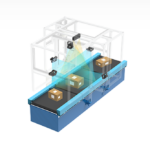

A 3D Bulk Flow Singulator (BFS) is a revolutionary automation technology designed to efficiently handle and separate unorganised piles of parcels, boxes, and other items in a warehouse environment. It tackles the challenge of “singulating,” meaning separating individual items from a bulk flow without damaging them or disrupting the overall workflow.

How does it work?

The 3D Bulk Flow Singulator utilises a combination of hardware and software components to achieve precise singulation –

3D vision sensors: High-resolution cameras and depth sensors capture a detailed 3D image of the bulk flow, identifying and locating individual items within the pile.

Proprietary algorithms: Advanced algorithms analyse the 3D data to determine the optimal separation strategy for each item based on its size, shape, and position.

Robotic manipulators: Precisely controlled robotic arms equipped with vacuum grippers or other tools carefully lift and separate individual items from the bulk flow.

Intelligent control system: The system coordinates the vision sensors, algorithms, and robots to ensure smooth and efficient singulation process.

Key benefits of 3D BFS

Increased throughput: 3D BFS significantly improves singulation speed and efficiency compared to manual methods, leading to faster processing and higher order fulfillment rates.

Reduced labor costs: Automating the singulation process eliminates the need for dedicated manual labor, lowering operational costs and freeing up employees for higher-value tasks.

Improved accuracy and reduced damage: Precise vision technology and intelligent algorithms minimise the risk of misidentification or damage to items during singulation.

Enhanced space utilisation: 3D Bulk Flow Singulator can handle items in a more compact and organised manner, optimising space utilisation within the warehouse.

Increased scalability: The system can be easily scaled to accommodate varying item sizes, shapes, and volumes, adapting to changing business needs.

Applications of 3D BFS

E-commerce fulfillment centres: Handling a high volume of diverse items with varying sizes and shapes.

Parcel sorting facilities: Efficiently sorting and routing packages for faster delivery.

Warehouses with limited space: Optimising storage utilisation and improving space management.

Manufacturing and production lines: Automating the singulation of parts and components for assembly lines.

Comparison to 2D Bulk Flow Singulators

Traditional 2D Bulk Flow Singulator systems rely solely on overhead cameras and can only identify and separate items based on their 2D image, limiting their accuracy and handling capabilities. 3D Bulk Flow Singulator technology offers significant advantages by providing a complete 3D understanding of the bulk flow, allowing for more precise and efficient singulation of a wider range of items.

Future of 3D BFS

The development of artificial intelligence (AI) and machine learning (ML) is further enhancing the capabilities of 3D Bulk Flow Singulator. AI-powered algorithms are becoming increasingly adept at recognising and adapting to different item types and handling situations, leading to even greater accuracy, efficiency, and flexibility.

3D Bulk Flow Singulators represent a significant breakthrough in warehouse automation technology. Their ability to seamlessly and efficiently handle diverse items in bulk offers a powerful solution to optimise logistics operations, improve productivity, and reduce costs. As the demand for faster and more efficient supply chains continues to grow, 3D Bulk Flow Singulator technology is poised to play a crucial role in shaping the future of the logistics industry.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australia and New Zealand markets.Transform your warehouse operations with our specialised technology.

Interested in advancing your logistics? Contact our SmartlogitecX sales team for a customised automation solution.