Warehouse automation is reshaping supply chain management, providing unprecedented efficiency and cost savings. As businesses strive to keep up with consumer demands and technological advancements, automated solutions are becoming essential components of modern warehouses. This article delves into the evolution of warehouse automation, its benefits, recent developments, challenges, and future trends, particularly highlighting its relevance for media publishers managing physical products.

Overview of Warehouse Automation

Warehouse automation refers to using technology to streamline warehouse processes, from inventory management to order fulfilment. Over the years, these technologies have evolved significantly—from early conveyor systems to today’s advanced robots and AI-driven solutions.

For 3PL service providers, warehouse automation is particularly relevant, as it enables efficient distribution of physical products, such as consumer goods and retail items, thereby reducing operational costs, improving delivery times, and enhancing scalability. Automation technologies, such as AGVs and AMRs, can handle repetitive and labor-intensive tasks, allowing 3PL providers to focus on value-added services like customer support and strategic planning. Given the challenges posed by increasing consumer expectations, rising operational expenses, and seasonal fluctuations in demand, automation can be a game-changer for the logistics industry, driving increased competitiveness and long-term growth.

Types of Warehouse Automation Technologies

1. Automated Guided Vehicles (AGVs)

AGVs are mobile robots designed to transport materials within warehouses. These vehicles follow predetermined paths using sensors or magnetic strips, making them ideal for moving items between different sections of a warehouse. AGVs provide reliability and consistency, excelling in repetitive tasks where precision is critical. By reducing the need for manual material handling, AGVs improve overall efficiency.

2. Autonomous Mobile Robots (AMRs)

Unlike AGVs, AMRs can navigate warehouses dynamically, using advanced sensors and AI to adapt to real-time changes in their environment. This makes them highly versatile for picking and transporting goods. AMRs can efficiently navigate around obstacles and collaborate with other warehouse technologies, making them suitable for environments requiring flexibility and adaptability.

3. Automated Storage and Retrieval Systems (AS/RS)

AS/RS are sophisticated systems that automate the storage and retrieval of goods. Comprised of cranes, shuttles, and conveyors, AS/RS optimise space utilisation by efficiently storing items in high-density racks. This technology not only reduces manual labour but also minimises the risk of errors in inventory management. AS/RS are instrumental in achieving high accuracy and optimising warehouse space.

4. Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers in warehouses, assisting in tasks such as picking, packing, and sorting. Cobots enhance productivity by automating repetitive, labour-intensive tasks while allowing human employees to focus on complex activities. Their ability to interact safely with humans makes them ideal for boosting operational efficiency while ensuring worker safety.

5. Robotic Arms

Robotic arms bring precision to warehouse operations by performing tasks that require accuracy, such as handling delicate items or repetitive actions like packing. They are particularly valuable in environments where precision is crucial, such as in packaging fragile goods. With their high accuracy and ability to operate continuously, robotic arms are key contributors to efficiency and cost reduction.

6. Automated Sortation Systems

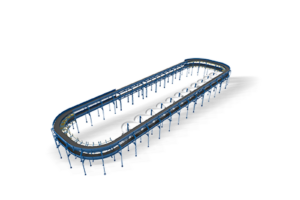

Automated sortation systems are used to identify items on a conveyor system and divert them to specific destinations based on predefined criteria. These systems utilise advanced scanning technologies, such as barcode readers, RFID, and computer vision, as well as sophisticated algorithms to determine the correct path for each item, ensuring efficient and accurate distribution. Commonly employed in warehouses to streamline the sorting process for order fulfilment, automated sortation systems play a crucial role in directing items to their respective shipping or storage locations.

These systems are capable of handling large volumes of items, sorting them with remarkable speed and precision. By automating the sortation process, warehouses can significantly reduce manual labour, improve accuracy, minimise errors, and increase throughput, particularly during peak operational periods when demand is at its highest. Additionally, automated sortation systems provide real-time tracking and data analytics, allowing for improved inventory management and operational insights.

Which Warehouse Processes Can Be Automated

Warehouse automation can be applied to a wide range of processes, enabling greater efficiency, accuracy, and cost savings. Key warehouse processes that can be automated include:

1. Inventory Management: Automated systems, such as RFID and barcode scanning, can track inventory levels in real time, ensuring accurate stock counts and reducing the likelihood of overstocking or stockouts.

2. Picking and Packing: Automated picking systems, including robotic arms and AMRs, can efficiently locate and pick items from storage. Cobots can assist human workers in packing items, ensuring consistent quality and speed.

3. Staging: Automation can assist in staging items for shipping by organising and preparing goods for the final stages of the distribution process. Automated guided vehicles (AGVs) and robotic systems can streamline this step, ensuring that items are staged accurately and efficiently.

4. Loading: Automated loading systems can handle the movement of goods onto trucks or other transportation vehicles. Robotic loading arms and AGVs can streamline the loading process, reducing manual effort, minimising loading times, and ensuring goods are loaded safely and efficiently.

5. Receiving and Put-away: Automated conveyor systems and AGVs can handle the movement of goods from receiving docks to their designated storage locations, streamlining the put-away process and reducing manual labour.

6. Sorting: Automated sortation systems can categorise items based on predefined criteria, directing them to specific storage or shipping locations, which reduces sorting errors and increases throughput.

7. Order Fulfilment: Automation can be used to streamline the order fulfilment process, from picking items to packing and preparing them for shipping. AS/RS and AMRs are particularly useful in speeding up this process.

8. Quality Control: Vision systems and robotic technologies can be employed for automated quality control, inspecting items for defects before they are shipped, ensuring consistent product quality.

9. Shipping: Automated labelling and conveyor systems can handle the final stages of the order fulfilment process, preparing items for shipping, applying labels, and routing them to the correct loading areas.

Benefits of Implementing Warehouse Automation

1. Increased Efficiency

Automated systems accelerate warehouse processes like picking, packing, and shipping. Automated solutions operate without fatigue, leading to increased throughput and shorter lead times, which is crucial for meeting customer expectations in today’s fast-paced market.

2. Improved Accuracy

Automation significantly reduces the occurrence of human errors in tasks like inventory management and order fulfilment. By maintaining consistent accuracy, automated systems enhance order processing and boost customer satisfaction, reducing the likelihood of returns and complaints.

3. Cost Savings

While automation involves a high initial investment, the long-term benefits include reduced labour costs and increased productivity. Automating repetitive tasks reduces dependency on a large workforce, allowing companies to optimise labour allocation for more value-driven activities.

4. Enhanced Safety

By automating hazardous tasks, warehouse automation reduces the risk of workplace injuries. Human workers are no longer required to perform dangerous activities, creating a safer working environment and allowing them to focus on roles that require problem-solving and creativity.

5. Scalability

Automation provides the flexibility to scale operations based on demand. Whether dealing with seasonal spikes or unexpected increases in consumer orders, automated systems can be adjusted to meet varying demand levels, making them ideal for adapting to changing market conditions.

Recent Developments in Warehouse Automation

1. Amazon’s Robotics Integration

Amazon continues to lead in warehouse automation, integrating AI and robotics to reduce delivery times and operational costs. Their next-generation fulfilment centres leverage increased robotic deployment, showcasing the potential for faster and more efficient logistics.

2. Coles’ Investment in Robotic Distribution Centers

Australian supermarket giant Coles has made significant investments in robotic distribution centres, enhancing supply chain speed and capacity. This move not only improves operational efficiency but also strengthens their market competitiveness by offering faster deliveries and minimising supply chain disruptions.

3. Walmart’s Automation Strategy

Walmart has adopted automation to boost efficiency and reduce physical strain on employees. By implementing robotic technologies, Walmart aims to extend the careers of warehouse employees, allowing them to focus on supervisory and analytical roles instead of manual labour.

Challenges and Considerations

1. High Initial Investment

The implementation of warehouse automation requires significant upfront costs. Businesses must conduct thorough cost-benefit analyses to ensure a favourable return on investment. Although the long-term gains are substantial, the initial financial commitment can be a barrier for smaller companies.

2. Integration with Existing Systems

One of the key challenges is integrating new automation technologies with existing warehouse management systems (WMS). Compatibility issues can necessitate additional investments in software upgrades and employee training, increasing the complexity of the implementation process.

3. Workforce Adaptation

Automation often raises concerns about job displacement. To address these concerns, companies must focus on change management, providing training to help employees adapt to new roles and fostering a collaborative environment where humans and robots work together seamlessly.

Future Trends in Warehouse Automation

1. Artificial Intelligence and Machine Learning

AI and machine learning are set to play a vital role in warehouse automation, enabling more accurate predictions and improved decision-making. By analysing large datasets, AI can help optimise inventory management and adapt systems to changing conditions, enhancing overall efficiency.

2. Flexible Automation Solutions

The future of warehouse automation lies in flexible and modular systems that can be easily reconfigured to meet changing needs. These solutions will allow businesses to adapt quickly without significant disruptions or costs, making them ideal for dynamic environments.

3. Collaborative Robots (Cobots)

Cobots are expected to see increased adoption due to their ability to work alongside human workers, improving productivity while maintaining safety standards. Their versatility makes them suitable for a wide range of warehouse applications, especially where human-robot interaction is required.

4. Sustainability Initiatives

Sustainability is becoming a crucial focus in warehouse operations. Automation technologies can contribute to sustainable practices by optimising energy use and minimising waste, helping companies achieve their environmental goals while improving efficiency.

Warehouse automation is transforming supply chains, offering increased efficiency, accuracy, and cost savings. Recent advancements, such as Amazon’s and Coles’ robotic integrations, demonstrate the potential for significant improvements in logistics and distribution. For media publishers, warehouse automation holds the promise of enhanced distribution efficiency and reduced costs, enabling them to remain competitive in an evolving market.