In the fast-paced world of logistics and supply chain management, efficiency and accuracy are paramount. Companies are constantly seeking innovative solutions to streamline their operations and reduce overheads. One such groundbreaking technology that has been making waves is the Dimension Weigh Scan (DWS) system. This technology has not only transformed the way packages are processed but has also set new standards for operational efficiency.

What are DWS Systems?

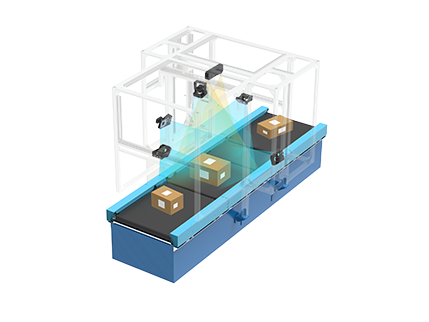

At its core, a DWS system is an advanced technology used in the logistics and warehouse sectors to capture a package’s dimensions, weight, and scan the barcode automatically. This integration of dimensioning, weighing, and scanning into a single system offers a multifaceted solution that significantly enhances data accuracy and processing speed. By implementing DWS systems, companies can ensure that their cargo handling is as efficient and error-free as possible.

RELATED: The Dynamic DWS System

The Role of DWS Systems in Modern Logistics

The adoption of DWS technology is not just about upgrading to the latest equipment; it’s about rethinking the way logistics operates. These systems facilitate real-time data collection, which is crucial for inventory management, space utilisation, and optimal route planning. In an era where e-commerce is booming, the ability to quickly and accurately process orders can be the difference between leading the market and lagging behind.

Enhancing Efficiency with Dimension Weigh Scan DWS Systems

One of the key benefits of DWS systems is their ability to enhance operational efficiency. These systems automate the measurement and data entry processes, which reduces manual labor and minimises the risk of human error. This automation is especially beneficial in high-volume shipping environments, where the speed of package processing directly impacts the bottom line.

Cost Reduction Through Accurate Billing

DWS technology also plays a crucial role in cost management. Accurate dimension and weight data ensure that shipping costs are calculated correctly, preventing revenue loss due to undercharging for shipment space. Additionally, this accuracy aids in optimising container space, allowing for more effective load planning and reduced transportation costs.

The Technical Side of DWS Systems

Understanding the technical aspects of DWS systems is crucial for their successful implementation. These systems use a combination of sensors, cameras, and laser scanning technologies to capture data. The integration of this technology requires a strategic approach, ensuring that the systems are compatible with existing warehouse management software (WMS) and transportation management systems (TMS).

Implementing DWS Technology: Best Practices

When implementing DWS systems, it’s important to follow best practices to maximise their potential. This includes conducting a thorough needs assessment, selecting a system that integrates seamlessly with existing operations, and providing adequate training for staff. Ensuring the system’s scalability is also crucial as your business grows and the volume of shipments increases.

RELATED: DWS: Streamlining Logistics with Dynamic Dimensioning, Weighing, and Scanning.

FAQs on DWS Systems

Q: How does a DWS system improve shipping accuracy?

A: By automatically capturing package dimensions, weight, and barcode information, DWS systems minimise manual data entry errors and ensure that shipping information is precise and reliable.

Q: Can DWS systems integrate with existing warehouse management systems?

A: Yes, most modern DWS systems are designed to integrate smoothly with existing WMS and TMS platforms, facilitating seamless data flow and improving overall operational efficiency.

Q: Are DWS systems suitable for all types of logistics operations?

A: While DWS systems offer significant benefits for a wide range of logistics operations, their suitability may vary based on specific business needs and the volume of shipments processed.

Q: What is the ROI of implementing a DWS system?

A: The return on investment can vary, but companies often see significant savings through reduced labor costs, improved accuracy, and optimised shipping costs. The efficiency gains alone can justify the investment within a relatively short period.

Q: How do DWS systems contribute to sustainability in logistics?

A: By optimising package dimensions and weight data for loading, DWS systems can help reduce the number of vehicles required for transportation, thereby lowering fuel consumption and carbon emissions.

In the landscape of modern logistics, the implementation of DWS systems marks a significant leap towards operational excellence. By embracing this technology, businesses can not only achieve greater efficiency and accuracy but also gain a competitive edge in the ever-evolving world of e-commerce and supply chain management. With the continuous advancements in dimension weigh scan technology, the future of logistics looks brighter and more efficient than ever.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.