In the fast-paced world of logistics and warehouse management, dimensioning weighing scanning systems have emerged as pivotal tools. These systems accurately measure the size, weight, and volume of packages, optimising freight operations and reducing shipping costs. By integrating dimensioning, weighing, and scanning into one seamless process, companies can ensure efficiency and accuracy in their shipping and handling processes.

The Significance of Dimensioning Weighing Scanning Systems

Dimensioning weighing scanning systems are essential for businesses looking to streamline operations and enhance logistical efficiency. These systems provide precise data that are critical for maximising storage space, optimising shipping costs, and improving load planning. The accuracy offered by these integrated systems ensures that businesses can avoid costly shipping errors and chargebacks from carriers due to incorrect shipment information.

How Dimensioning Weighing Scanning Systems Work

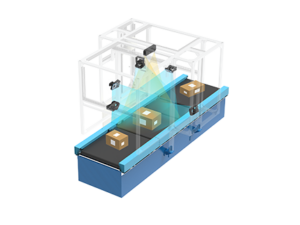

These systems utilise advanced sensors and imaging technologies to capture and record the dimensions and weight of packages. The integrated scanning component further adds the capability to read barcodes and other identification marks, which is essential for inventory management and traceability. This comprehensive data capture facilitates better decision-making and efficient resource management in supply chain operations.

RELATED: How Does the Dynamic DWS System Enhance Operational Efficiency in Logistics Businesses?

Key Components of Effective Systems

- Dimensioning: Utilises laser scanners or infrared beams to capture the exact dimensions of a package.

- Weighing: Employs high-precision scales to determine the weight of the package accurately.

- Scanning: Uses barcode readers to capture and process information related to the package’s contents and destination.

Benefits of Dimensioning Weighing Scanning Systems

Implementing dimensioning weighing scanning systems in your logistics can dramatically enhance operational efficiency. These systems not only provide critical data that helps in space planning and route optimisation but also ensure compliance with carrier pricing policies. The automation of these measurements reduces human error, ensuring more accurate billing and inventory tracking.

Applications in Various Industries

From retail to manufacturing, and from distribution centres to shipping companies, these systems are versatile. In retail, they ensure that all packaged goods are measured and weighed correctly before dispatch. In manufacturing, they help in maintaining inventory accuracy and managing material use efficiently.

Optimising Your Operations with Dimensioning Weighing Scanning Systems

To fully benefit from dimensioning weighing scanning systems, it’s essential to integrate them properly into your IT ecosystem. Compatibility with existing warehouse management software (WMS) and transportation management systems (TMS) will leverage the full potential of real-time data processing and information sharing.

RELATED: DWS: Streamlining Logistics with Dynamic Dimensioning, Weighing, and Scanning.

Choosing the Right System

When selecting a dimensioning weighing scanning system, consider factors such as:

- Compatibility with existing systems

- Ease of integration

- Scalability to future needs

- Accuracy and reliability of data

- Speed of operation

FAQs About Dimensioning Weighing Scanning Systems

What are dimensioning weighing scanning systems? Dimensioning weighing scanning systems are integrated solutions that measure the size, weight, and scan the barcode of packages. These systems streamline various processes in logistics and warehouse management by providing accurate, reliable data quickly.

How do dimensioning systems improve warehouse operations? They optimise space utilisation by providing accurate package dimensions, facilitate accurate shipping documentation, and improve overall inventory management through precise measurement and data integration.

Can these systems be integrated with existing WMS and TMS? Yes, most modern dimensioning weighing scanning systems are designed to be compatible with existing Warehouse Management Systems (WMS) and Transportation Management Systems (TMS), allowing for seamless data flow and enhanced operational efficiency.

What should I look for when choosing a dimensioning weighing scanning system? Key factors include the accuracy of the system, compatibility with existing logistics software, ease of use, scalability, and the ability to process a wide range of package sizes and weights efficiently.

Are there different types of dimensioning weighing scanning systems available? Yes, systems vary based on the technologies used for dimensioning and weighing, the type of scanning capabilities they offer, and the specific operational needs they cater to, such as industrial use or retail environments.

By integrating dimensioning weighing scanning systems into your logistics operations, you not only enhance efficiency but also contribute to more sustainable practices by optimising resource use and reducing waste. This smart technology is an investment in the future of automated, data-driven logistics.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.