Matrix Pivot Wheel Sorting System Provides a High Throughput Sorting Solution for the Logistics Industry

The pivot wheel sorting system, as an independent module seamlessly integrated into a logistics system, can be flexibly deployed on conveyor lines to meet different customer needs for sorting systems.

In some large-capacity sorting centres, faced with complex inbound lines, Pivot Wheel Sorters can be used in conjunction with outbound conveyors. Multiple pivot wheel sorting lines are connected by sharing the same outbound conveyor, forming a matrix sorting system.

01. Conveyor

Used in conjunction with Pivot Wheel Sorters, conveyors play a critical role in the entire system as the backbone of parcel conveyance, responsible for the multi-location conveyance of parcels.

02. Pivot Wheel Sorters in the Matrix Area

The 6K Pivot Wheel Sorter, as a common model in the matrix Pivot Wheel Sorter area, is efficient equipment used in sorting systems. Combining servo motors and motorised rollers, it can accurately and efficiently sort various types of items. It is particularly suitable for items that are difficult to sort, such as soft bags and consolidation bags.

In addition to its advantages for sorting all types of items, the Pivot Wheel Sorter uses a modular design, making it easy to assemble and replace. Therefore, the Pivot Wheel Sorter is suitable for the needs of various types of sites.

03. Multiple Pivot Wheel Sorting Lines

The multiple pivot wheel sorting lines in the system are connected to conveyors, forming a matrix structure. The advantage of this structure is that parcels can enter the system from any inbound point (that is, any inbound conveyor line) and then be sorted to the corresponding outbound line through Pivot Wheel Sorters.

The model currently used in the matrix Pivot Wheel Sorter area is the Wayzim 6K Pivot Wheel Sorter. The product uses multi-power unit motion control technology and small-sized motorised rollers, which significantly enhances the equipment’s fault tolerance and stability. Besides, the modular structure design allows for quick assembly and replacement of all components.

Motorised rollers and friction wheels are covered with rubber or polyurethane, effectively preventing damage to item surfaces during sorting, enabling fast, precise, and flexible sorting, and especially suitable for fragile items. Moreover, the Pivot Wheel Sorter has three times the overload resistance capability and features overload protection and automatic reset functions, further enhancing the system’s reliability and durability.

- Efficient sorting

The sorting efficiency can reach 6000 pcs/h, and the sorting speed can be adjusted between 0.8 to 2.3 m/s.

- Modular design

All components can be quickly assembled and replaced, especially the motorised roller unit that can be replaced in one minute.

- High system fault tolerance

Adopting multi-power unit motion control and multi-motor drive control technologies, each multi-motor drive can independently control two motorised rollers, and the power units use a proper servo arrangement so that the failure of a single power unit does not affect the overall equipment operation, effectively improving the fault tolerance and stability of parcel sorting without impacting functionality.

- Safe and stable sorting

The equipment employs motorised rollers and friction wheels covered with rubber or polyurethane, significantly reducing the item damage risk. Therefore, it is particularly suitable for sorting fragile items.

- Overload resistance capability

The equipment has three times the overload resistance capability. After an overload alarm, the dual-motor drive protects motorised rollers from overload, preserving the lifespan of the motorised rollers, and restarts after 20 seconds.

Operation Process

During the operation of the Pivot Wheel Sorter, the system makes real-time adjustments based on instructions issued by the upper-level computer. The photoelectric sensor equipped at the front end of the Pivot Wheel Sorter continuously monitors the status of the items passing by. These signals from photoelectric sensors enable the servo motor to precisely adjust the operating posture of each coated unit, achieving efficient parcel sorting.

Ultimately, sorted parcels are smoothly delivered to their corresponding diverting conveyors, ensuring the smooth operation of the entire system.

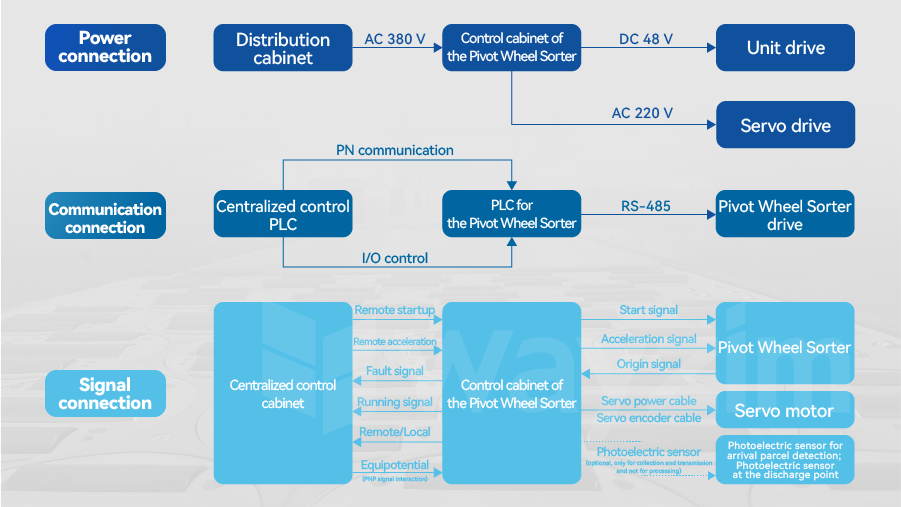

PLC Control System

In the matrix pivot wheel sorting lines, PLC control systems are widely used. In the remote mode, the PLC for the Pivot Wheel Sorter uses PN communication and I/O control to receive remote commands for operations such as starting, stopping, turning, and speed adjustments, and interact with the main control device for exchanging information such as operating status, faults, and emergency stop signals.

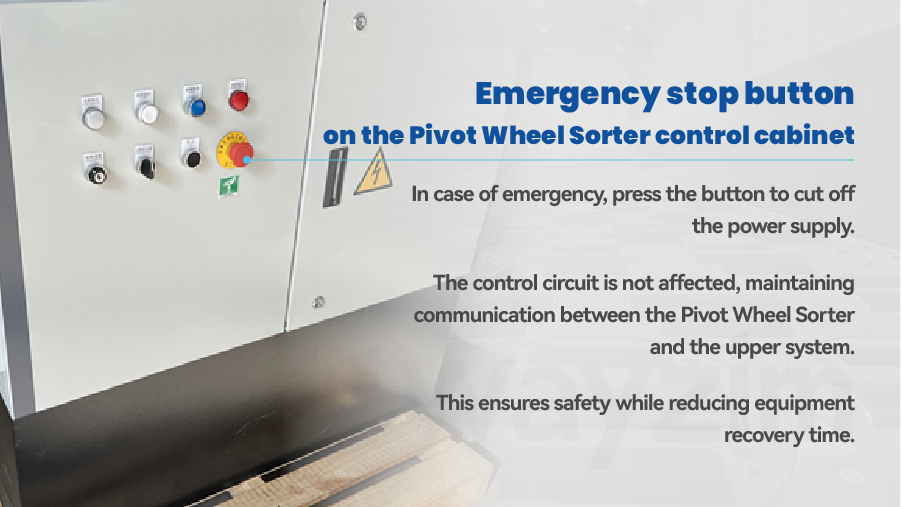

The Pivot Wheel Sorter control cabinet is equipped with an emergency stop button. When the button is pressed in an emergency, the power circuit is disconnected, but the control circuit remains unaffected, and the emergency stop signal is fed back to the control unit. The remote mode achieves efficient information interaction, allowing the Pivot Wheel Sorter to flexibly receive instructions and adjust its operating status, thereby enhancing operation convenience.

The matrix pivot wheel sorting system combines multiple pivot wheel sorting lines with conveyors, ensuring the smooth entry of upstream parcels into the sorting process. Sorted parcels are conveyed to downstream collection or distribution systems through outbound conveyors. Whether for subsequent conveyance, packaging, or direct shipping, the system can adapt flexibly. The matrix pivot wheel sorting system is seamlessly integrated into modern logistics networks through its modular design, precise sorting capabilities, and efficient operational processes.

The system can handle large-scale parcels while ensuring that parcels arrive accurately and quickly at their designated destinations, widely used in large-scale e-commerce logistics sorting. While significantly improving logistics efficiency, it meets the growing demand for large-capacity sorting.