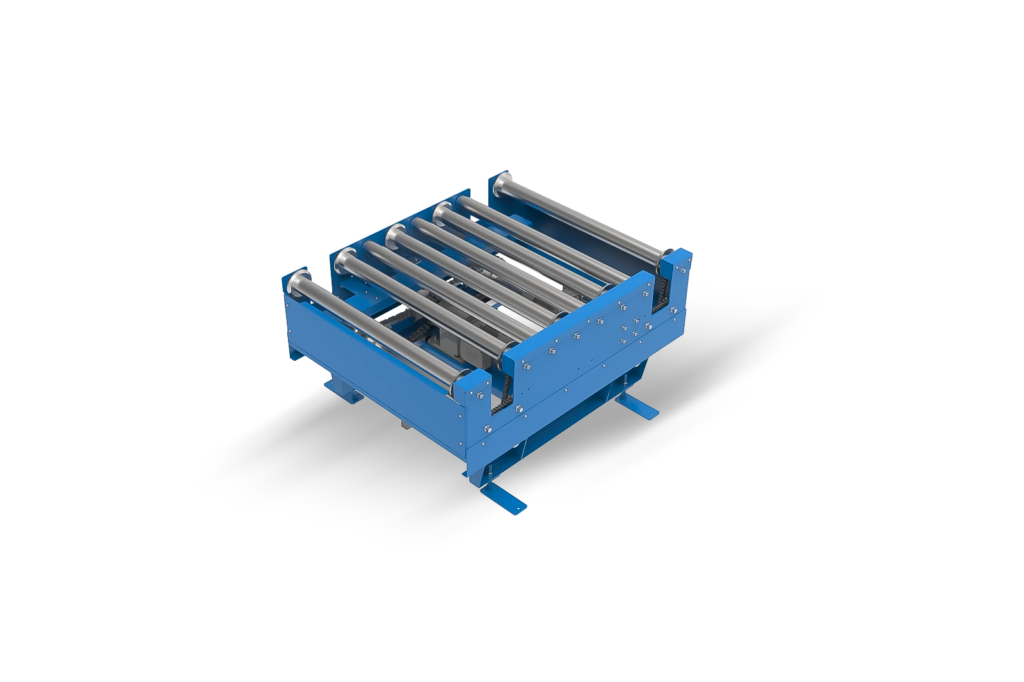

The Pop-up Sorter, also known as a Strip Belt Sorter, is a versatile and innovative piece of equipment used in modern warehouses and distribution centres. It combines the speed and flexibility of a conveyor belt with the space-saving benefits of a vertical sorting system, making it a valuable tool for efficient order fulfillment.

What is a Pop-up Sorter?

Imagine a series of individual belt segments embedded flush within a conveyor belt. These segments can be raised and lowered on demand, creating temporary “diverts” that guide packages towards specific sorting destinations. This unique design allows for efficient sorting and routing of items without requiring complex and space-consuming systems.

Benefits of Pop-up Sorters

- High sorting speed: Individual pop-up segments can be activated and retracted quickly, enabling fast and efficient sorting of packages.

- Increased flexibility: The modular design allows for easy configuration changes to adapt to different sorting requirements and product types.

- Reduced space requirements: Pop-up sorters occupy a smaller footprint compared to traditional conveyor systems with dedicated diverters.

- Gentle product handling: The smooth belt surfaces minimise the risk of damage to delicate items.

- Cost-effectiveness: Compared to more complex sorting systems, pop-up sorters offer a cost-effective solution for smaller to medium-sized warehouses.

- Scalability: The system can be easily expanded by adding additional pop-up modules as your sorting needs grow.

How does it work?

- Packages are loaded onto the main conveyor belt and scanned to identify their sorting destination.

- The control system determines the appropriate pop-up segment location based on the scan data.

- The designated pop-up segment elevates, creating a temporary divert on the conveyor belt.

- As the package reaches the pop-up segment, it is gently guided off the main conveyor belt and onto a chute for conveyor line leading to its designated sorting bin.

- Once the package is diverted, the pop-up segment retracts back into the belt, allowing other packages to pass uninterrupted.

Applications of Pop-up Sorters

- E-commerce fulfillment centres: Efficiently sorting smaller packages with a moderate number of sorting destinations.

- Retail distribution centres: Organising and distributing packages for various stores.

- Postal sorting facilities: Rapidly sorting and routing mail for timely delivery.

- Manufacturing and production lines: Directing products towards different stages of the production process.

- Warehouses with limited space: Optimising sorting efficiency within compact warehouse layouts.

Types of Pop-up Sorters

- Chain-driven: Utilising chains to raise and lower the pop-up segments.

- Belt-driven: Employing belts for smoother and quieter operation.

- Single-mast: Suitable for smaller warehouses and lower sorting heights.

- Double-mast: Offer higher speeds and throughput for larger warehouses and higher sorting heights.

Future of Pop-up Sorters

The future of Pop-up Sorters is driven by advancements in technology.

- Integration with automation: Combining pop-up sorters with robotic arms for automated loading and unloading of packages.

- Smart pop-up technology: Utilising sensors and cameras to identify and handle diverse package types with improved accuracy.

- Predictive maintenance: Utilising real-time data to predict potential issues and optimise system uptime.

These advancements will ensure that Pop-up Sorters remain a relevant and valuable tool in the ever-evolving world of warehouse automation, providing a flexible and efficient solution for smaller to medium-sized sorting operations.

Empower your logistics with SmartlogitecX, fueled by WayZim Technologies. As leaders in Warehouse Automation for the Australian market, we’re dedicated to delivering efficiency and innovation right to your doorstep. SmartlogitecX’s approach is two-fold: globally informed, locally applied. Take the first step towards optimised operations by reaching out to our sales team for a solution that speaks directly to your needs.