Pivot Wheel Sorters provide one of the highest flexibility and modularity among line sorting systems. They are easily configurable and can be expanded at any time by simply adding additional diverter modules and connecting conveyor sections.

The operating mechanism of Pivot Wheel Sorters sets the industry standard for robustness, performance, and reliability, thanks to the integration of a dedicated 48v drum motor within each wheel unit. This design not only maximises performance but also significantly enhances reliability by eliminating single points of failure within the wheel configuration. Additionally, maintenance is streamlined, as each wheel can be independently removed and replaced within minutes, ensuring minimal downtime.

Benefits of Pivot Wheel Sorters

Some of the benefits of using pivot wheel sorters are listed below:

1️⃣ “Soft sorting” mode

There is no need to turn over the tray or tilt parcels at a large angle to unload, fragile items can be easily sorted

2️⃣ Flexible deployment

Can be used in combination with belt conveyors to transport goods for sorting

3️⃣ Heavy-duty transport

Maximum load capacity of up to 80kg/㎡ (depending on selected model), greatly reducing manpower and improving sorting efficiency

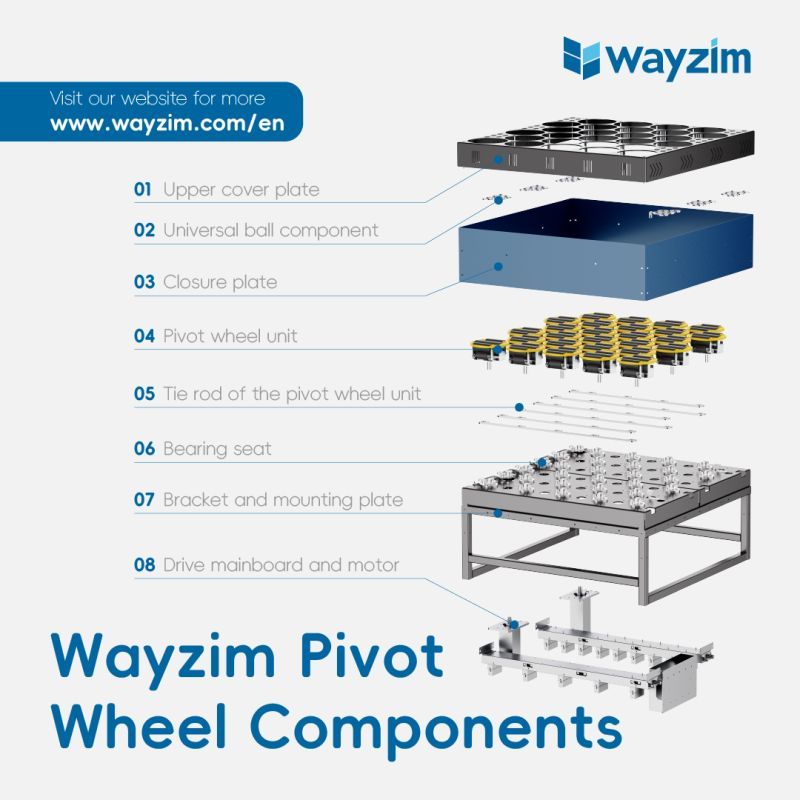

Pivot Wheel Components

The main components that make up the pivot wheel unit are listed below:

1️⃣ Rows of motorised rollers within the pivot wheel are organised into groups, with the number of groups determined by the specific configuration. These groups are connected to a steering mechanism, which is powered by a servo motor. When the main controller sends the steering signal, the servo motor actuates the steering plate and pull rot, enabling the entire unit to perform precise directional movements.

2️⃣ The number of servo motors used in each Pivot Wheel model is determined by the specific throughput and performance requirements of the application. Wayzim offers an extensive range of Pivot Wheel Diverter models, each tailored to various application scenarios.

Pivot Wheel Operating Principle

The operating principle of pivot wheel diverters is very simple, a PEC (Photoelectric senor) is deployed just before the diverter unit, then as the parcel triggers the PEC, the signal is transferred to the pivot wheel unit which then executes the tilting action.

In summary, Pivot Wheel Sorters offer a precise and efficient solution for logistics sorting. With modular components and a simple operating principle, they meet diverse needs, providing customisable performance for high throughput and precise sorting.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.