production and warehousing logistics. It’s not just a robot; it’s a partner in efficiency and innovation.

Wayzim’s Forklift AMR is packed with cutting-edge features, designed to meet the dynamic demands of modern logistics. Here’s what makes it stand out:

𝟏.𝐋𝐚𝐬𝐞𝐫 𝐒𝐋𝐀𝐌 𝐍𝐚𝐯𝐢𝐠𝐚𝐭𝐢𝐨𝐧

Achieves precise positioning (accuracy within 10 mm) without relying on reflective columns, enabling flexibility and adaptability in various environments.

𝟐.𝐌𝐮𝐥𝐭𝐢-𝐋𝐞𝐯𝐞𝐥 𝐒𝐚𝐟𝐞𝐭𝐲 𝐏𝐫𝐨𝐭𝐞𝐜𝐭𝐢𝐨𝐧

Equipped with a robust safety system, including a TOF camera, safety laser, and safety contact sensors, ensuring reliable and safe operations.

𝟑.𝐀𝐜𝐜𝐮𝐫𝐚𝐭𝐞 𝐅𝐨𝐫𝐤𝐢𝐧𝐠 𝐚𝐧𝐝 𝐒𝐭𝐚𝐜𝐤𝐢𝐧𝐠

Allows high-precision forking and stacking within ±100mm and ±10°, supporting precise handling and placement of goods.

𝟒.𝐇𝐢𝐠𝐡 𝐋𝐢𝐟𝐭𝐢𝐧𝐠 & 𝐇𝐞𝐚𝐯𝐲 𝐋𝐨𝐚𝐝 𝐂𝐚𝐩𝐚𝐜𝐢𝐭𝐲

Handles lifting heights from 0.125m up to 10m and can manage loads from 1.4 to 3 tons, making it ideal for handling a range of materials in different warehouse settings.

𝟓.𝐂𝐨𝐦𝐩𝐚𝐜𝐭 𝐁𝐨𝐝𝐲 𝐟𝐨𝐫 𝐍𝐚𝐫𝐫𝐨𝐰 𝐀𝐢𝐬𝐥𝐞𝐬

Designed for tight spaces, its right-angle stacking width is much smaller than that of traditional forklifts, maximising operational efficiency in narrow aisles.

𝟔.𝐌𝐮𝐥𝐭𝐢-𝐋𝐨𝐠𝐢𝐜 𝐈𝐧𝐭𝐞𝐥𝐥𝐢𝐠𝐞𝐧𝐭 𝐂𝐡𝐚𝐫𝐠𝐢𝐧𝐠

Features intelligent charging logic that enables automatic charging during idle times and forced charging when power is low, ensuring consistent operational readiness.

𝐇𝐚𝐫𝐝𝐰𝐚𝐫𝐞 𝐚𝐛𝐬𝐭𝐫𝐚𝐜𝐭 𝐬𝐲𝐬𝐭𝐞𝐦 𝐨𝐟 𝐅𝐨𝐫𝐤𝐥𝐢𝐟𝐭 𝐀𝐌𝐑

It is composed of a driver kernel and a hardware adapter program and is developed using a complete vehicle body driver development template. It can quickly develop control drivers for different AMRs, quickly adapt different types of sensors to different scene needs, use a computer or a handle to remotely control the movement, and test and verify all the hardware functions of the AMRs. The following are the key technologies of the system:

𝟏.𝐋𝐢𝐠𝐡𝐭𝐰𝐞𝐢𝐠𝐡𝐭 𝐚𝐧𝐝 𝐂𝐨𝐧𝐯𝐞𝐧𝐢𝐞𝐧𝐭 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭

The modular design of the kernel can quickly adapt to different brands and types of sensors.

𝟐.𝐈𝐧𝐭𝐞𝐠𝐫𝐢𝐭𝐲 𝐨𝐟 𝐑𝐞𝐦𝐨𝐭𝐞 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 𝐕𝐞𝐫𝐢𝐟𝐢𝐜𝐚𝐭𝐢𝐨𝐧 𝐅𝐮𝐧𝐜𝐭𝐢𝐨𝐧

After the on-board IPC is adapted, the AMR can be controlled to run through the handle, which is convenient and reliable.

𝟑.𝐀𝐌𝐑 𝐎𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐒𝐭𝐚𝐭𝐮𝐬 𝐃𝐢𝐚𝐠𝐧𝐨𝐬𝐭𝐢𝐜𝐬 𝐚𝐧𝐝 𝐋𝐨𝐠

The running status of AMR components can be monitored through a visual interface to facilitate the development and running fault diagnosis.

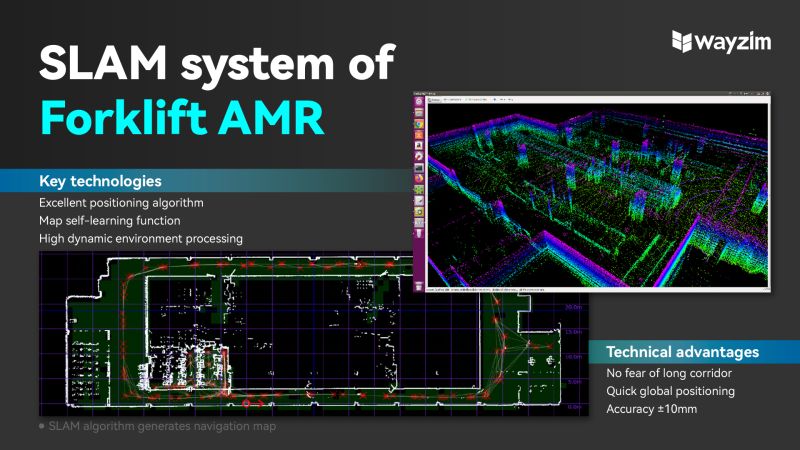

𝐒𝐋𝐀𝐌 𝐒𝐲𝐬𝐭𝐞𝐦 for Forklift AMR

Our advanced SLAM (Simultaneous Localisation and Mapping) system enables our Forklift AMRs to navigate dynamic and complex environments with precision and adaptability. By leveraging cutting-edge sensor information, our AMRs can map and position themselves in real-time, ensuring seamless operation in unknown spaces.

𝐊𝐞𝐲 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬

1.Excellent Positioning Algorithm: Using point cloud data, our algorithm delivers high accuracy, supporting ±10mm precision even in challenging scenarios.

2.Map Self-Learning Function: The map updates dynamically, ensuring that AMRs adapt to changes instantly, enhancing timeliness and efficiency.

3.High Dynamic Environment Processing: Equipped with dynamic object recognition, our system maintains precise positioning even in fast-changing environments where people and vehicles are constantly on the move.

𝐓𝐞𝐜𝐡𝐧𝐢𝐜𝐚𝐥 𝐀𝐝𝐯𝐚𝐧𝐭𝐚𝐠𝐞𝐬

A. Navigates long corridors effortlessly

B. Enables quick global positioning

C. Provides accuracy up to ±10mm

𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐜 𝐍𝐚𝐯𝐢𝐠𝐚𝐭𝐢𝐨𝐧 𝐒𝐲𝐬𝐭𝐞𝐦 for Forklift AMR

The Automatic Navigation System is a cutting-edge tool that empowers our Forklift AMRs to navigate with high precision and adaptability. Beyond simple navigation, it integrates advanced algorithms and practical functions for seamless operation in dynamic environments.

𝐊𝐞𝐲 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬:

1.Multiple Vehicle Body Control Algorithms: Our system uses fuzzy logic and robust control algorithms, allowing for easy parameter adjustments and smooth control.

2.Plug-In Development of Vehicle Model Module: With a standardised motion model, the system can adapt quickly to various vehicle types without extra programming, enhancing flexibility.

3.Integrated Practical Functions: Equipped with features like automatic charging, multi-directional obstacle avoidance, pallet and shelf detection, high-precision stacking, and edge/line following, the navigation system covers every aspect of efficient warehouse operation.

This comprehensive solution ensures that our Forklift AMRs meet the evolving demands of modern logistics with accuracy and efficiency.

Revolutionising AMR Traffic Management with Wayzim’s 𝐃𝐢𝐬𝐩𝐚𝐭𝐜𝐡𝐢𝐧𝐠 𝐒𝐲𝐬𝐭𝐞𝐦

This cutting-edge system integrates intelligent global path optimisation algorithms and traffic control algorithms, ensuring seamless allocation of map resources and precise traffic strategy management.

𝐊𝐞𝐲 𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬:

1.Static Path Traffic Command Function: It can completely avoid vehicle conflict in running, and once the task is issued, AMR accessibility can be guaranteed

2.Ultra-High Dispatching Capacity: It has low communication requirements and high performance of traffic command kernel, and can handle more than 2000 traffic requests per second and efficiently command the AMR cluster.

3.Carrier Actions Based on Path Programming: This is generated with scripted actions, which can widely support various vehicle models and business scenarios.

Tailored for diverse industries, including logistics, warehousing, e-commerce, fresh food, and even automotive manufacturing, our Forklift AMR redefines efficiency in material handling.

Real-world Applications:

1. Efficient 𝐝𝐞𝐧𝐬𝐞 𝐬𝐭𝐚𝐜𝐤𝐢𝐧𝐠 and 𝐬𝐡𝐞𝐥𝐟 𝐚𝐜𝐜𝐞𝐬𝐬.

2. Smooth 𝐦𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐫𝐚𝐜𝐤 𝐝𝐨𝐜𝐤𝐢𝐧𝐠 and 𝐭𝐫𝐚𝐧𝐬𝐩𝐨𝐫𝐭 𝐝𝐨𝐜𝐤𝐢𝐧𝐠.

3. Specialised tasks like 𝐜𝐨𝐢𝐥𝐞𝐝 𝐦𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐡𝐚𝐧𝐝𝐥𝐢𝐧𝐠 and 𝐟𝐢𝐧𝐢𝐬𝐡𝐞𝐝 𝐩𝐫𝐨𝐝𝐮𝐜𝐭𝐬 𝐨𝐟𝐟 𝐭𝐡𝐞 𝐚𝐬𝐬𝐞𝐦𝐛𝐥𝐲 𝐥𝐢𝐧𝐞.

4. Integrated workflows with 𝐬𝐭𝐞𝐫𝐞𝐨𝐬𝐜𝐨𝐩𝐢𝐜 𝐰𝐚𝐫𝐞𝐡𝐨𝐮𝐬𝐞 𝐝𝐨𝐜𝐤𝐢𝐧𝐠 and 𝐞𝐥𝐞𝐯𝐚𝐭𝐨𝐫 𝐝𝐨𝐜𝐤𝐢𝐧𝐠.

By automating these crucial workflows, the Forklift AMR boosts productivity, reduces manual errors, and adapts to dynamic operational needs.