In the bustling realm of warehouse automation, pallet roller conveyors stand as a ubiquitous and essential component, facilitating the efficient movement and handling of palletised goods. These robust and versatile systems seamlessly integrate into warehouse layouts, providing a reliable and cost-effective solution for transporting pallets across various distances and elevations.

Key Features and Advantages of Pallet Roller Conveyors

Pallet roller conveyors offer a range of advantages that make them a compelling choice for warehouse automation:

- Durability and Reliability

Pallet roller conveyors are constructed from heavy-duty materials, ensuring long-lasting performance and resistance to wear and tear in demanding warehouse environments. - Versatility

Pallet roller conveyors can handle a wide range of pallet sizes and weights, making them adaptable to various warehouse applications. - Scalability

Pallet roller conveyors can be easily expanded and modified to accommodate changing warehouse needs and growing inventory levels. - Reduced Labor Costs

Automated pallet movement eliminates the need for manual labor, leading to lower labor costs and improved operational efficiency. - Enhanced Safety

Pallet roller conveyors operate autonomously, minimising the risk of workplace accidents and injuries associated with manual pallet handling.

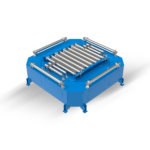

Types of Pallet Roller Conveyors

Pallet roller conveyors come in various types to suit specific warehouse needs:

- Gravity Roller Conveyors

Gravity roller conveyors utilise an inclined surface to move pallets using gravity, making them an energy-efficient option for transporting pallets over short distances. - Powered Roller Conveyors

Powered roller conveyors employ electric motors to drive the rollers, allowing for the movement of pallets across horizontal and inclined surfaces. - Combination Roller Conveyors

Combination roller conveyors combine gravity and powered sections, providing flexibility in transporting pallets over varying distances and elevations.

Applications and Use Cases of Pallet Roller Conveyors

Pallet roller conveyors are widely used in various industries and applications, including:

- Retail Warehouses

Pallet roller conveyors play a crucial role in retail warehouses for moving palletised goods from receiving areas to storage racks, picking lines, and shipping docks. - Manufacturing Facilities

Pallet roller conveyors are employed in manufacturing facilities to transport palletised raw materials, components, and finished goods within production lines and storage areas. - Food and Beverage Distribution Centres

Pallet roller conveyors are essential in food and beverage distribution centres for handling palletised food products and beverages. Their controlled environment ensures the integrity and safety of these perishable items.

Future Trends in Pallet Roller Conveyor Technology

The future of pallet roller conveyor technology is poised for advancements, driven by the demand for increased efficiency, flexibility, and integration in warehouse operations.

Key trends include:

- Smart Roller Conveyors

Smart roller conveyors will incorporate sensors and communication capabilities, enabling real-time tracking of pallets, monitoring of conveyor health, and integration with warehouse management systems. - Enhanced Robotics and Automation

Pallet roller conveyors will integrate with advanced robotics and automation technologies to further improve pallet handling precision, speed, and adaptability to changing pallet sizes and configurations. - Data Analytics and Predictive Maintenance

Pallet roller conveyors will leverage data analytics and machine learning to predict maintenance needs, optimise conveyor performance, and prevent downtime, ensuring continuous operation and optimal system utilisation.

Pallet roller conveyors represent a valuable tool in the modern warehouse and distribution centre, streamlining material handling operations, enhancing productivity, and reducing labor costs. As technology advances, pallet roller conveyors will become even more sophisticated and efficient, further revolutionising the way goods are handled and moved throughout the supply chain.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.