In the fast-paced world of logistics and e-commerce, efficiently handling and processing bulk flows of diverse items is crucial for timely order fulfillment. The 2D Bulk Flow Singulator (BFS) emerges as a powerful warehouse solution, offering a cost-effective and adaptable way to separate individual items from a disorganised pile.

What is a 2D Bulk Flow Singulator?

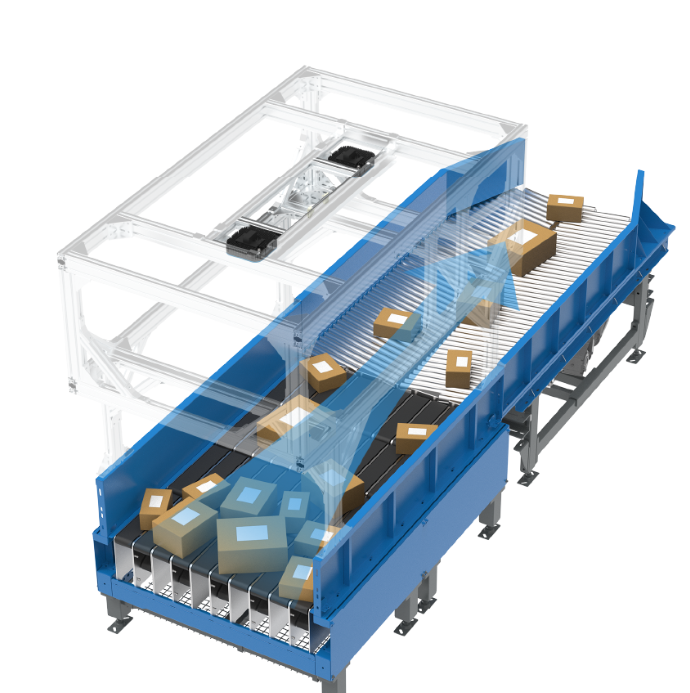

Imagine a conveyor belt feeding a pile of mixed products—parcels, boxes, books, etc. The 2D Bulk Flow Singulator utilises a combination of technology and mechanical components to identify and separate each item from the bulk flow. This allows for efficient singulation, ensuring accurate picking and packing for individual orders.

How does it work?

- Bulk flow entry

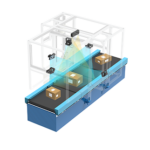

Products are loaded onto the conveyor belt, creating a disorganised pile. - Image capture

High-resolution cameras capture an overhead image of the pile, providing a 2D view of each item’s position and dimensions. - Algorithm analysis

Advanced algorithms analyse the image data to identify individual items and determine the optimal separation strategy. - Robotic control

Precise robotic arms equipped with vacuum grippers or other tools are programmed to move based on the algorithm’s instructions. - Singulation

Robots carefully pick and lift individual items from the pile, separating them from the bulk flow. - Item transfer

The separated items are transferred to designated sorting bins, conveyor lines, or packing stations.

Benefits of 2D Bulk Flow Singulators

- Increased throughput

2D Bulk Flow Singulator significantly improve singulation speed compared to manual methods, leading to faster processing and higher order fulfillment rates. - Reduced labor costs

Automation eliminates the need for dedicated manual labor for picking and separating items, lowering operational costs. - Improved accuracy

Precise vision technology and algorithms minimise the risk of misidentification or damage to items during singulation. - Enhanced flexibility

2D BFS can handle a wide variety of item sizes, shapes, and materials, adapting to diverse inventory profiles. - Space efficiency

Compact systems optimise space utilisation within warehouses and distribution centres. - Scalability

The system can be easily scaled to accommodate changing volume requirements and business growth.

Applications of 2D Bulk Flow Singulators

- E-commerce fulfillment centres

Handling a high volume of diverse items with varying sizes and shapes. - Parcel-sorting facilities

Efficiently sorting and routing packages for faster delivery. - Retail distribution centres

Managing and distributing various products for different stores. - Manufacturing and production lines

Separating components and parts for assembly processes. - Warehouses with limited space

Optimising storage utilisation and improving space management.

Future of 2D Bulk Flow Singulators

Continued advancements in technology are shaping the future of 2D Bulk Flow Singulators.

- Integration with AI and machine learning: Optimising singulation algorithms for increased accuracy and handling capabilities.

- Advanced vision systems: Utilising 3D cameras and sensors for enhanced depth perception and item identification.

- Collaborative robots (cobots): Implementing robots that safely interact with humans, further automating singulation and packing tasks.

These advancements will ensure that 2D Bulk Flow Singulators remain a vital tool for modern logistics operations, providing a flexible and efficient solution to streamline singulation and optimise order fulfillment across various industries.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australia and New Zealand markets. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.